Self-adsorption solenoid valve driving device for reinforced-exhaustion gas water heater

A solenoid valve drive, gas water heater technology, applied in the field of electricity, can solve problems such as safety accidents, solenoid valves cannot be closed, and gas out of control

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0029] A further detailed description will be made below in conjunction with the accompanying drawings and embodiments of the present invention:

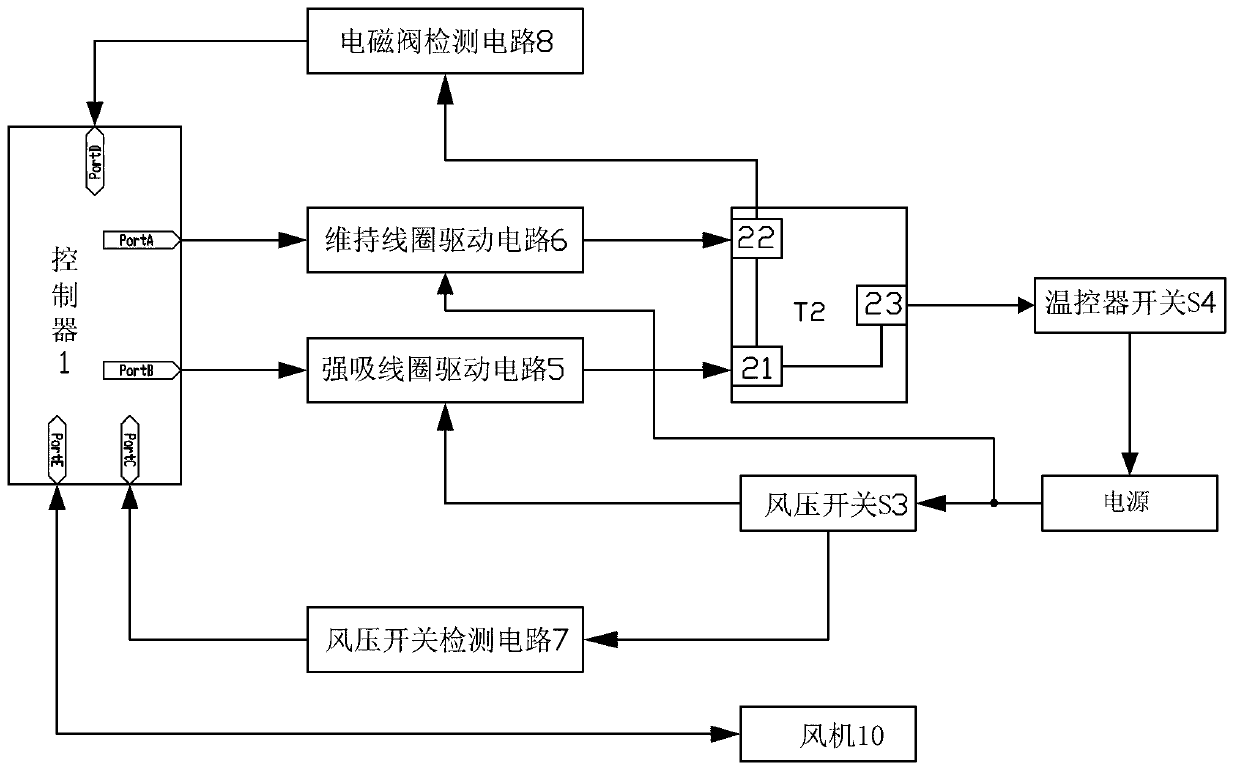

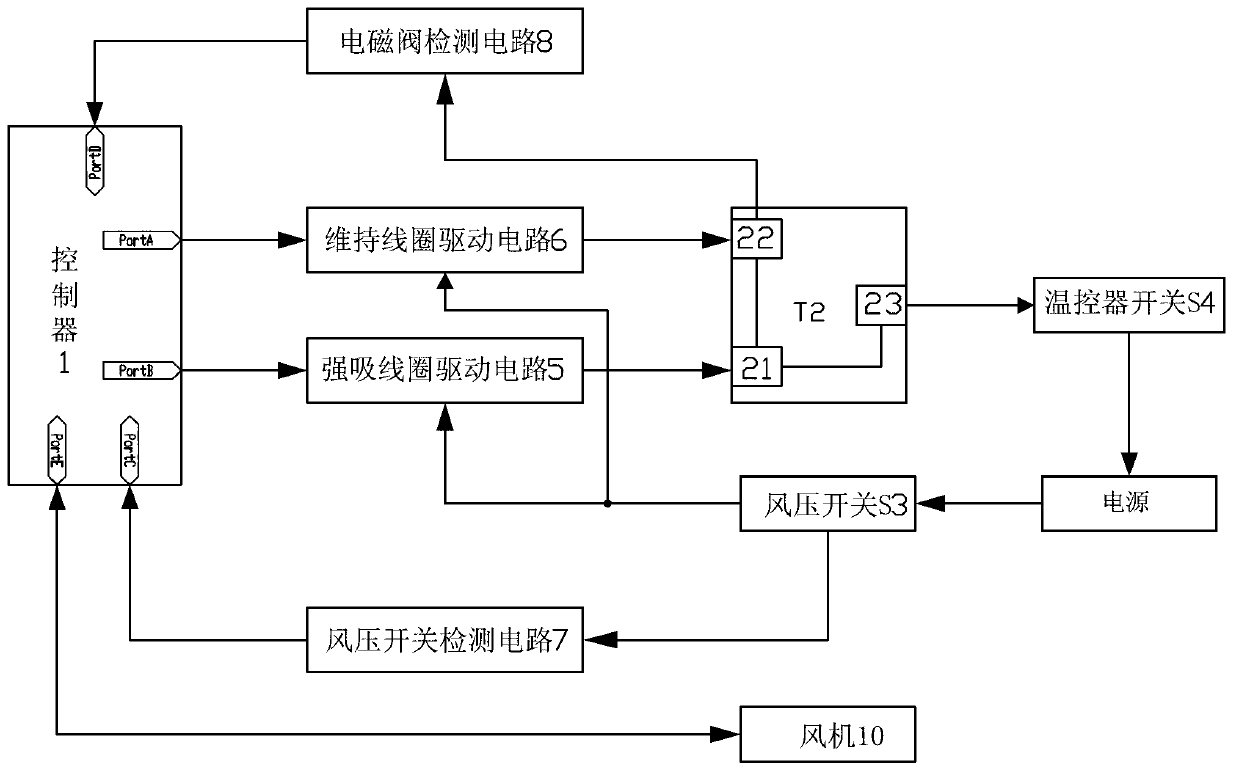

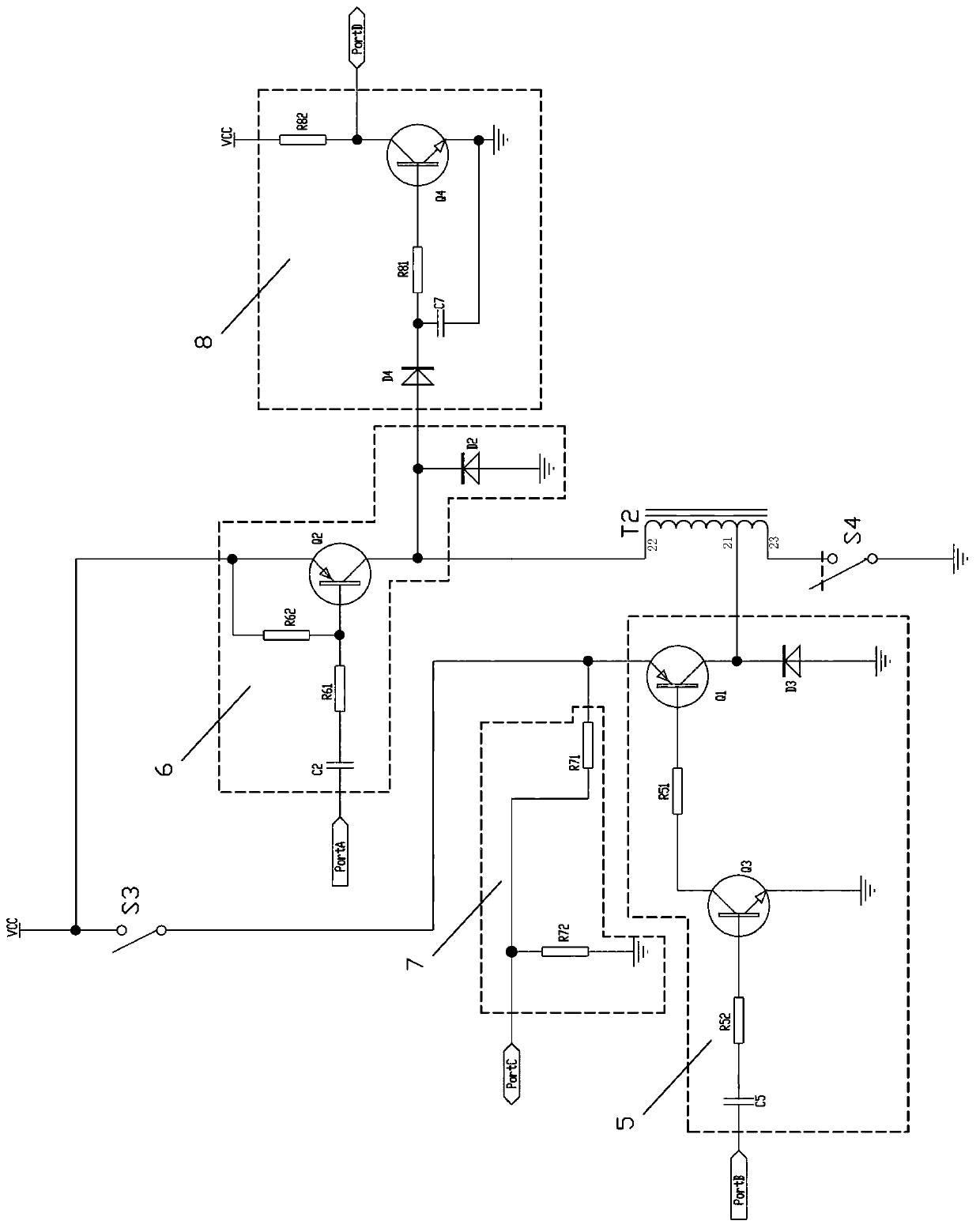

[0030] like figure 1 As shown, a self-priming solenoid valve driving device for a forced exhaust gas water heater includes a controller 1, a solenoid valve T2, a wind pressure switch S3, and a thermostat switch S4. The solenoid valve T2 coil is provided with a solenoid valve Strong suction end 21, solenoid valve maintenance end 22 and solenoid valve common end 23, the solenoid valve common end 23 is connected to the positive pole through the thermostat switch S4, one end of the wind pressure switch S3 is connected to the negative pole of the power supply, and the wind pressure switch S3 A wind pressure switch detection circuit 7 is connected between the other end and the controller 1, and a strong suction coil driving circuit 5 for driving the solenoid valve T2 to be connected is connected between the controller 1 and the strong suc...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com