Adhesive dispensing quality visual detection method based on robot intelligent terminal

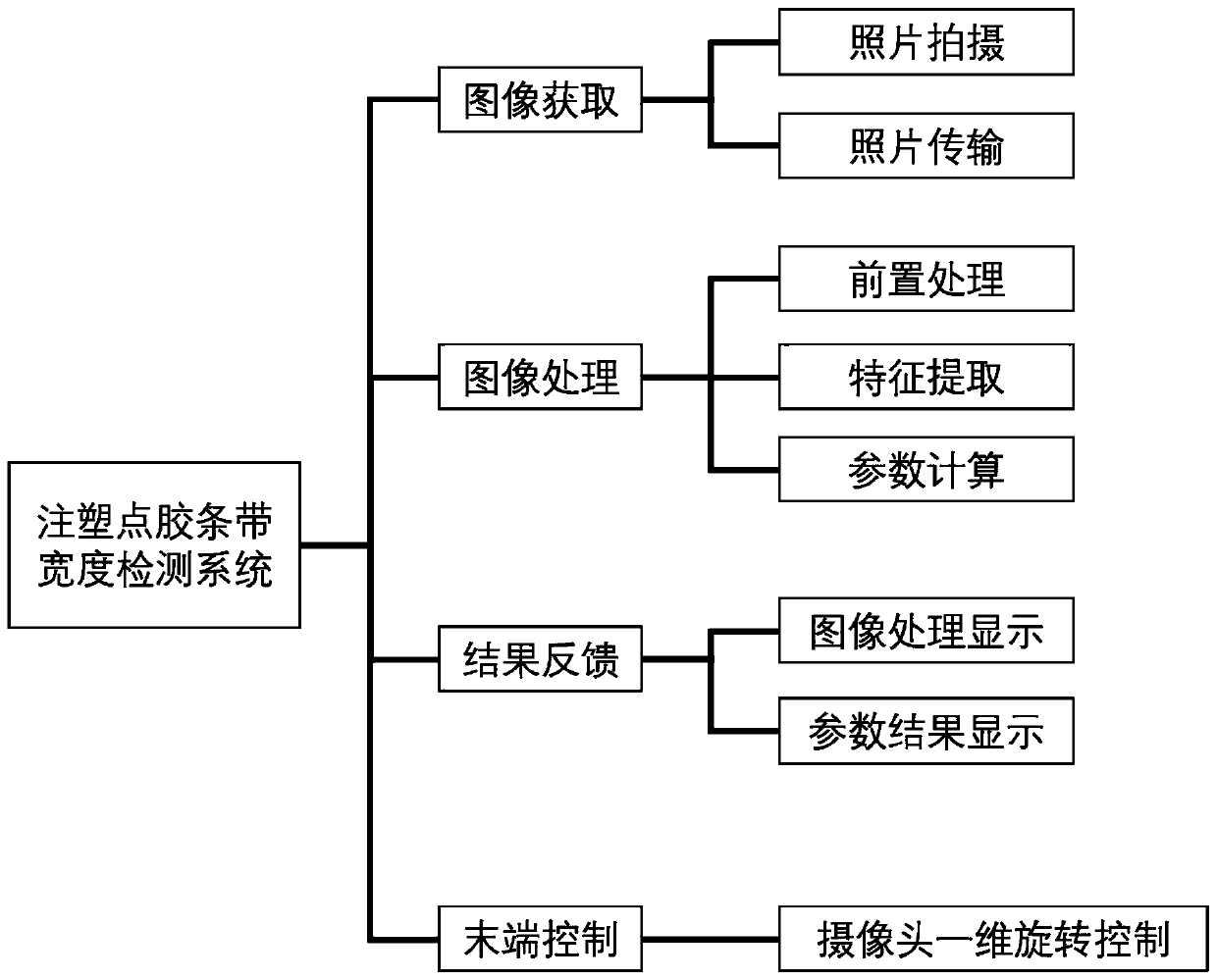

A technology of robotic intelligence and visual inspection, applied in instruments, image data processing, computing, etc., can solve problems such as low efficiency, high process cost, and dependence on manual inspection, and achieve the effect of improving inspection efficiency and reducing labor costs

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

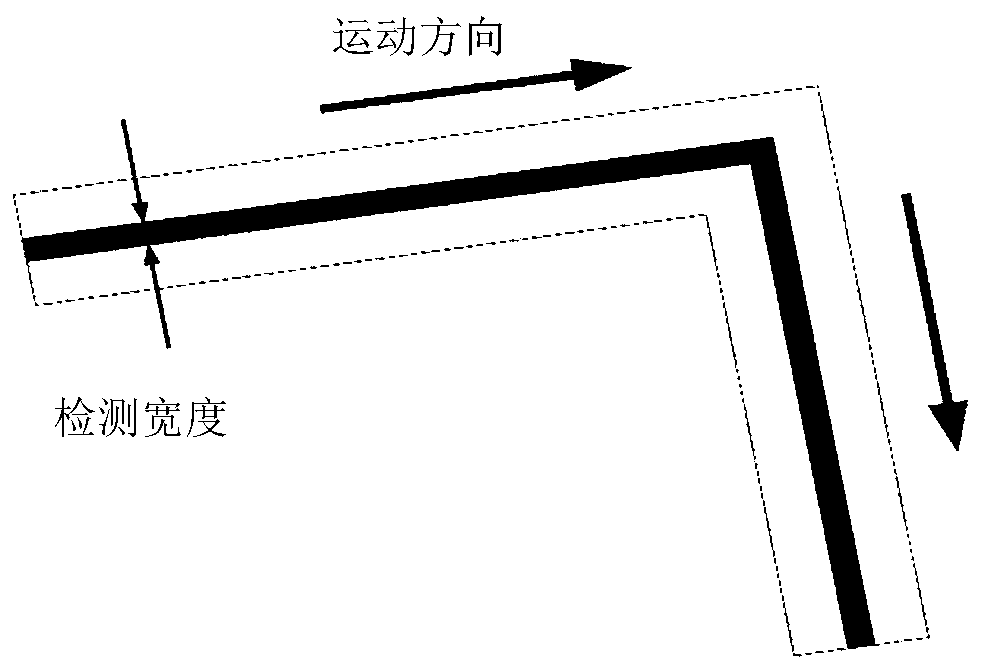

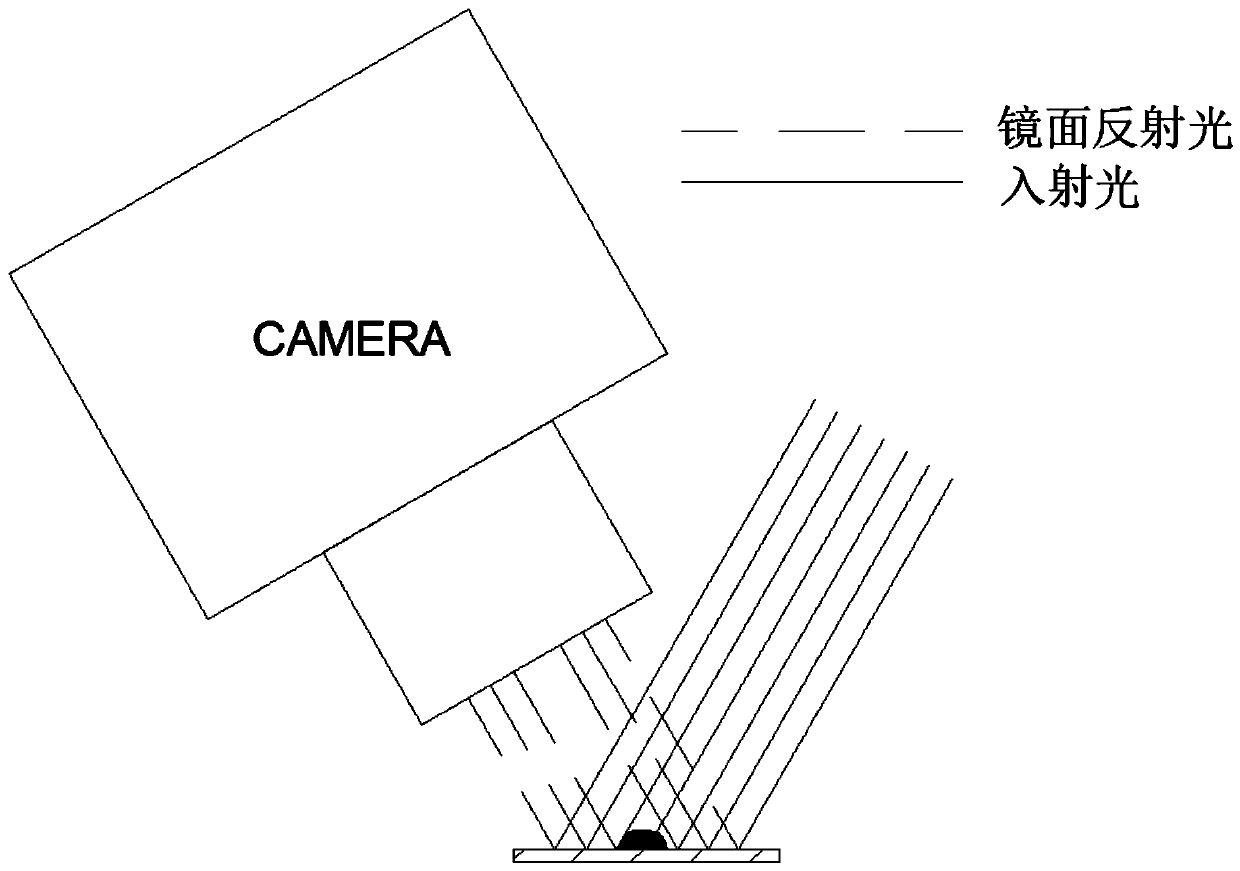

[0063] Embodiment: use this detection method to realize the detection of the side glue dispensing quality of the injection molding frame, and complete the quality evaluation. The available inspection images (grayscale) taken by the camera are as Image 6 ; Perform Gaussian filtering on the basis of the grayscale image and set the threshold to binarize the image as Figure 7 ; And traverse the pixels according to the idea to know the maximum width and average width of the features in the image, such as Figure 8 . In addition, find the minimum circumscribed rectangle of the feature to find its fitting straight line and calculate the error value of the previous width measurement, and feed back all the above-mentioned measured results to the window interface such as Figure 9 .

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com