Airflow sampling method and device for grain in grain depot

A sampling device and grain depot technology, applied in the direction of sampling device, etc., can solve the problem of ineffective sampling and other problems, and achieve the effect of good promotion and use value, cost economy and effective method.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

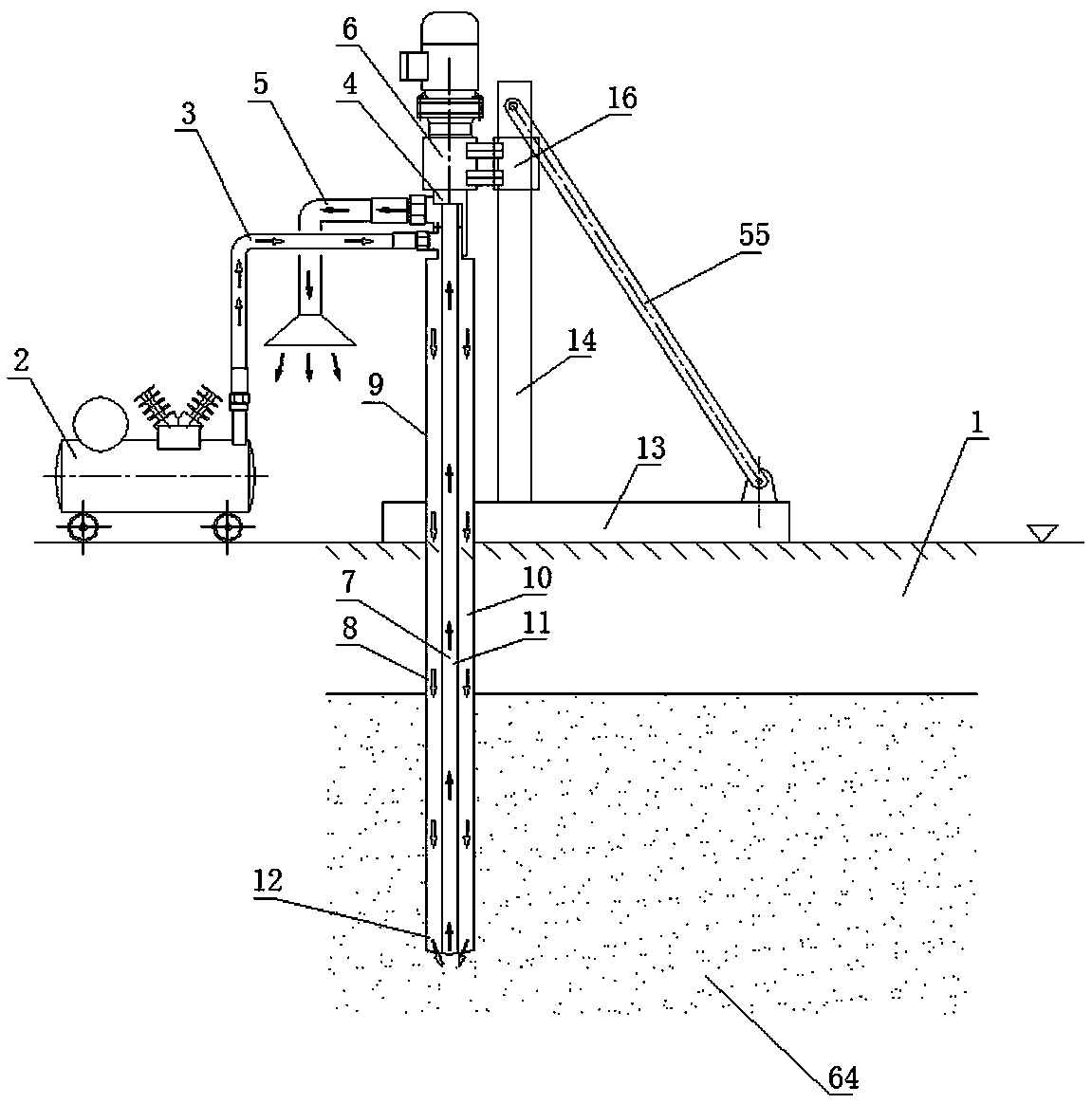

[0106] Below in conjunction with accompanying drawing, the airflow sampling device of grain depot of the present invention is described in detail below.

[0107] As shown in the accompanying drawings, the airflow sampling device for grain in the grain depot of the present invention has a structure including an air compressor 2 above the grain depot 1 (or peripheral), a gyrator 6, a sampling faucet 4, and a sampling pipe 9.

[0108] An air compressor 2 is arranged on the base 13 on the top surface of the grain depot 1, and the output high-pressure air pipeline 3 of the air compressor 2 is connected to the sampling faucet 4,

[0109] Sampling faucet 4 outputs grain sample collection pipeline 5,

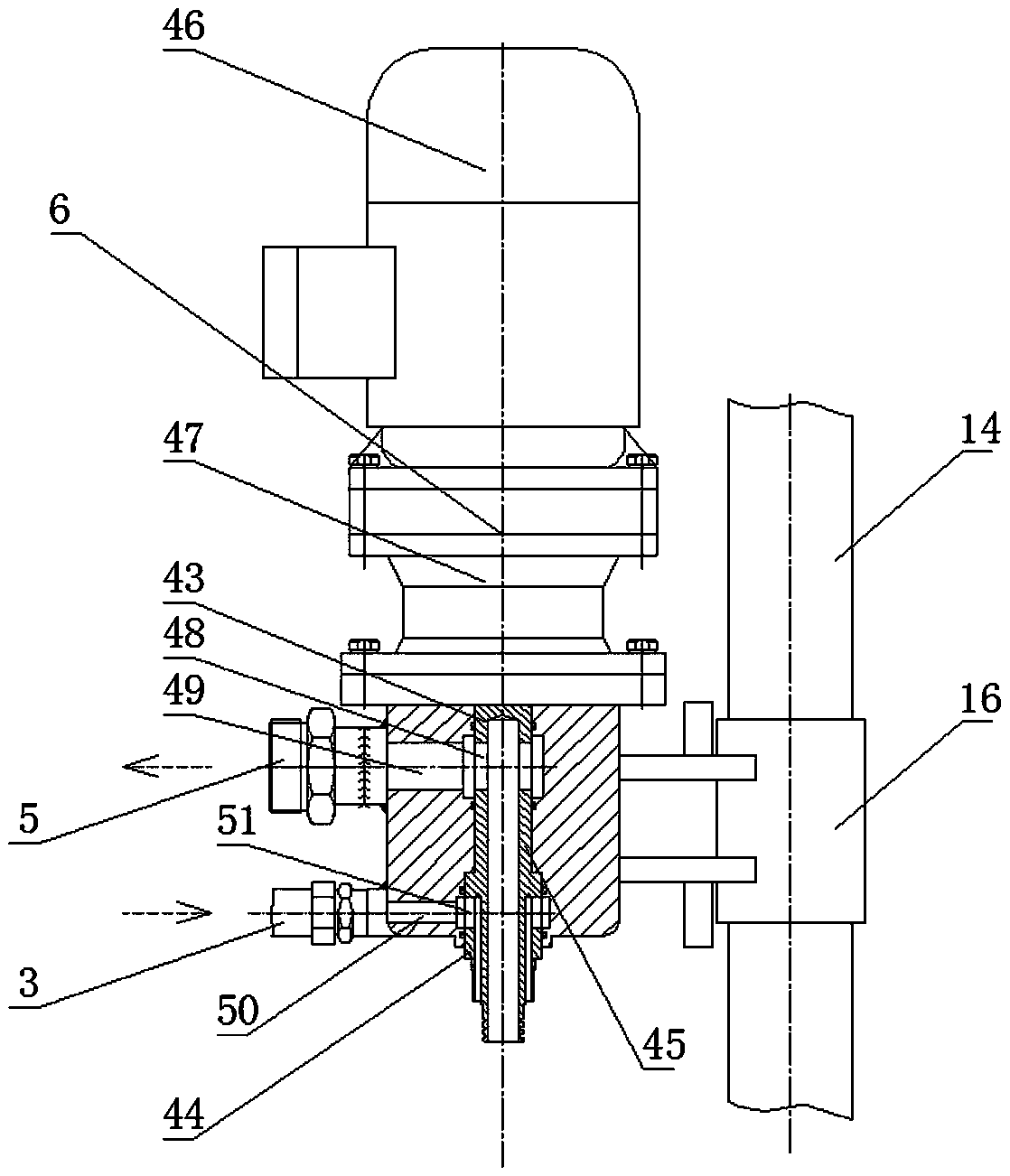

[0110] The top of the sampling faucet 4 is connected with a gyrator 6, the sampling faucet is set as a sampling tube composed of an inner tube 7 and an outer tube 8, and the gyrator 6 drives the sampling tube 9 to rotate; the high-pressure air pipeline 3 is connected between the outer t...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com