Arrangement and method for heating an electrical conductor

A technology for electrical conductors and equipment, applied in the field of equipment and methods for heating electrical conductors, can solve the problems of heavy coils, expensive, difficult to clean and maintain, and achieve the effect of easy maintenance and effective methods

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

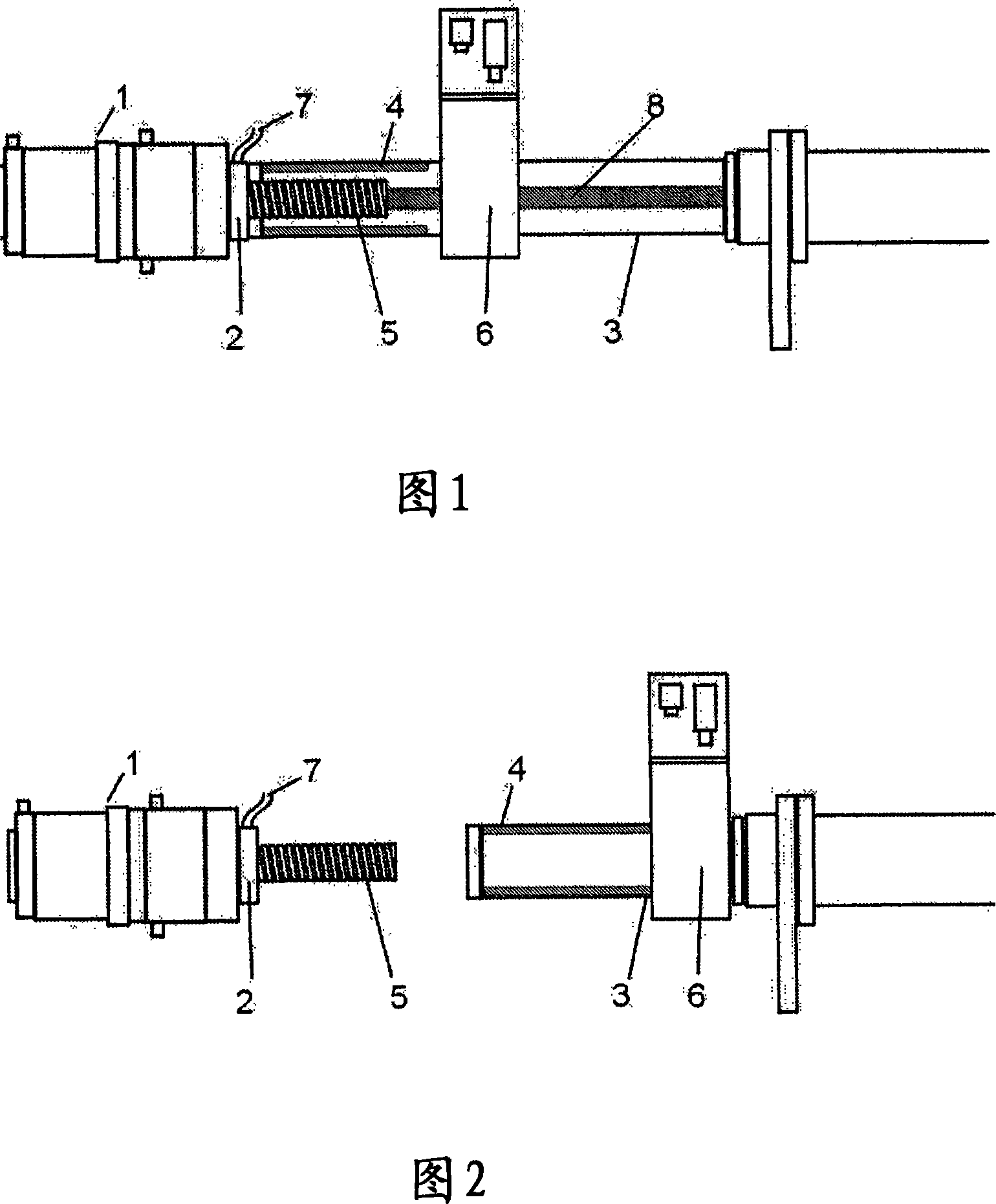

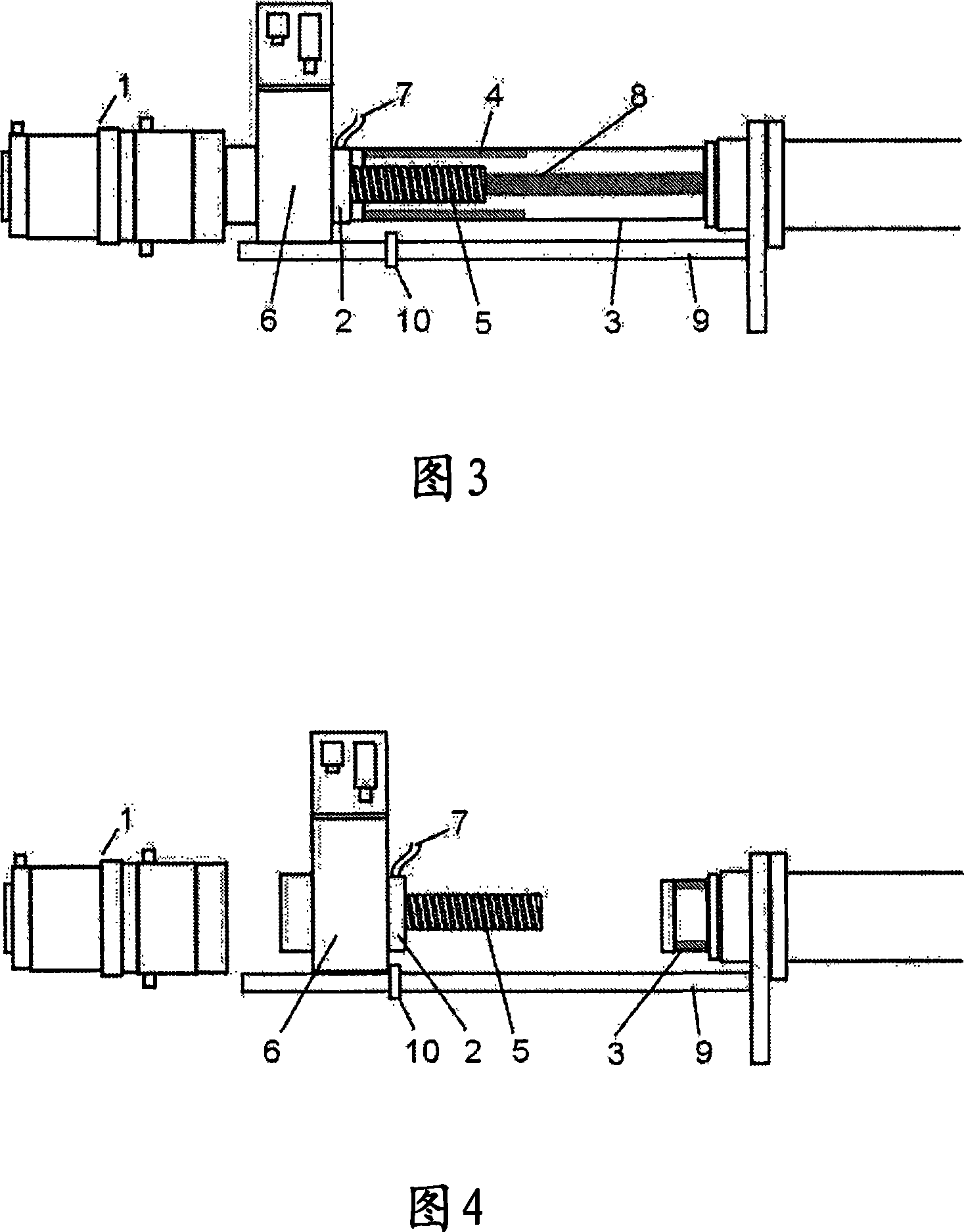

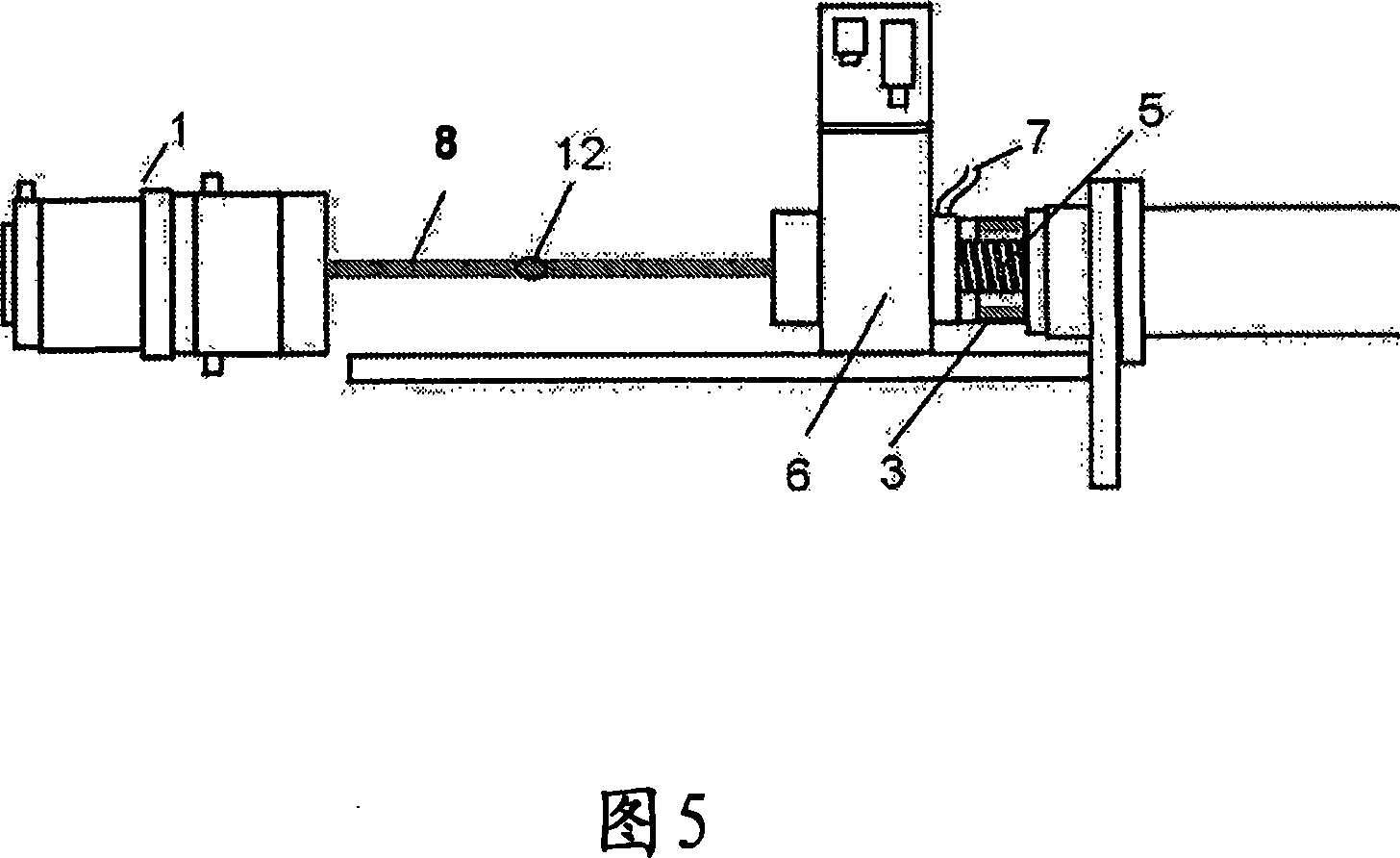

[0019] Figure 1 is a schematic view of an embodiment of the invention when the cable gland is closed during production. In FIG. 1 , an extrusion head 1 is represented for a production line of electrical cables 8 comprising electrical conductors, and one to three layers comprising insulating layers surrounding the electrical conductors. In the production of cables, the layers are extruded over the electrical conductor, which may be copper, aluminum or any other metal suitable for the purpose. After such extrusion, the layers must be crosslinked in order to provide the insulating layer with the desired properties. For the crosslinking reaction, the layers must be heated to a predetermined temperature. In the present invention, the heating of the layer is achieved at least partly by inductively heating the electrical conductor.

[0020] As shown in Figure 1, the device of the invention comprises a coil 5 as induction means for generating a magnetic field. The coil 5 is mounted...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com