Locking assembly, embedded cooktop and installation method

An installation method and embedded technology, applied in the field of cookers, can solve the problems of shielding and covering the reserved holes, the cooker cannot be embedded normally, and it is difficult to realize convenient locking and fitting, etc., so as to achieve the effect of avoiding exposure.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0040] The present invention will be further described below in conjunction with the accompanying drawings and specific embodiments.

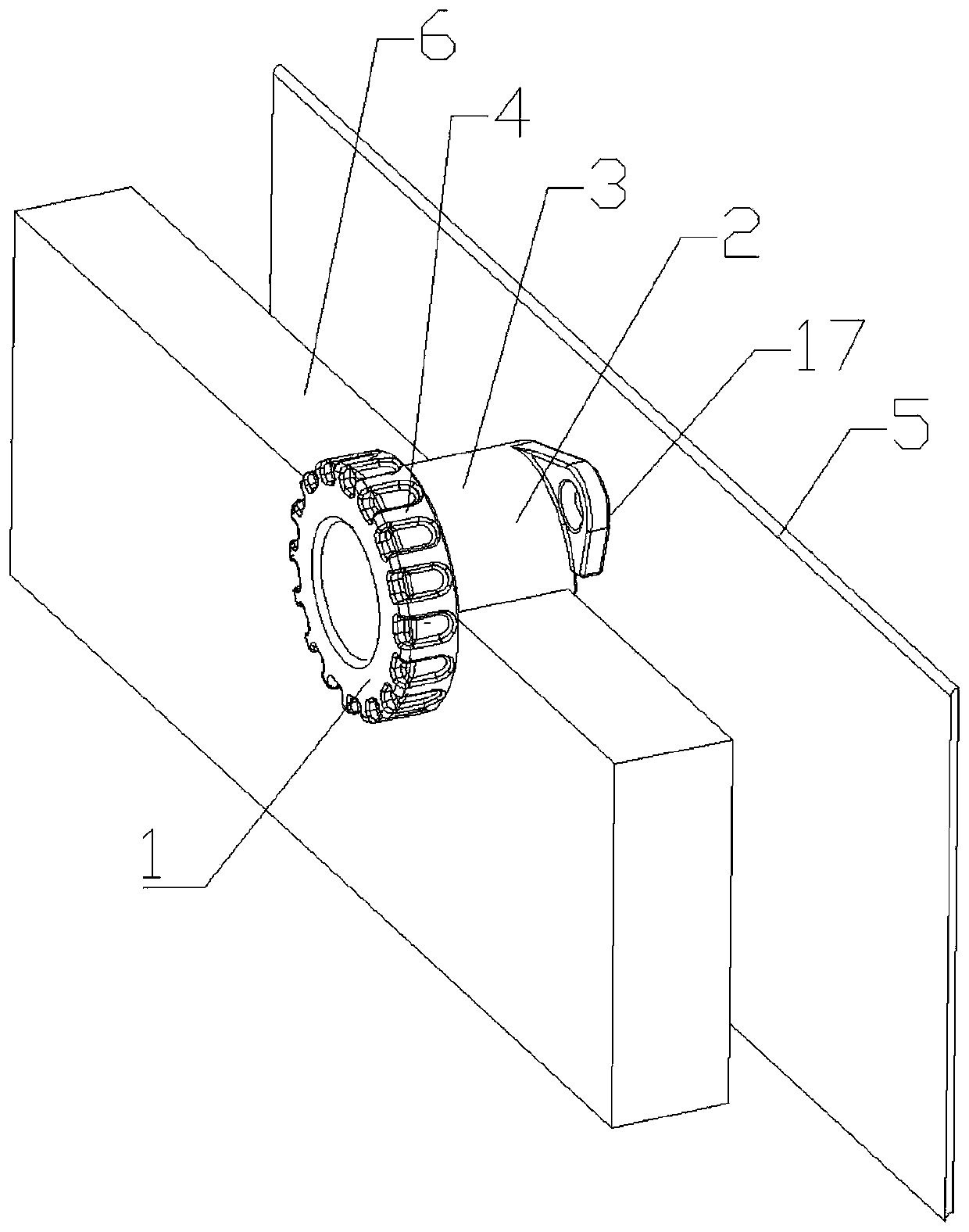

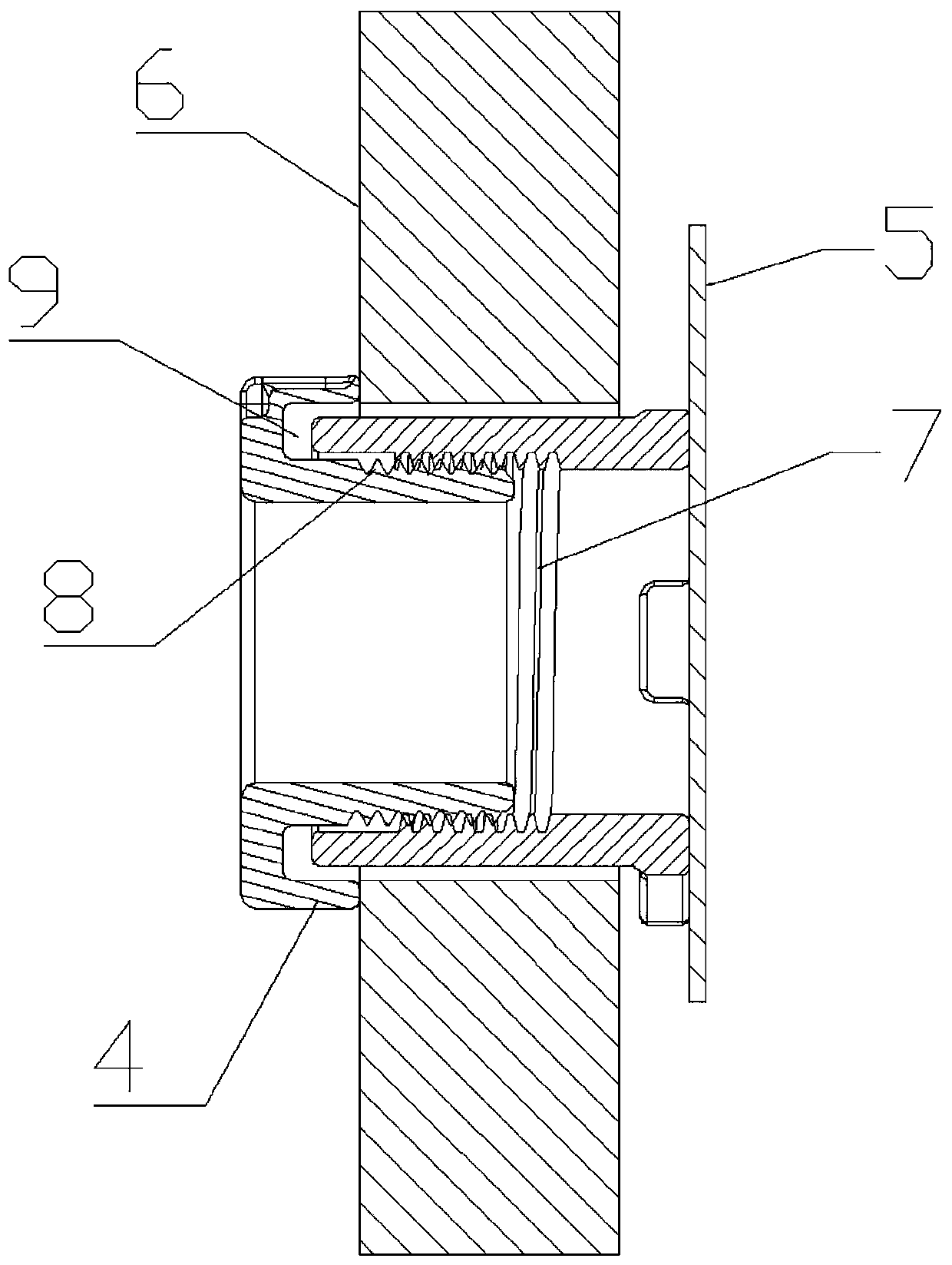

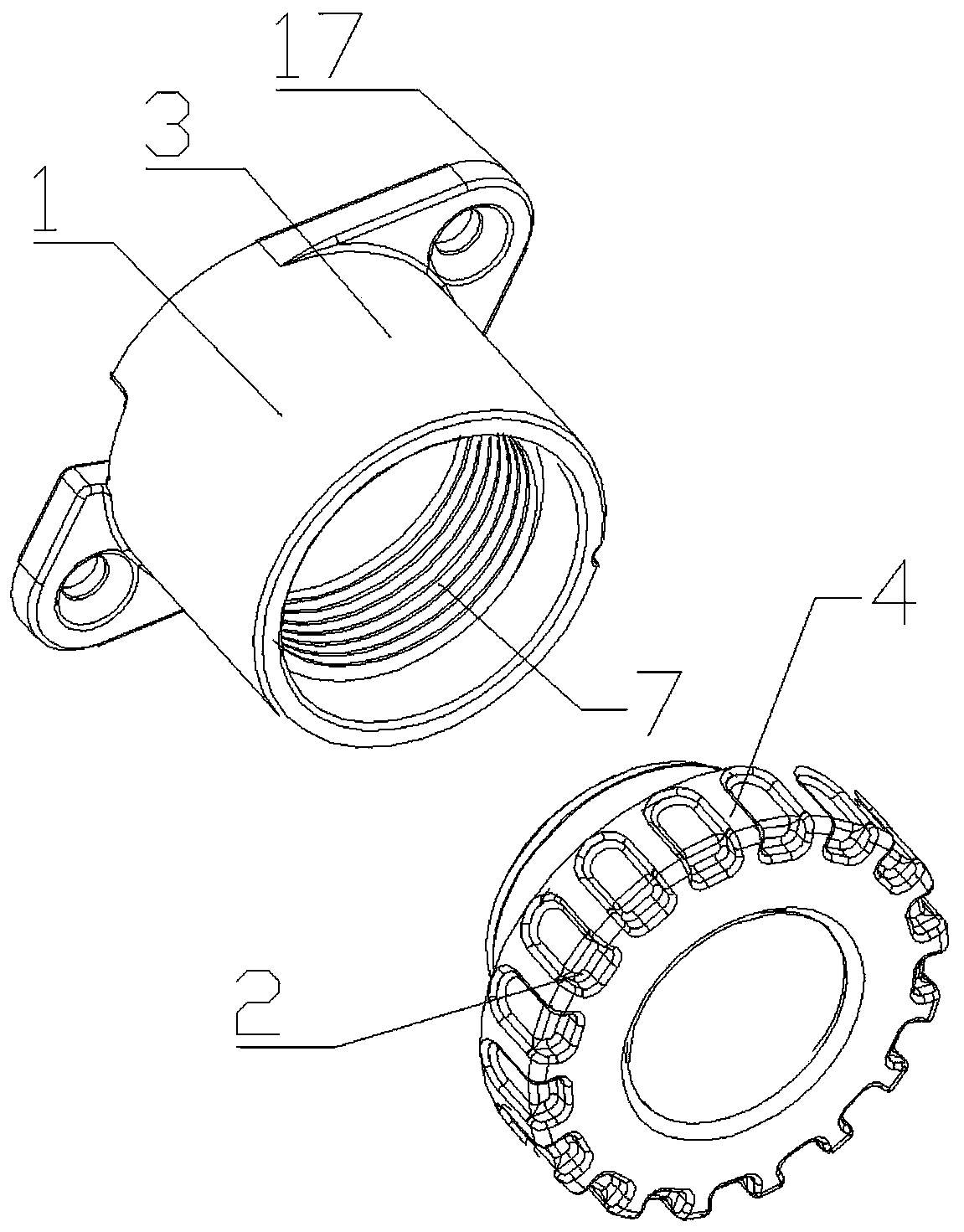

[0041] in figure 1 It is a structural schematic diagram of a locking assembly in use according to the present invention (parts of the second carrier have been removed to facilitate the display of other components). figure 2 It is a schematic cross-sectional structural diagram of a locking assembly in use according to the present invention. image 3 It is a schematic diagram of an exploded structure in a first orientation of a locking assembly of the present invention. Figure 4 It is a schematic diagram of an exploded structure in a second orientation of a locking assembly of the present invention. Figure 5 It is a structural schematic diagram of the first orientation of the built-in cooker with the locking assembly applied in the present invention (the part of the front operation panel has been removed to facilitate the display of other co...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com