Air-lift reverse circulation device for cast-in-situ bored piles

A technology of gas lift reverse circulation and bored cast-in-situ piles, which is applied to sheet pile walls, buildings, and foundation structure engineering, can solve problems such as unsuitable use, inconvenient disassembly and assembly, and easy bending. The effect of control monitoring, ensuring safety, and facilitating pressure relief

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0049] A gas reverse circulation sediment removal method for a gas lift reverse circulation device for bored piles, comprising:

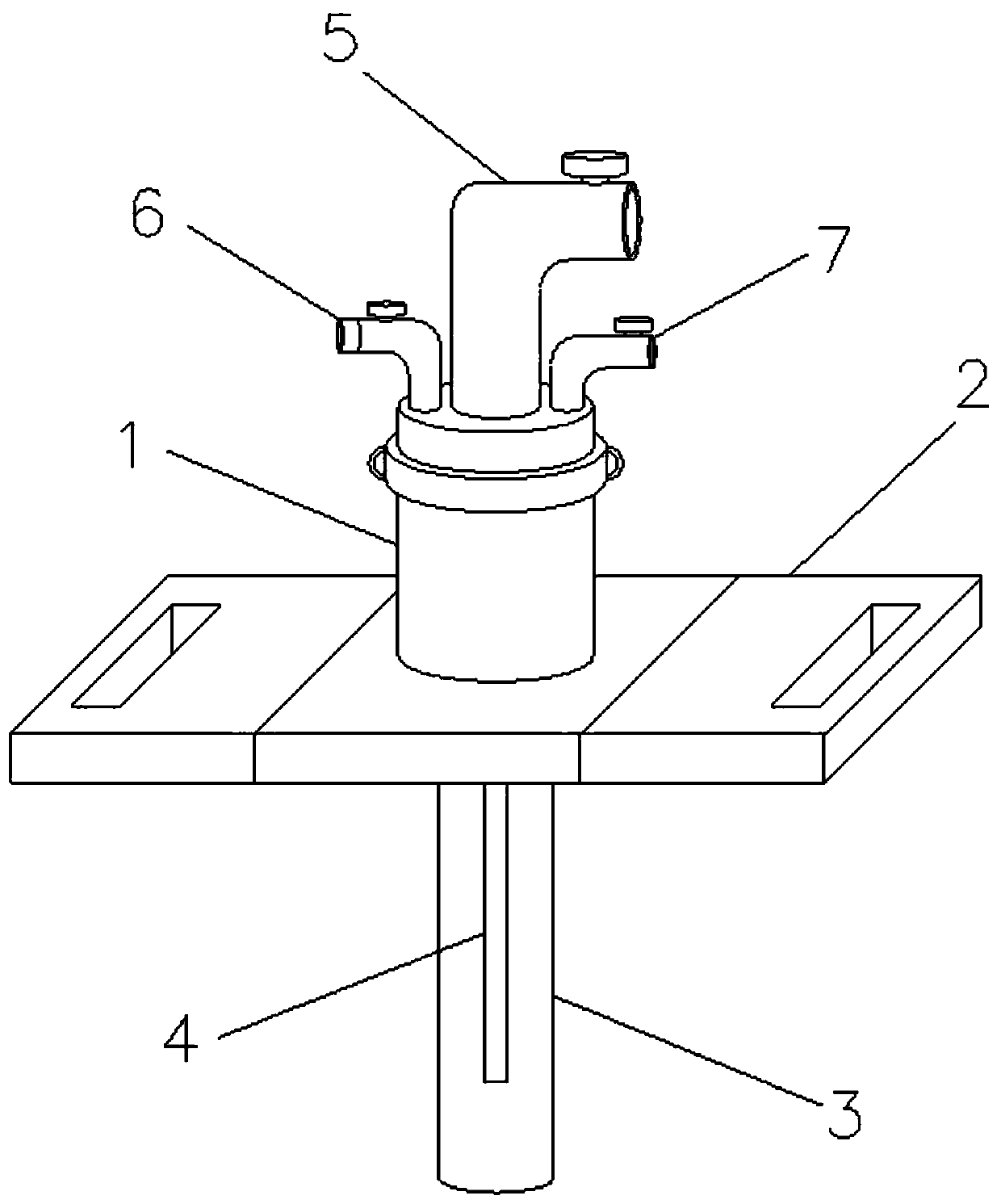

[0050] As mentioned above, the gas lift reverse circulation device for bored piles includes a base 1, a working platform 2, a conduit 3 and an air duct 4;

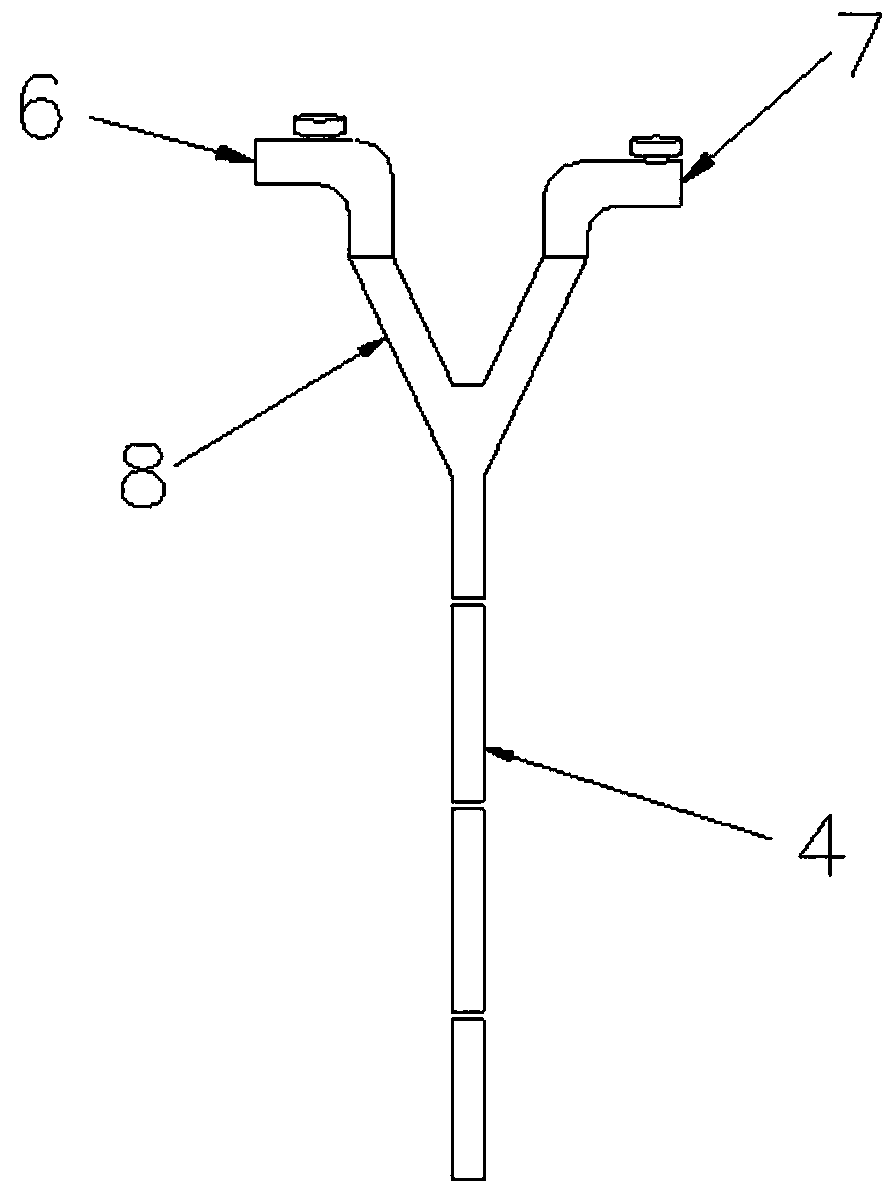

[0051] Pre-select the hollow steel pipe 401 of the required specification according to the needs to assemble the air pipe 4 and the conduit 3 for standby, and connect the air pipe 4 and the conduit 3 to the connecting seat at the lower end of the base 1;

[0052] That is, the hollow steel pipe 401 is firstly connected to each other through the external thread 402 at both ends and the hollow threaded sleeve 403, and assembled into the duct 3 and the air duct 4 of the required specification, and at the same time, the air duct 4 is connected to the air duct connecting seat 102 on the base 1 and Connect the conduit connecting seat 101. When connecting, first connect the air duct 4 to it, and then in...

Embodiment 2

[0060] The application of the gas reverse circulation sediment removal method for the gas lift reverse circulation device of the bored pile as described in Example 1 in the gas reverse circulation sediment removal.

[0061] During the sediment removal process at the bottom of the cast-in-place pile, referring to the operation steps of Example 1, the gas lift reverse circulation device of the bored cast-in-situ pile is used for sediment removal.

Embodiment 3

[0063] The application of the gas lift reverse circulation device for bored cast-in-place piles as described in Example 1 in gas reverse circulation mud exchange.

[0064] During the mud exchange process at the bottom of the cast-in-place pile, referring to the operation steps of Example 1, the gas-lift reverse circulation device of the bored cast-in-situ pile is used for mud exchange.

[0065] The gas lift reverse circulation device for bored piles of the present invention, the base is detachably installed on the working platform, the lower end of the base is detachably connected with the conduit and the air pipe, and the upper end of the base is installed with an air inlet port and a pressure monitoring port It is connected with the slag discharge interface and connected with the air pipe and conduit through the channel pipe. Firstly, the steel hollow round pipe is used as the air pipe and conduit, and is connected by a combination of thread and hollow thread sleeve to avoid ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com