Method for predicting vertical bearing capacity of vertical reinforcement of karst soil cavity

A bearing capacity prediction and reinforcement technology, which is applied in the field foundation soil survey, foundation structure test, construction, etc., to achieve the effect of strong flow, simple structure and reliable results.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0028] The present invention will be described in further detail below in combination with specific embodiments.

[0029] A method for predicting the vertical bearing capacity of a vertical reinforcement of a karst soil cave according to the present invention comprises the following steps:

[0030] Step S1: Determine the geometric size and covering soil depth z of the karst soil cave, determine the geometric dimensions of the karst soil cave, including the length L, width W, and height H of the karst soil cave, and further determine the distance from the top surface of the karst soil cave to the ground The covering depth z.

[0031] Step S2: Determine the number n and depth L of grouting holes in karst soil caverns according to construction conditions and design conditions 0 and diameter d.

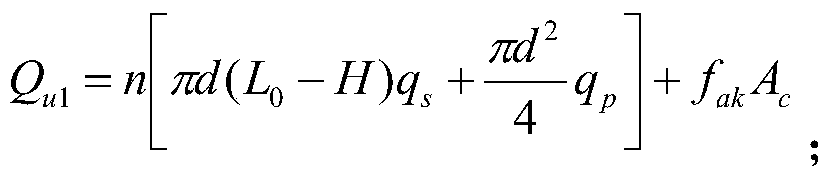

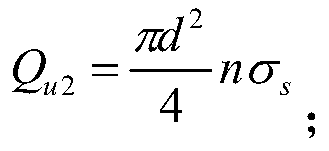

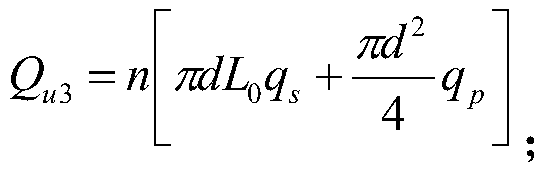

[0032] Step S3: Determine the compressive strength σ of the vertical reinforcement s , Ultimate side friction resistance q s and the limit end resistance q p ;

[0033] Take a certa...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com