Warp knitting machine

A warp knitting machine and frame technology, applied in the field of warp knitting machines, can solve the problems of unfavorable production costs, late maintenance, complex structure, large volume, etc., and achieve the effects of simple structure, reduced volume and floor space, and reduced production costs

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0037] Below in conjunction with embodiment the present invention is described in further detail.

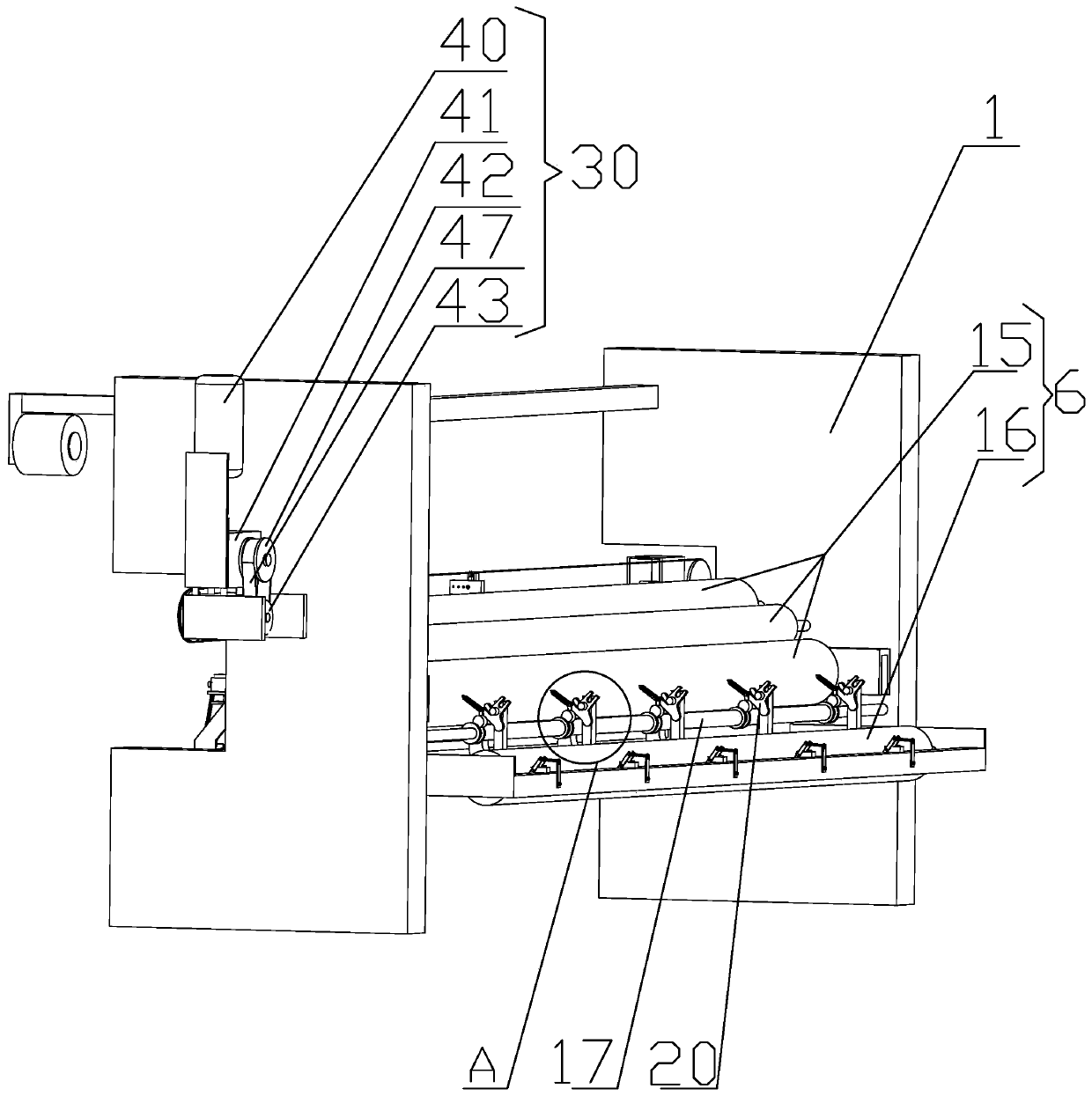

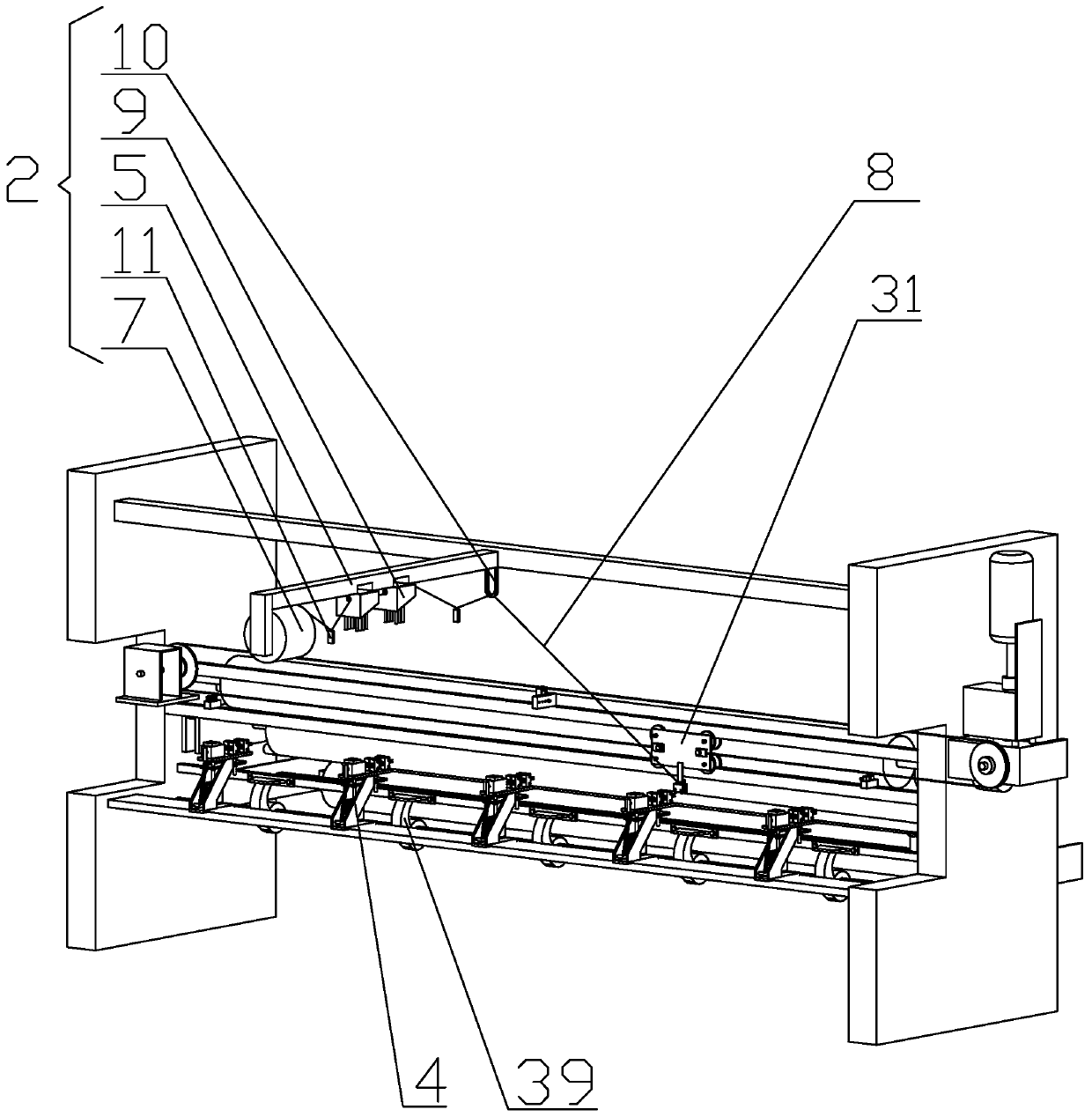

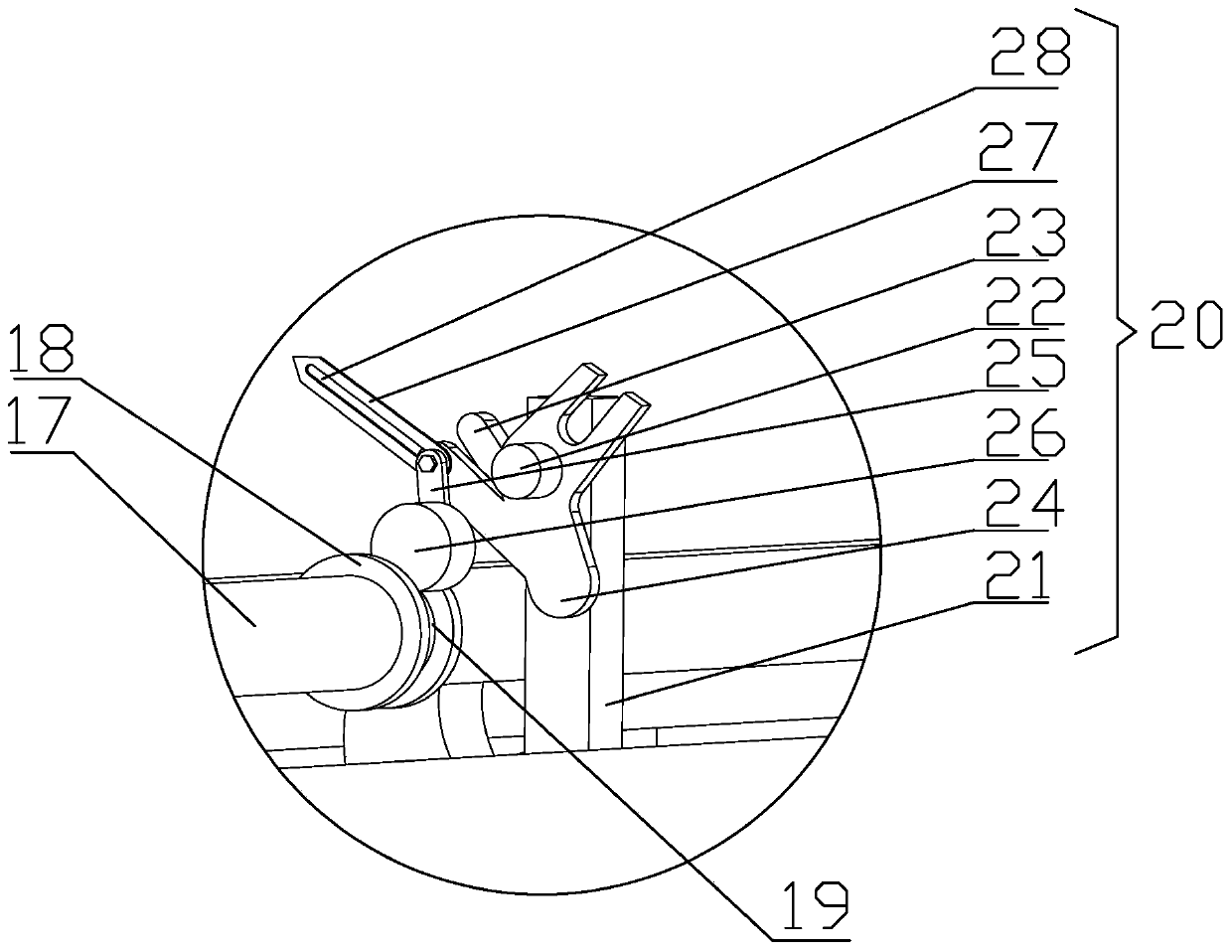

[0038] The present invention proposes a warp knitting machine, such as Figures 1 to 15 Shown, comprise frame 1, be connected with wire supply mechanism 2, wire delivery mechanism 3, mechanical arm 4, weaving mechanism and take-up mechanism 6 on frame 1, described wire delivery mechanism 3 will spin on the wire supply mechanism 2 The thread 8 is pulled out and delivered to the top of the weaving mechanism, and the mechanical arm 4 presses the drawn spinning thread 8 into the weaving mechanism for weaving, and is output by the take-up mechanism 6; the take-up mechanism 6 and the weaving mechanism are prior art warp knitting Common mechanism in the machine, wherein, the thread feeding mechanism of the present embodiment only provides the spinning thread that is arranged horizontally, and the vertical spinning thread providing device in the knitting mechanism is the same as the pri...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com