Carrier tape head end shifting and positioning mechanism for carrier tape automatic winding and collecting system

A technology of positioning mechanism and winding mechanism, which is applied in the direction of winding strips, thin material processing, transportation and packaging, etc., which can solve the problems that the carrier tape cannot be reliably wound, and the head end of the carrier tape cannot be effectively positioned, so as to achieve reliable positioning , to avoid loose effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

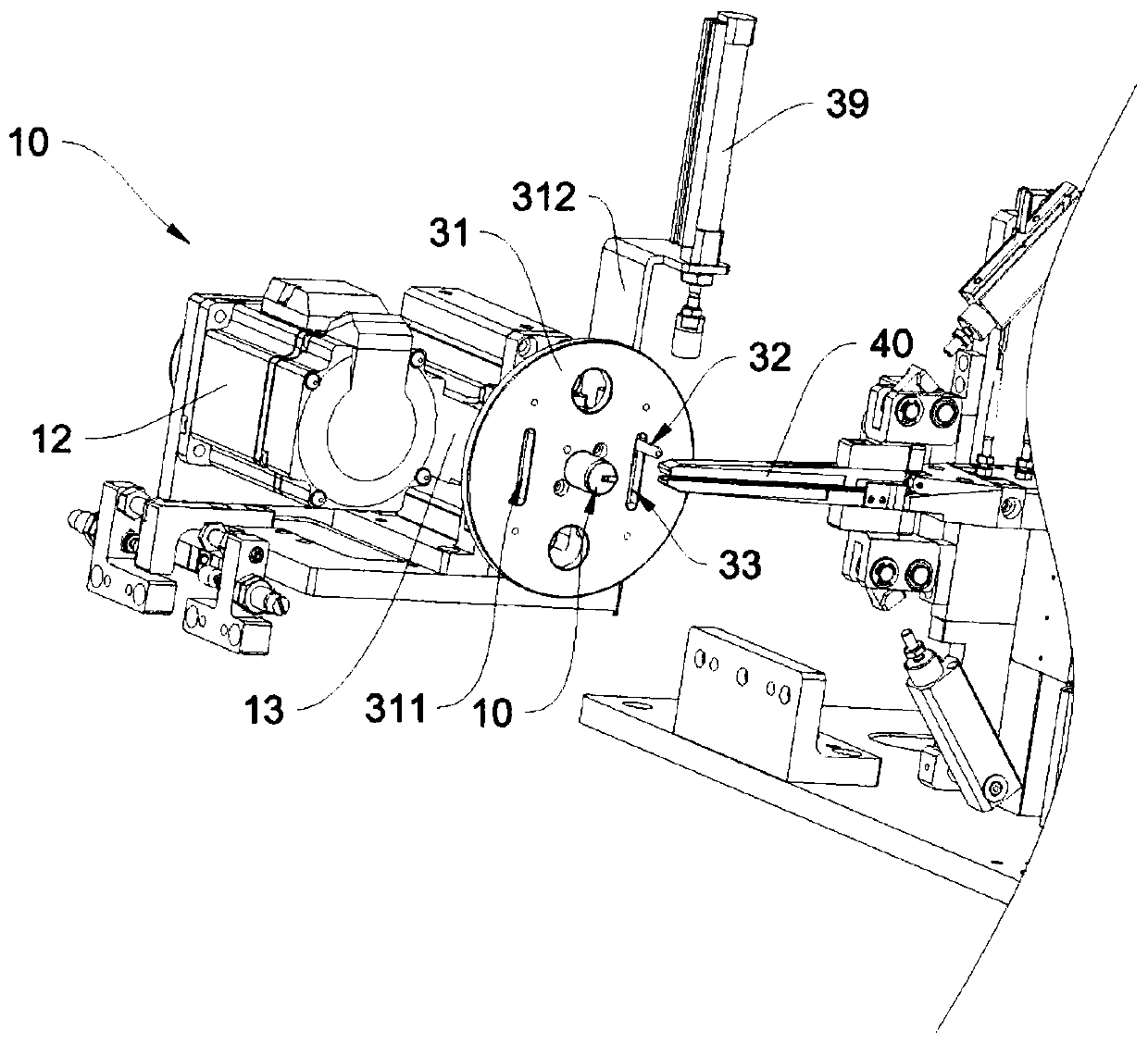

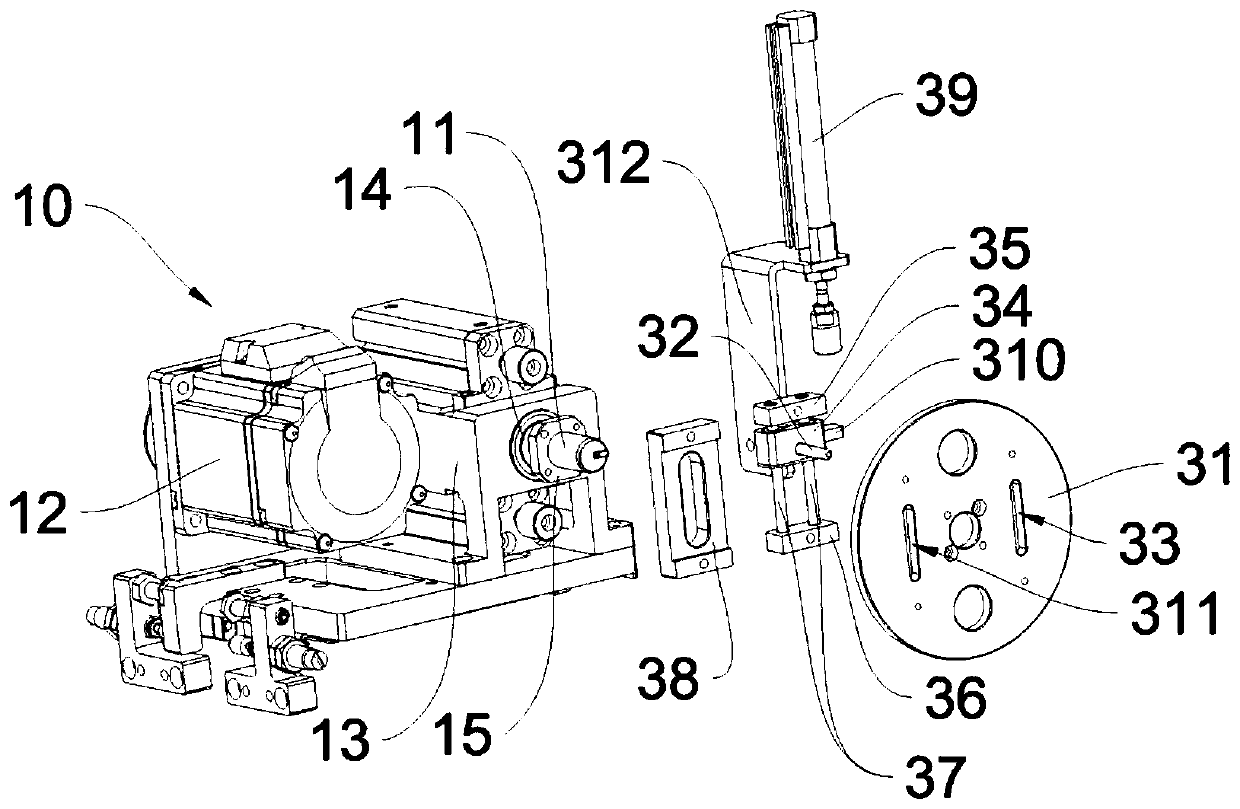

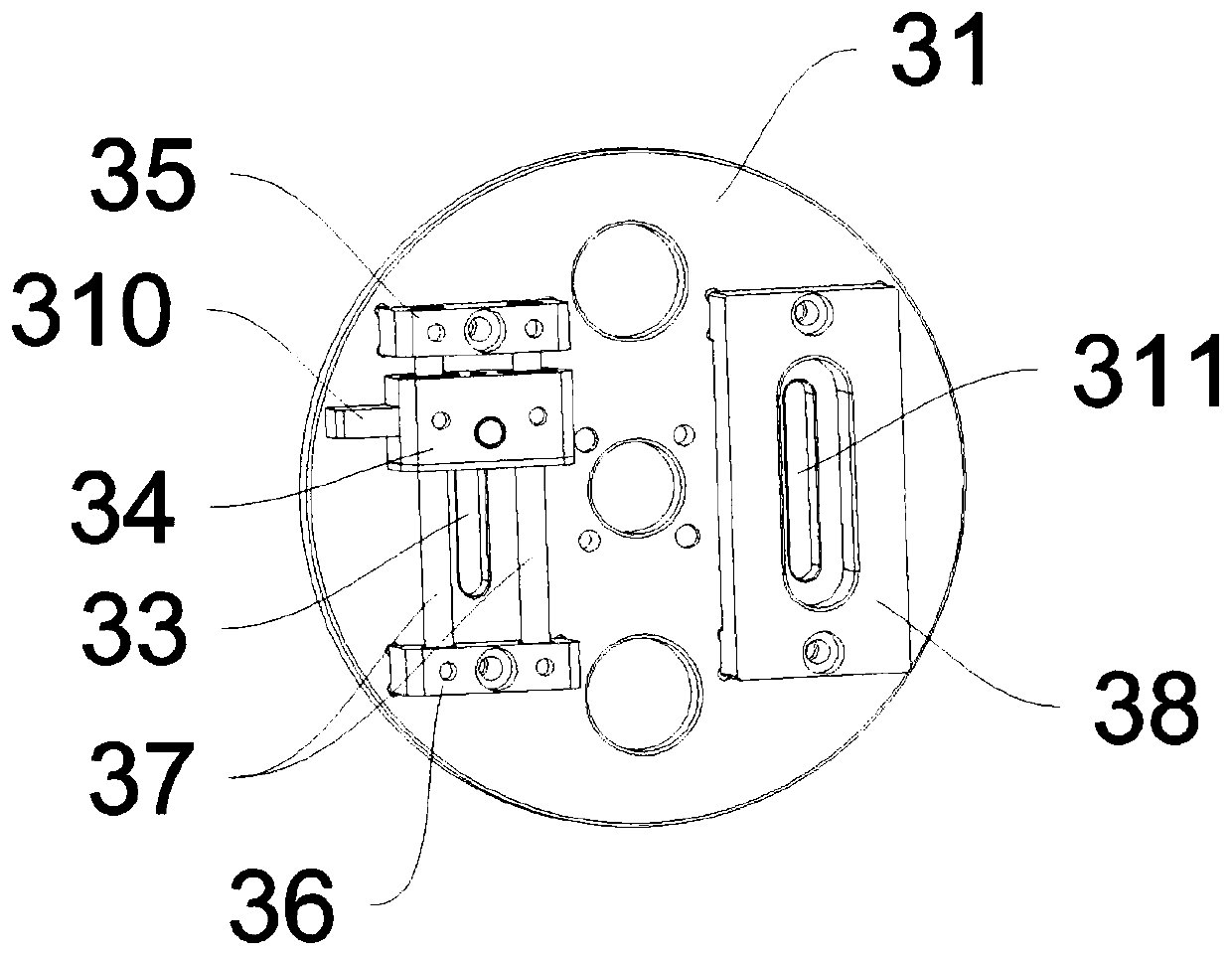

[0017] See figure 1 , the present invention is used for the carrier tape head end toggle positioning mechanism of the carrier tape automatic winding system, the carrier tape automatic winding system includes a winding mechanism 10, and the winding mechanism 10 includes a winding shaft 11 and a winding motor 12, The reel 20 is detachably mounted on the reel 11 through its central axis hole 21, and the reel 12 can drive the reel 11 to drive the reel 20 to rotate. In this embodiment, the reel 12 drives the reel through a synchronous sprocket 11 rotation; it also includes a toggle positioning base plate 31, a dial needle 32 and a toggle drive assembly, the winding shaft 11 runs through the toggle positioning base plate 31 from the back to the front, and the reel 20 for winding the carrier tape passes through its central shaft hole 21 is installed on the protruding end of the rewinding shaft 11 protruding on the dial positioning base plate 31, and a vertical dialing groove 33 is p...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com