Electromagnetic induction heating plate for tire vulcanizer

A tire vulcanization and heating plate technology, applied in tires, applications, household appliances, etc., can solve problems such as effective values of electromagnetic parameters affecting system reliability, waste of coil materials, etc., to reduce combustion energy, save materials, and increase effective area. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

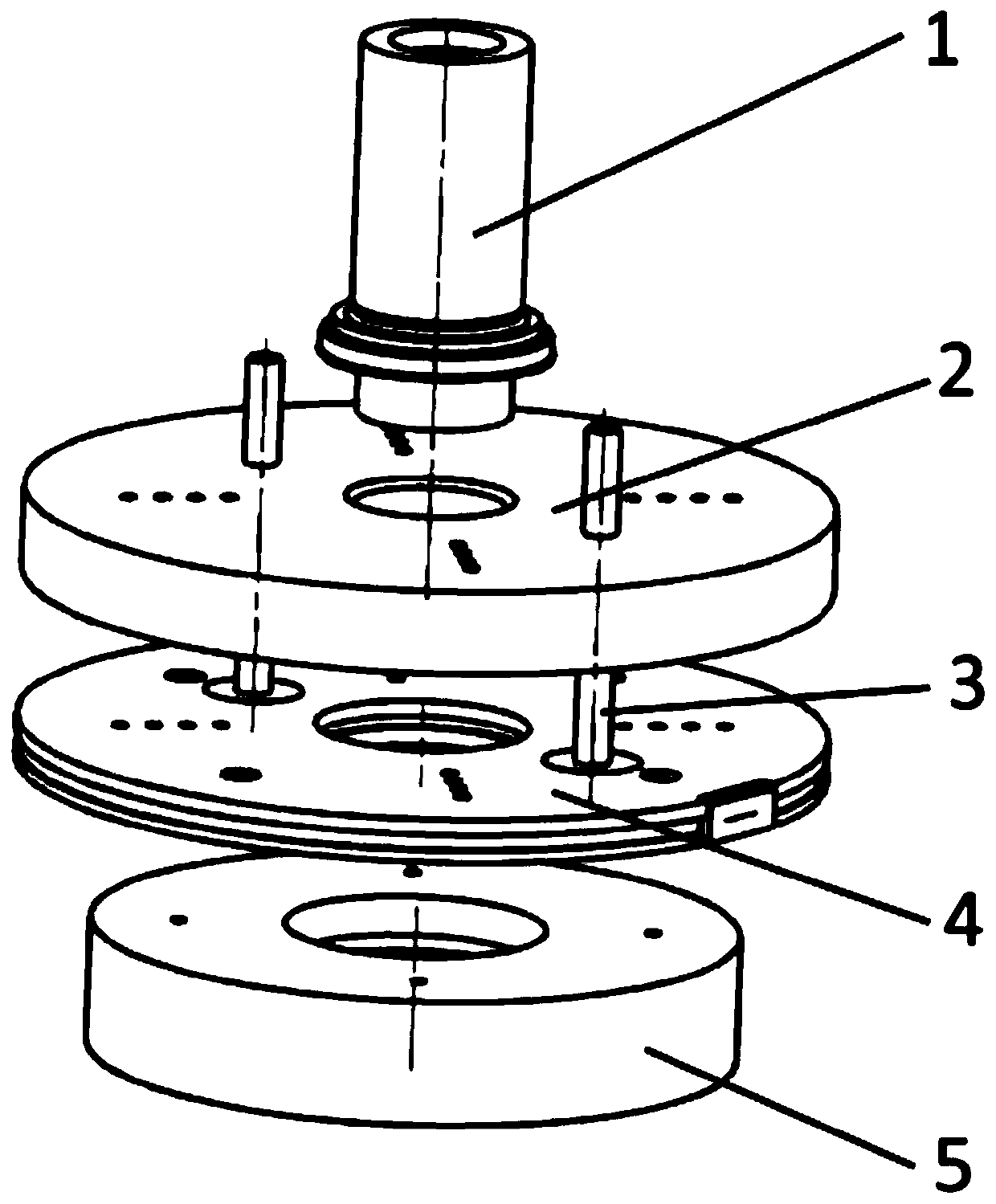

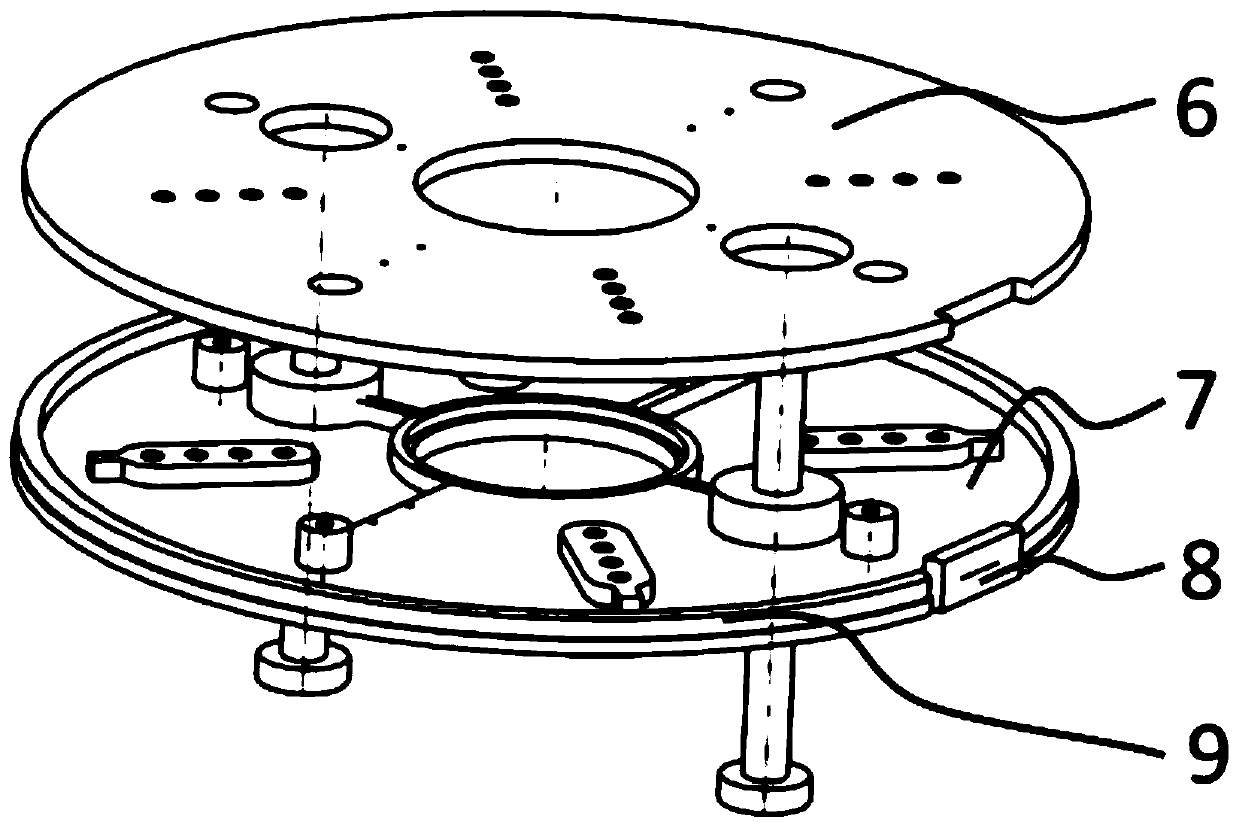

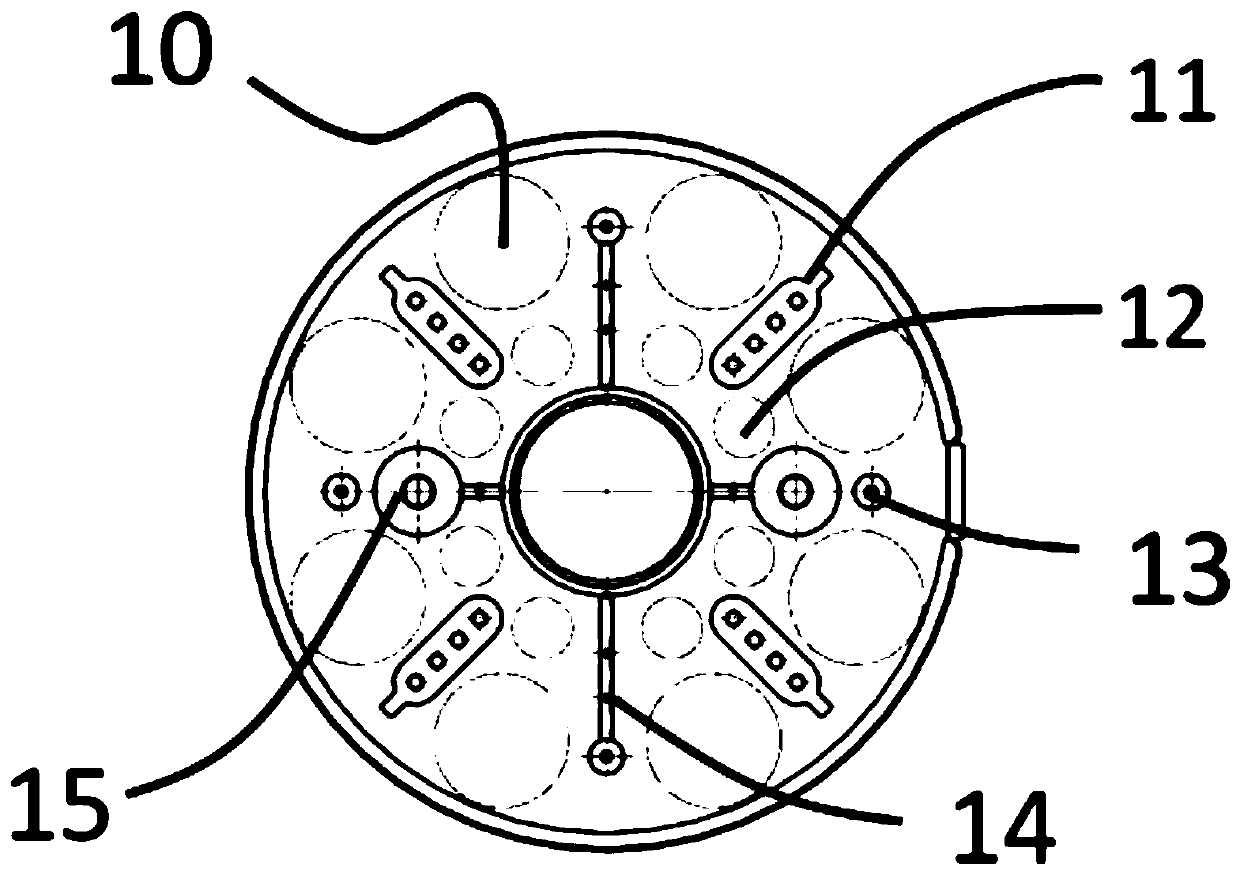

[0030] see Figure 1-7 According to an embodiment of the present invention, an electromagnetic induction heating plate for a tire vulcanizing machine includes a lifting column 1, an upper mold seat 2, a guide column 3, a heating plate 4, and an upper mold 5 for a vulcanizing machine tire. The upper mold seat 2 is arranged on At the bottom of the guide column 3, the heating plate 4 is installed between the upper mold base 2 and the upper mold 5 of the vulcanizer tire, and the heating plate 4 is composed of a heating plate back plate 6, a heating plate panel 7, a wire outlet interface 8 and an edge positioning ring 9 Composition, the heating plate panel 7 is located at the bottom of the heating plate back plate 6 and the heating plate panel 7 is provided with a first induction coil plate 10, a through-hole seat 11, a second induction coil plate 12, an internal thread column 13, and a back plate fixing hole 14 and a fixed ring 15, wherein the through hole seat 11 is provided with...

Embodiment 2

[0033] see Figure 1-4 and Figure 7-8 According to an embodiment of the present invention, an electromagnetic induction heating plate for a tire vulcanizing machine includes a lifting column 1, an upper mold seat 2, a guide column 3, a heating plate 4, and an upper mold 5 for a vulcanizing machine tire. The upper mold seat 2 is arranged on At the bottom of the guide column 3, the heating plate 4 is installed between the upper mold base 2 and the upper mold 5 of the vulcanizer tire, and the heating plate 4 is composed of a heating plate back plate 6, a heating plate panel 7, a wire outlet interface 8 and an edge positioning ring 9 Composition, the heating plate panel 7 is located at the bottom of the heating plate back plate 6 and the heating plate panel 7 is provided with a first induction coil plate 10, a through-hole seat 11, a second induction coil plate 12, an internal thread column 13, and a back plate fixing hole 14 and a fixed ring 15, wherein the through hole seat 11...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com