Prefabricated wallboard external hanging rack prefabricated hole and hoisting device

A technology of prefabricating wall panels and reserving holes, which is used in unloading devices, manufacturing tools, transportation and packaging, etc., can solve the problems of large workload, high cost, and large amount of embedded parts for cleaning PVC pipes.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

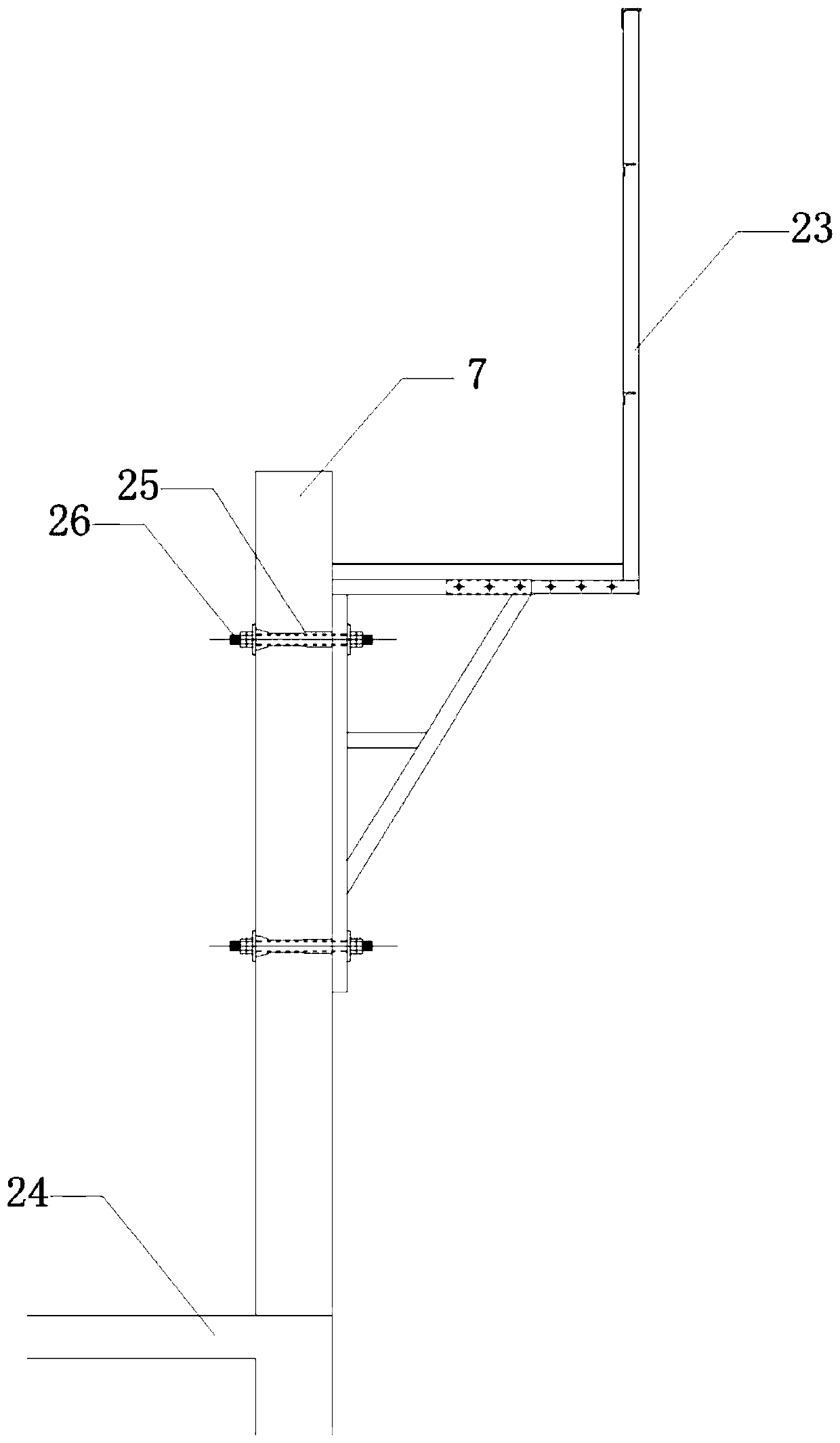

[0030] See attached picture.

[0031] A prefabricated wallboard hanger reserved hole and a device for hoisting, including a base 4 fixed on the mold table 6, and a positioning nut 3 welded and fixed on the mold table 6, used for piercing holes formed by the prefabricated wallboard 7 Pipe 1, screw rod 2 for installation and disassembly, plastic cover 5 to prevent concrete from entering, and hoisting piece 8 for horizontal hoisting; pipe 1 includes upper casing 12, lower casing 11, internal welding gasket 13 and screw Cap 9 is formed, and the screw rod 2 that installs and disassembles is made up of screw rod nut 15 and small screw mandrel 16 welding, and horizontal hoisting part 8 is formed by steel plate 22 welding big screw mandrel 21.

[0032] The gasket 13 on the pipe 1 is formed by laser cutting of 10mm thick steel plate with an outer circle of φ41mm and an inner circle of φ20mm. The nut 9 adopts an M16 nut, and the upper casing adopts a circular tube with a length of φ48mm...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com