Multifunctional window frame cutting and polishing device

A cutting and grinding, multi-functional technology, applied to other manufacturing equipment/tools, manufacturing tools, etc., can solve problems such as unfavorable alignment, generation of a lot of metal shavings, and large occupied area

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

specific Embodiment approach 1

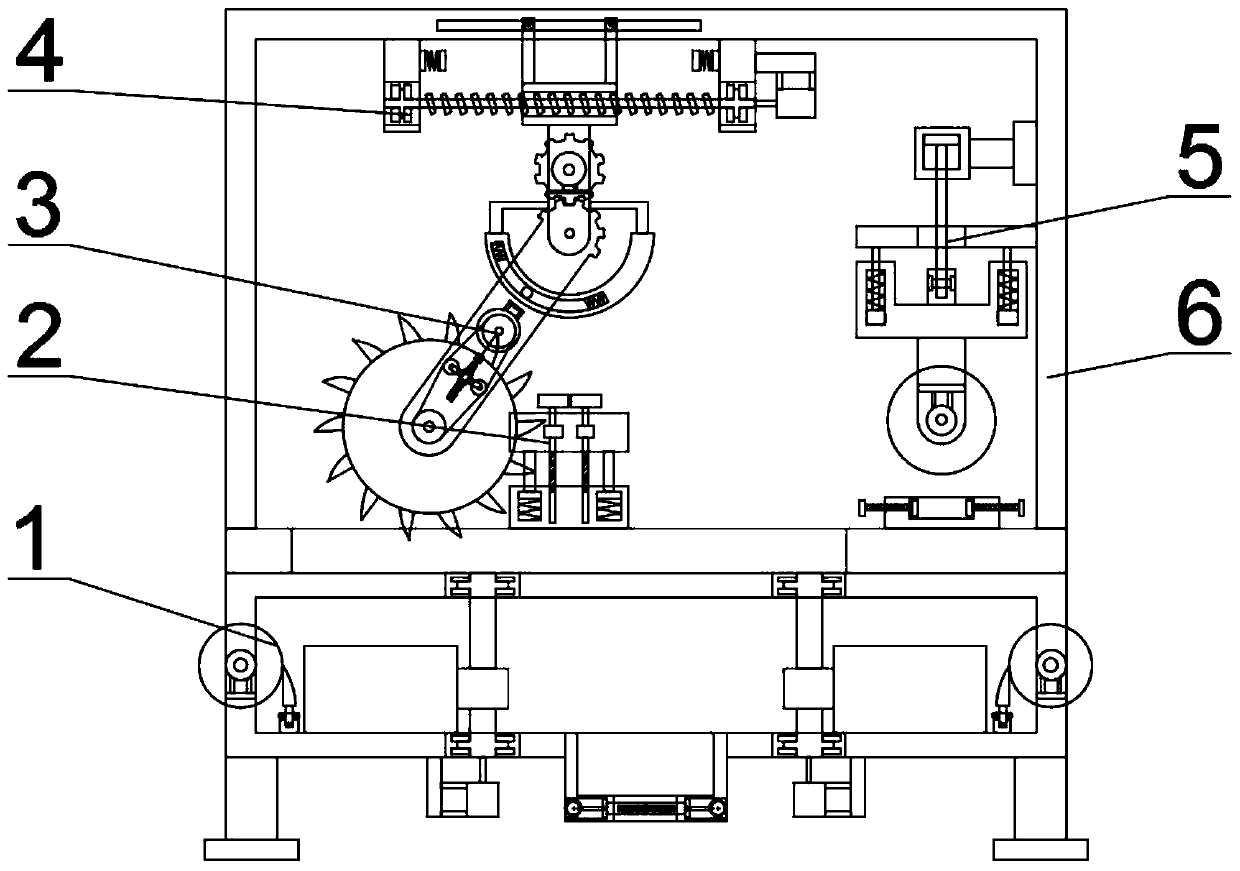

[0044] Combine below figure 1 , figure 2 , image 3 , Figure 4 , Figure 5 , Figure 6 , Figure 7 , Figure 8 , Figure 9 , Figure 10 , Figure 11 , Figure 12 , Figure 13 , Figure 14 , Figure 15 , Figure 16 , Figure 17 To illustrate this embodiment, the present invention relates to a cutting and polishing device, more specifically, a multifunctional window frame cutting and polishing device, which includes an iron filings collection mechanism 1, a clamping mechanism 2, a cutting actuator 3, and a cutting and moving mechanism 4 , grinding mechanism 5, body frame mechanism 6, the device can cut, the device can tension the belt, the device can change the cutting position, the device can change the cutting angle, the device can clamp the door and window frame, the device can grind, and the device can recycle waste .

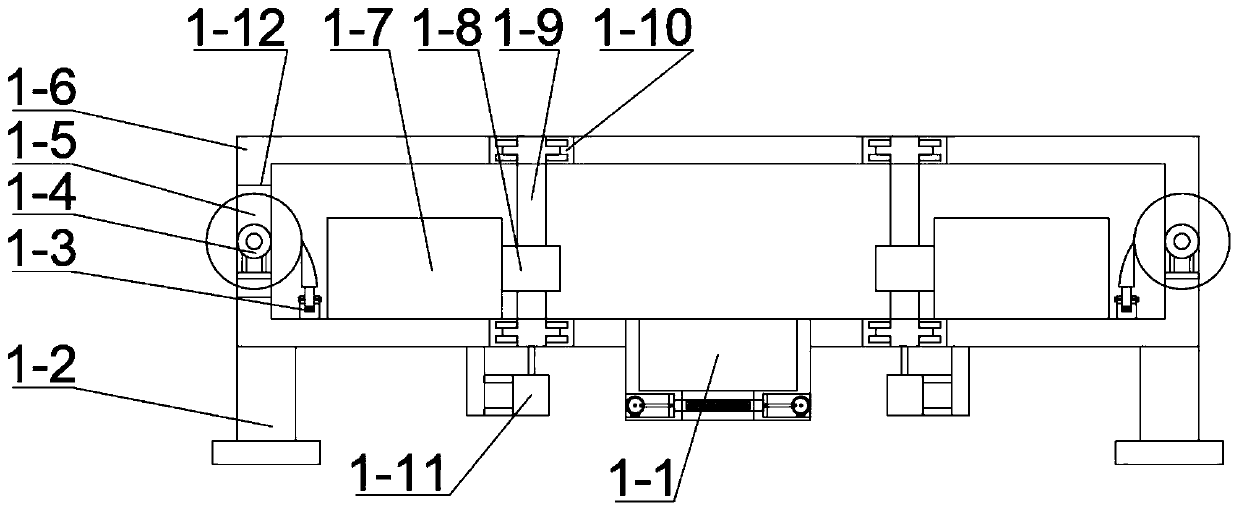

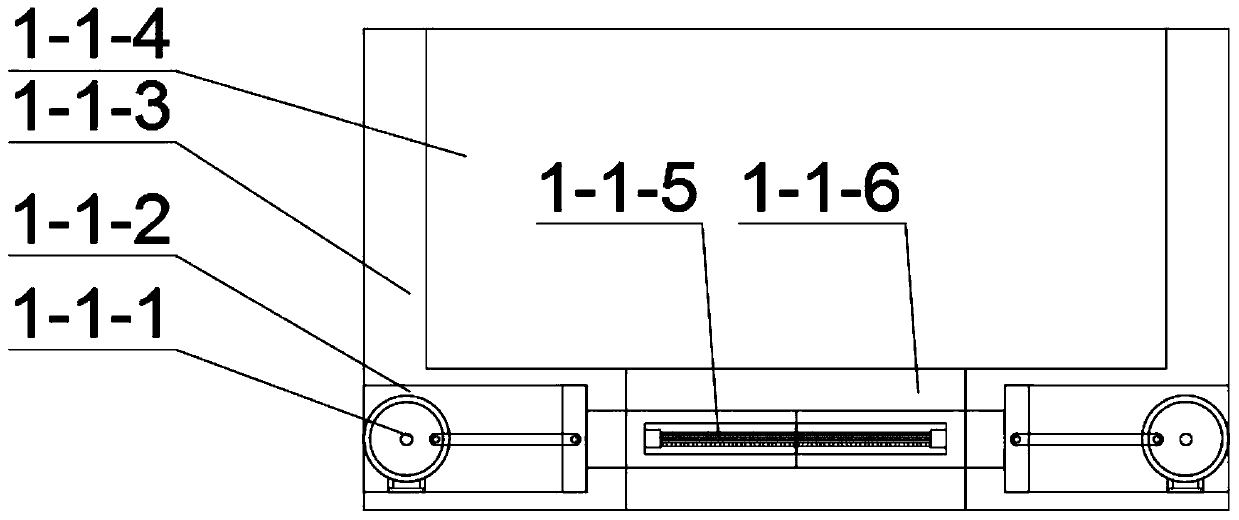

[0045] Iron filings collection mechanism 1 includes collection box mechanism 1-1, outrigger 1-2, iron filings scraper mechanism 1-3, magnet...

specific Embodiment approach 2

[0061] Combine below figure 1 , figure 2 , image 3 , Figure 4 , Figure 5 , Figure 6 , Figure 7 , Figure 8 , Figure 9 , Figure 10 , Figure 11 , Figure 12 , Figure 13 , Figure 14 , Figure 15 , Figure 16 , Figure 17 This embodiment will be described. This embodiment will further describe the first embodiment, and the number of the magnetic wheels 1-5 is two.

specific Embodiment approach 3

[0063] Combine below figure 1 , figure 2 , image 3 , Figure 4 , Figure 5 , Figure 6 , Figure 7 , Figure 8 , Figure 9 , Figure 10 , Figure 11 , Figure 12 , Figure 13 , Figure 14 , Figure 15 , Figure 16 , Figure 17 This embodiment will be described. This embodiment will further describe the first embodiment. The material of the cutting blade 3-1-1 is stainless steel.

[0064] The device is capable of cutting, first place the window frame to be cut between the clamping lower seat 2-2 and the clamping upper seat 2-10, and then turn the screw 2-7, the screw 2-7 will pass through the screw hole 2 The cooperation of -1 drives the clamping upper seat 2-10 to move downward, and the downward movement of the clamping upper seat 2-10 will clamp the window frame, and then run the cutting motor 3-5, which will drive the cutting motor wheel 3- 4 rotates, and the cutting motor wheel 3-4 rotates and will drive the belt 3-2 to move, and the movement of the belt 3...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com