Online predicting method for silicon content of blast furnace molten iron

A technology of blast furnace hot metal and prediction method, which is applied in molecular entity identification, chemical machine learning, chemical data mining, etc., can solve the problems of not considering the highly nonlinear and time-varying characteristics of the blast furnace system, so as to avoid model stability and accuracy The influence of sex, fast training speed, and the effect of improving prediction accuracy

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0044] In order to make the technical problems, technical solutions and advantages to be solved by the present invention clearer, the following will describe in detail with reference to the drawings and specific embodiments (taking a domestic blast furnace as the research object).

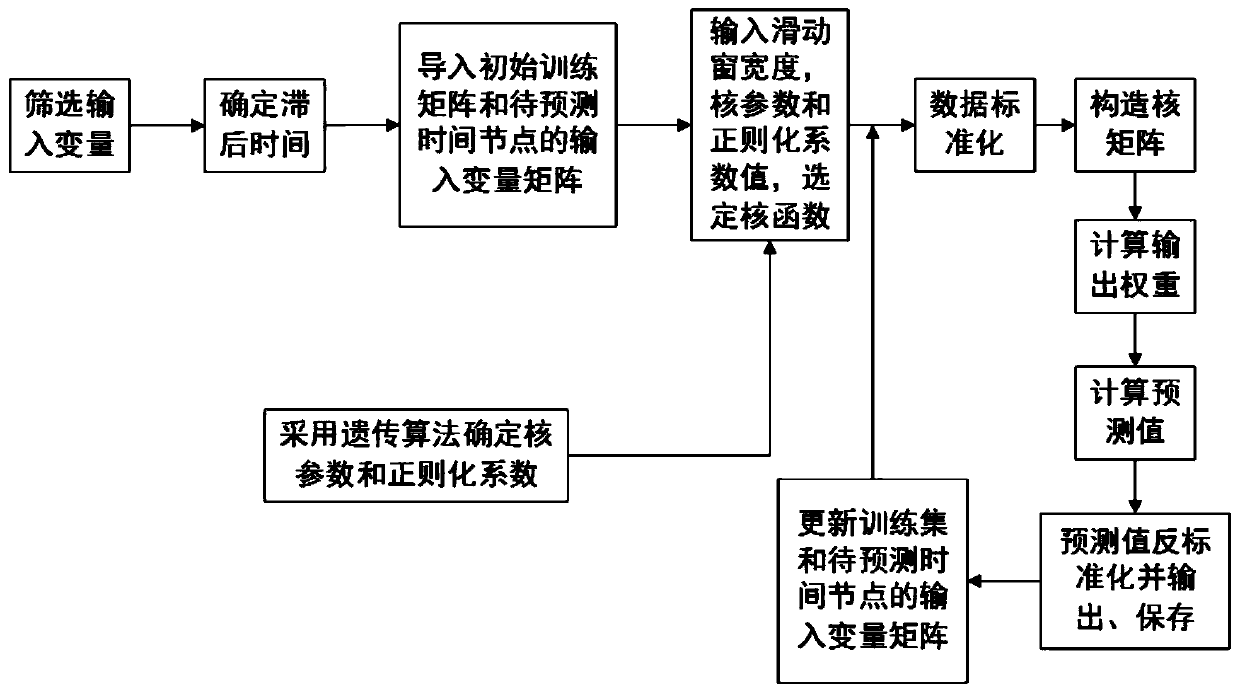

[0045] The invention provides an online method for predicting the silicon content of molten iron in a blast furnace. The implementation flow chart of the method is as follows figure 1 As shown, the main implementation steps and examples are as follows:

[0046] 1) According to the transmission mechanism of silicon in the blast furnace and the existing detection conditions of the blast furnace, determine the input variables of the model. Taking a large domestic blast furnace as an example, select: hourly material batch, total air volume, air temperature, air pressure, and coal injection volume 13 parameters, such as fuel ratio, total oxygen, gas permeability index, furnace wall temperature difference,...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com