Double-working-surface integrated bridge girder erection machine without front supporting legs

A bridge erecting machine and double-working technology, which is applied in the direction of erecting/assembling bridges, bridges, bridge construction, etc., can solve the problems of poor adaptability, reduced work efficiency, and many processes, so as to achieve high erection efficiency, improve operation efficiency, and improve adaptability sexual effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0028] In order to describe the present invention more specifically, the technical solutions of the present invention will be described in detail below in conjunction with the accompanying drawings and specific embodiments.

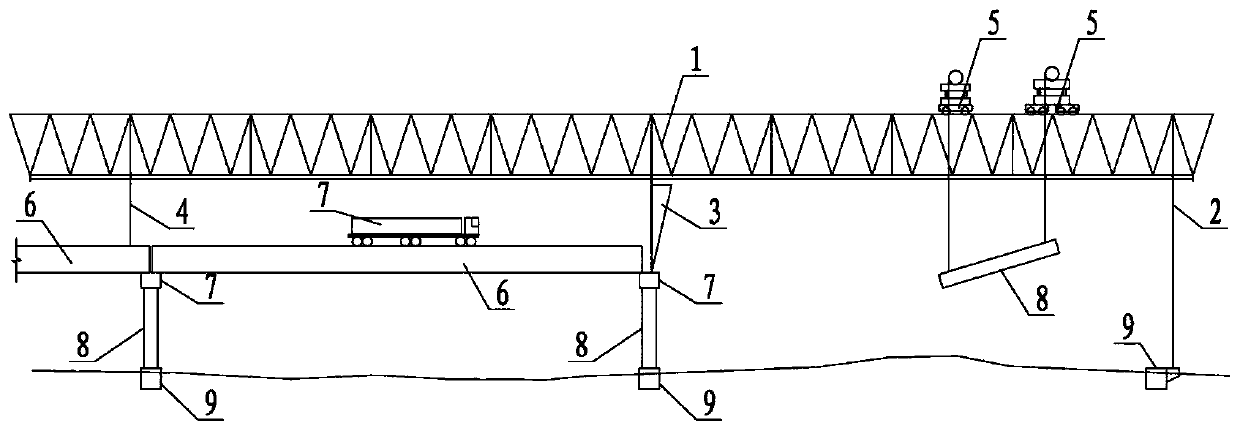

[0029] The present invention provides an integrated bridge-erecting machine with double working surfaces without front outriggers. The bridge-erecting machine itself is fully supported on the erected girder spans, so it is not affected by the undulating terrain and has strong adaptability. , The erection efficiency is high, and its structural layout is as follows image 3 , Figure 4 , Figure 5(a), Figure 5(b).

[0030] Such as image 3 As shown, the main basic components of this dual-face integrated bridge erecting machine without front outriggers mainly include: main truss 1, cable tower 2 and cable 3, front load-bearing outrigger 4, auxiliary outrigger 5, rear Bearing leg 6 and crane 11.

[0031] Such as Figure 4 As shown, the main truss 1 is a t...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com