A kind of double-hardness physical fitness test shoe rubber base material and preparation method thereof

A dual-hardness, rubber material technology, applied in shoe soles, footwear, clothing, etc., can solve the problems of uneven wear strength, unsatisfactory physical properties, deflection and deformation of shoes, and achieve suitable hardness differences and tight joints. , Lightweight sole effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0068] The dual hardness of the present embodiment tests the shoe rubber substrate, including high hardness rubber material and low hardness rubber material, low hardness rubber material has a hardness of 30A, and the hardness of high hardness rubber material is 50A;

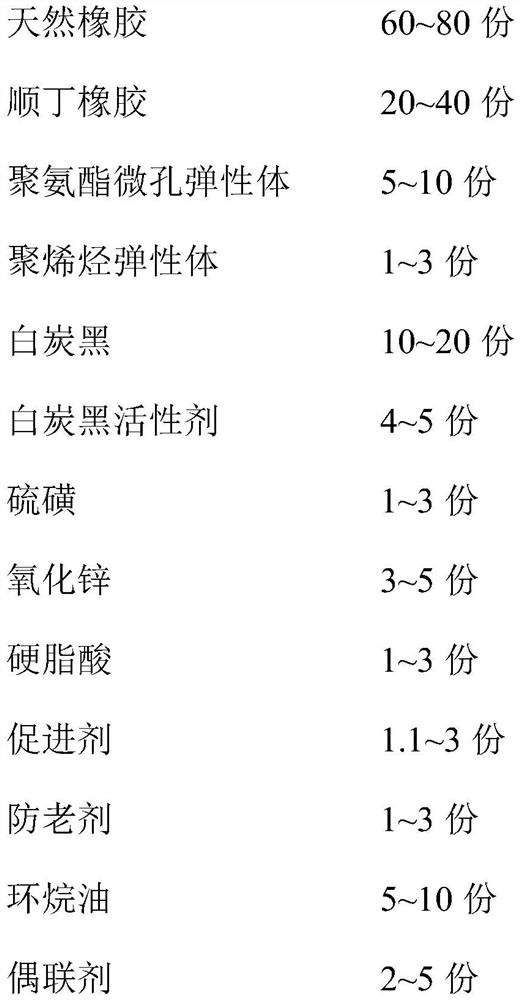

[0069] According to the weight, the low-hardness rubber material contains the following components:

[0070]

[0071] Among them, in low hardness rubber materials, the polyurethane microporous elastomer has a hardness of 40A, and the molded density of the polyurethane microporous elastomer is 0.4 g / m. 3 The accelerator consists of 1 part of the promoter DM and 1 part of the accelerator TMTM-80; the coupling agent consists of 2 parts of the A189 silane coupling agent and 1 part Si-69 silane coupling agent; anti-aging agent is BHT anti-aging agent, MB A mixture of protected agents, Vaseline and paraffin, and weight ratio of 0.5: 0.3: 1: 0.5.

[0072] The above-mentioned low-hardness rubber material has the prepara...

Embodiment 2

[0082] The double hardness body energy test the shoe rubber substrate, including a high hardness rubber material and a low hardness rubber material, the low hardness rubber material is 40A, and the hardness of the high hardness rubber material is 50A;

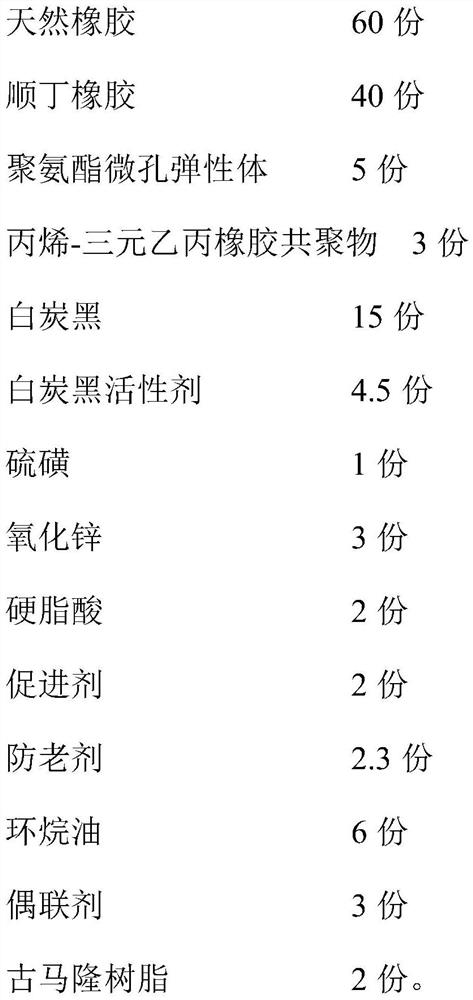

[0083] According to the weight, the low-hardness rubber material contains the following components:

[0084]

[0085] Among them, in the low-hardness rubber material, the hardness of the polyurethane microporous elastomer is 45a, and the molded density of the polyurethane microporous elastomer is 0.5 g / m. 3 The accelerator consists of 1 part of the promoter DM and 1 part of the accelerator TMTM-80; the coupling agent consists of 2 parts of the A189 silane coupling agent and 1 part Si-69 silane coupling agent; anti-aging agent is BHT anti-aging agent, MB A mixture of protected agents, Vaseline and paraffin, and weight ratio of 1: 0.3: 1: 0.5.

[0086] The above-mentioned low-hardness rubber material has the preparation method co...

Embodiment 3

[0096] The dual hardness body of the present embodiment test the shoe rubber substrate, including high hardness rubber material and low hardness rubber material, low hardness rubber material has a hardness of 35A, and the hardness of high hardness rubber material is 55A;

[0097] According to the weight, the low-hardness rubber material contains the following components:

[0098]

[0099] Among them, in low hardness rubber materials, the hardness of the polyurethane microporous elastomer is 46a, and the molded density of the polyurethane microporous elastomer is 0.6 g / m. 3 The promoter is composed of 1 part of the promoter DM and 1.4 parts accelerator TMTM-80; the coupling agent consists of 1.5 parts of a A189 silane coupling agent and 2 parts Si-69 silane coupling agent; the aging agent is BHT anti-aging agent, MB A mixture of antioxidants, Vaseline and paraffin, and a weight ratio of 0.8: 0.2: 1: 0.5.

[0100] The above-mentioned low-hardness rubber material has the preparat...

PUM

| Property | Measurement | Unit |

|---|---|---|

| hardness | aaaaa | aaaaa |

| hardness | aaaaa | aaaaa |

| hardness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com