Perishable garbage in farm product markets based organic fertilizer production method

A technology for farmers' markets and production methods, which is applied in the direction of organic fertilizers, preparation of organic fertilizers, and treatment of bio-organic parts. It can solve the problems of difficult control of organic fertilizer efficiency and insufficient deodorization treatment, and achieve good particle formation and thorough recycling. , good fertilizer effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

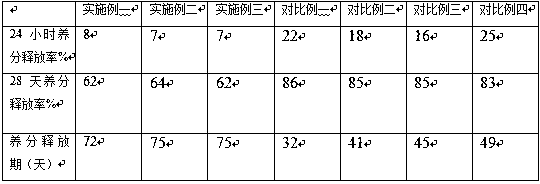

Examples

Embodiment 1

[0031] The organic fertilizer production method based on the perishable garbage in the farmer's market comprises the following steps:

[0032] (1) Removal of impurities, sorting and removing impurities in the garbage that cannot be made into organic fertilizers, such as metals, stones, etc.;

[0033] (2) Press filter to dehydrate the cleaned garbage, control the pressure of filter at 0.1-0.2MPa, press filter until the water content of the filter residue is 60%, and obtain the filter residue and filtrate;

[0034] (3) mechanically crushing the filter residue to obtain filter residue fragments;

[0035] (4) Add the filter residue fragments to the filtrate to ensure that the solid content is 30%. If the filtrate is insufficient to replenish water, add additives at the same time, stir for 1 hour at a temperature of 25 degrees Celsius, and stand for 2 hours to obtain a slurry; additives Including diatomaceous earth, starch-based plastics, and garbage base materials, the weight rat...

Embodiment 2

[0039] The organic fertilizer production method based on the perishable garbage in the farmer's market comprises the following steps:

[0040] (1) Removal of impurities, sorting and removing impurities in the garbage that cannot be made into organic fertilizers, such as metals, stones, etc.;

[0041] (2) Press filter and dehydrate the cleaned garbage, control the pressure of filter at 0.2-0.3MPa, press filter until the water content of the filter residue is 65%, and obtain the filter residue and filtrate;

[0042] (3) mechanically crushing the filter residue to obtain filter residue fragments;

[0043] (4) Add the filter residue fragments to the filtrate to ensure that the solid content is at 25%. If the filtrate is not enough to replenish water, add additives at the same time, stir at 40 degrees Celsius and pass oxygen treatment for 1.5 hours, and stand for 3 hours to obtain Slurry; additives include diatomaceous earth, starch-based plastics, and garbage base materials, with...

Embodiment 3

[0050] The organic fertilizer production method based on the perishable garbage in the farmer's market comprises the following steps:

[0051] (1) Removal of impurities, sorting and removing impurities in the garbage that cannot be made into organic fertilizers, such as metals, stones, etc.;

[0052] (2) Press filter and dehydrate the cleaned garbage, control the pressure of the filter at 0.1-0.3MPa, press filter until the water content of the filter residue is 70%, and obtain the filter residue and filtrate;

[0053] (3) mechanically crushing the filter residue to obtain filter residue fragments;

[0054] (4) Add the filter residue fragments to the filtrate to ensure that the solid content is at 25%. If the filtrate is insufficient to replenish water, add additives at the same time, stir at 25 degrees Celsius and pass oxygen treatment for 1.5 hours, and stand for 3 hours to obtain Slurry; additives include diatomaceous earth, starch-based plastics, and garbage base materials...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle diameter | aaaaa | aaaaa |

| hardness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com