Instant compression and expansion type garbage collection and environment-friendly trolley

A capacity-expanding, garbage-based technology, applied in the direction of garbage receptacle, transportation and packaging, etc., can solve the problems of reduced compression efficiency and effect, no instant expansion of garbage bins, simple structure, etc., and achieve the effect of speeding up the time

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0036] Below in conjunction with accompanying drawing and embodiment of description, specific embodiment of the present invention is described in further detail:

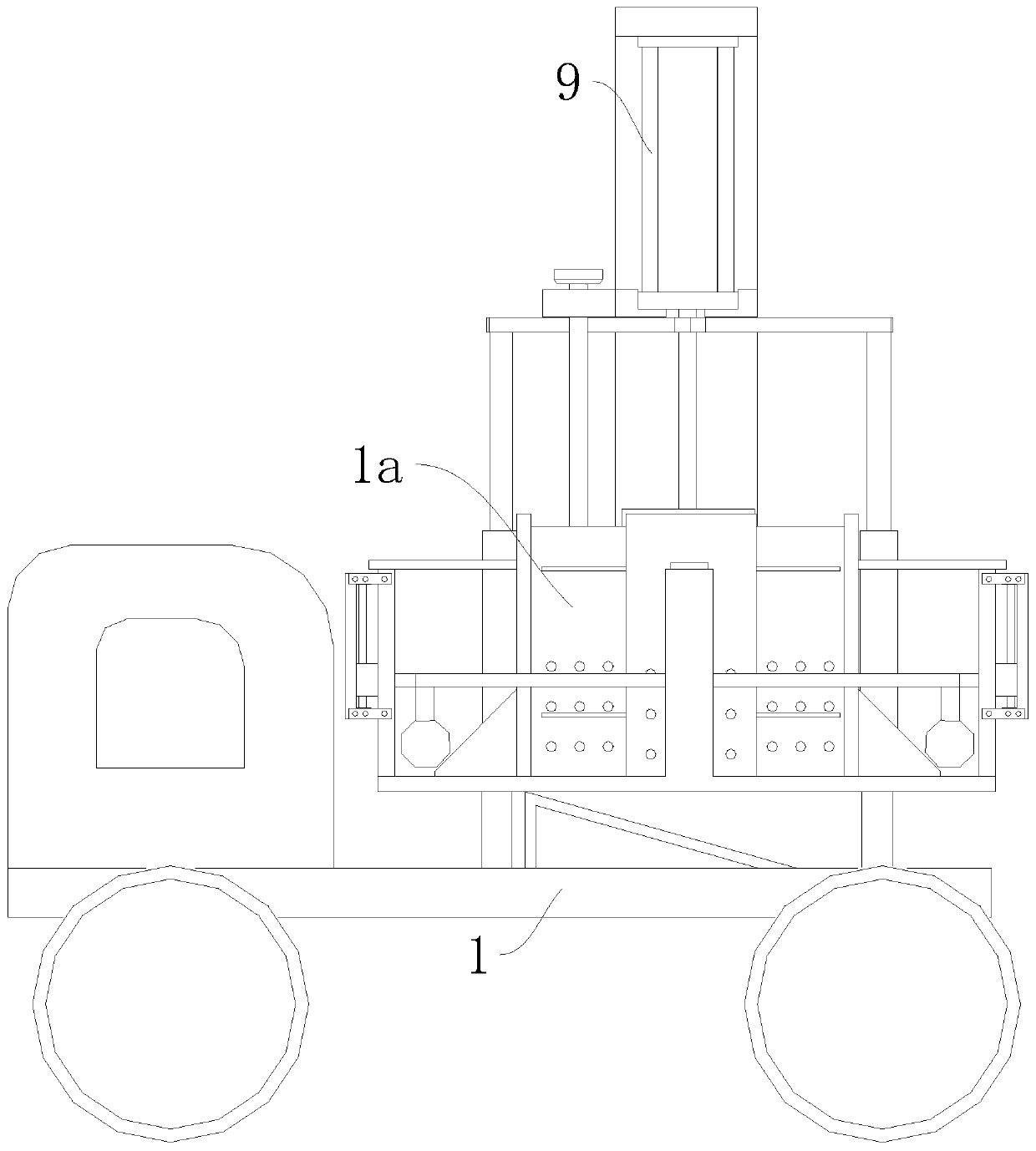

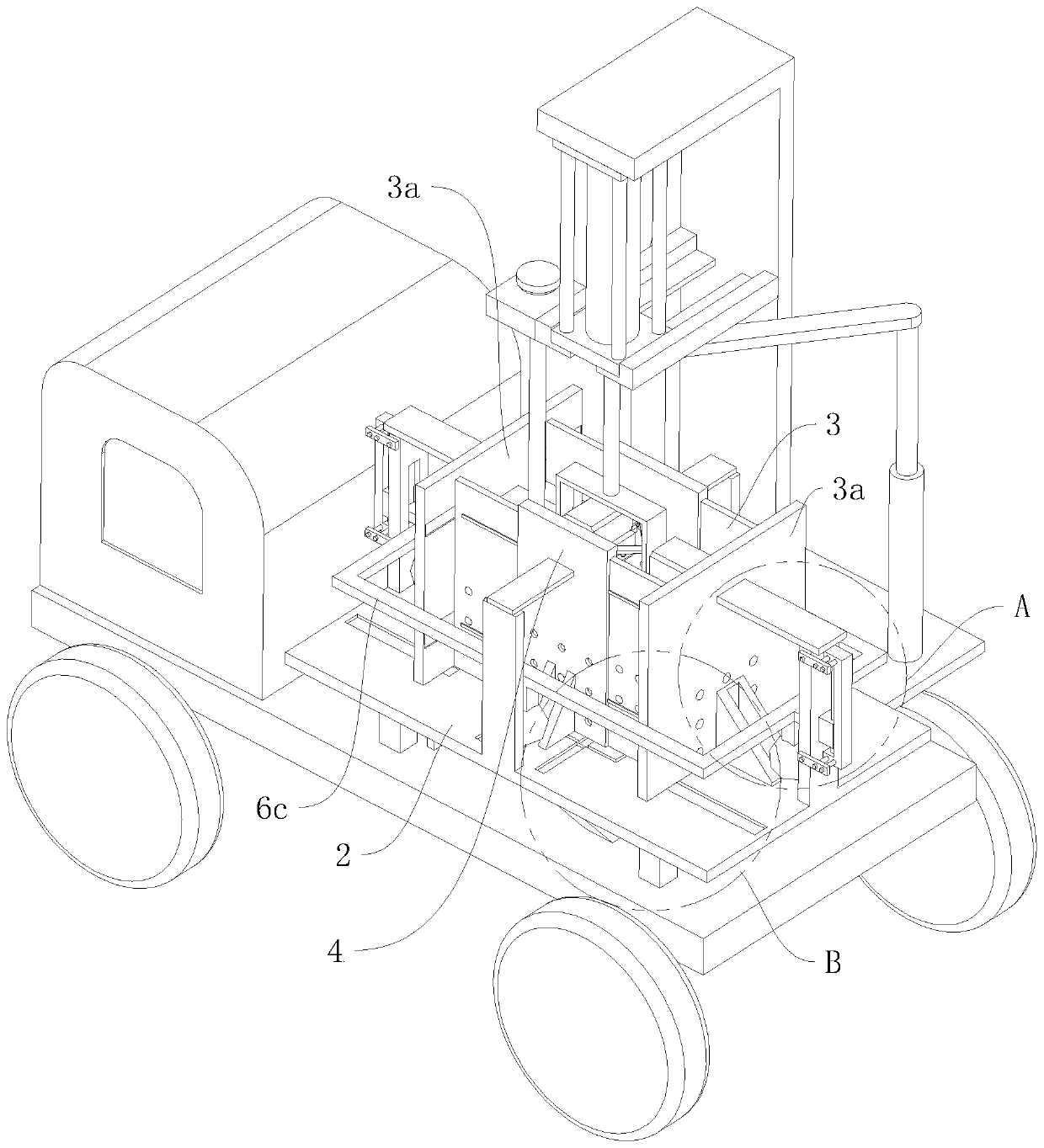

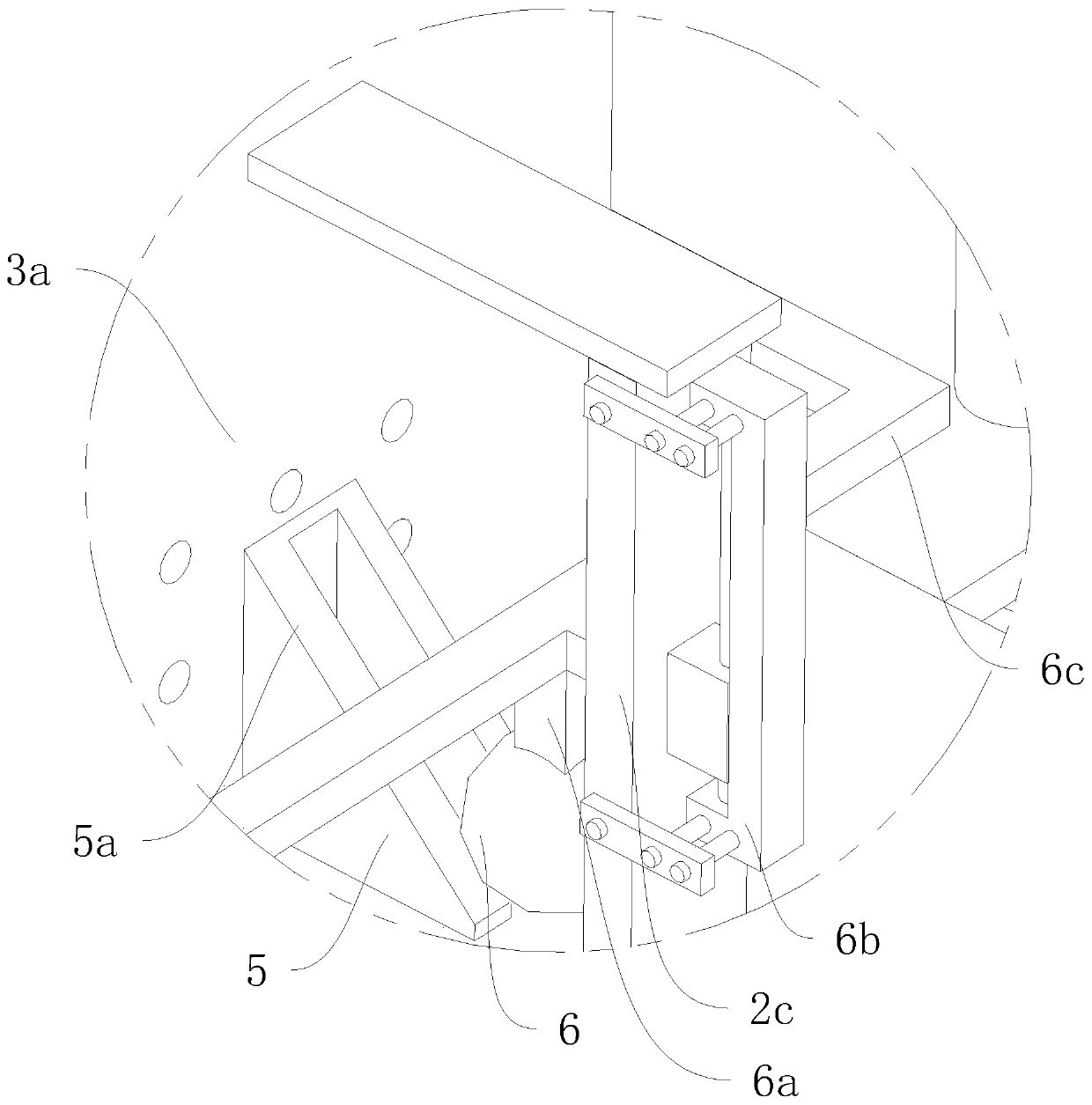

[0037] refer to Figure 1 to Figure 11The shown one kind of instant compression and expansion type garbage removal environmental protection trolley includes a car body 1, an expansion bin 1a installed on the car body 1 and a compression mechanism arranged directly above the expansion bin 1a. The expansion bin 1a includes a bearing plate 2, Two first baffles 3a and two second baffles are arranged symmetrically, the bearing plate 2 is erected horizontally on the vehicle body 1, and the two first baffles 3a are vertical and can face or back The two second baffles are vertically arranged on the top of the bearing plate 2, and can be arranged on the top of the bearing plate 2 facing or facing away from each other, and the two are always between the two first baffles 3a , the two ends of the two second baffles are respec...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com