Pipe hot blow molding production platform

A technology for producing platforms and pipe fittings, applied in applications, household appliances, tubular items, etc., can solve problems such as inability to change pipe fittings, and achieve the effects of high production efficiency, high promotion value, and scientific and reasonable structural design.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

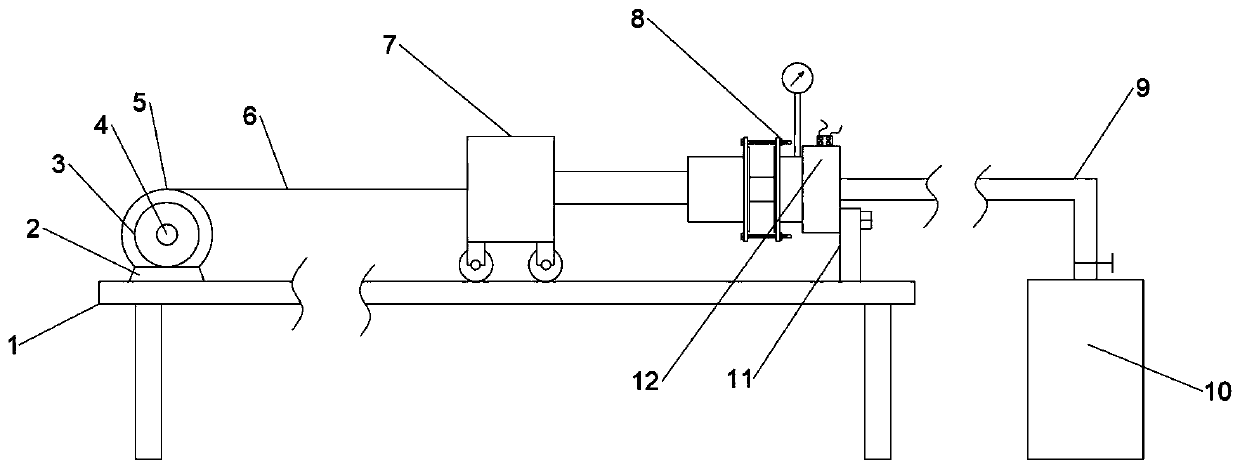

[0028] The present invention is a hot blow molding production platform for pipe fittings, which includes a high-pressure gas cylinder 10 and a workbench 1. The left side of the workbench 1 is fixedly connected with a mounting plate 11, and a thermoplastic mold 8 and a thermoplastic mold 8 are installed on the mounting plate 11. There is a clamping trolley 7 on the left side. The clamping trolley 7 moves on the workbench 1. A wire rope 6 is attached to the left side of the clamping trolley 7, and the other end of the wire rope 6 is wound on the winding wheel 5, and the winding wheel 5 passes through the shaft 4 Connected to the motor 3, the raw material pipe 9 is connected to the high-pressure gas cylinder 10, the raw material pipe 9 passes through the thermoplastic mold 8, the clamping trolley 7 clamps and seals the end of the raw material pipe 9, and the left part of the thermoplastic mold 8 is covered with electric heating Set of 12.

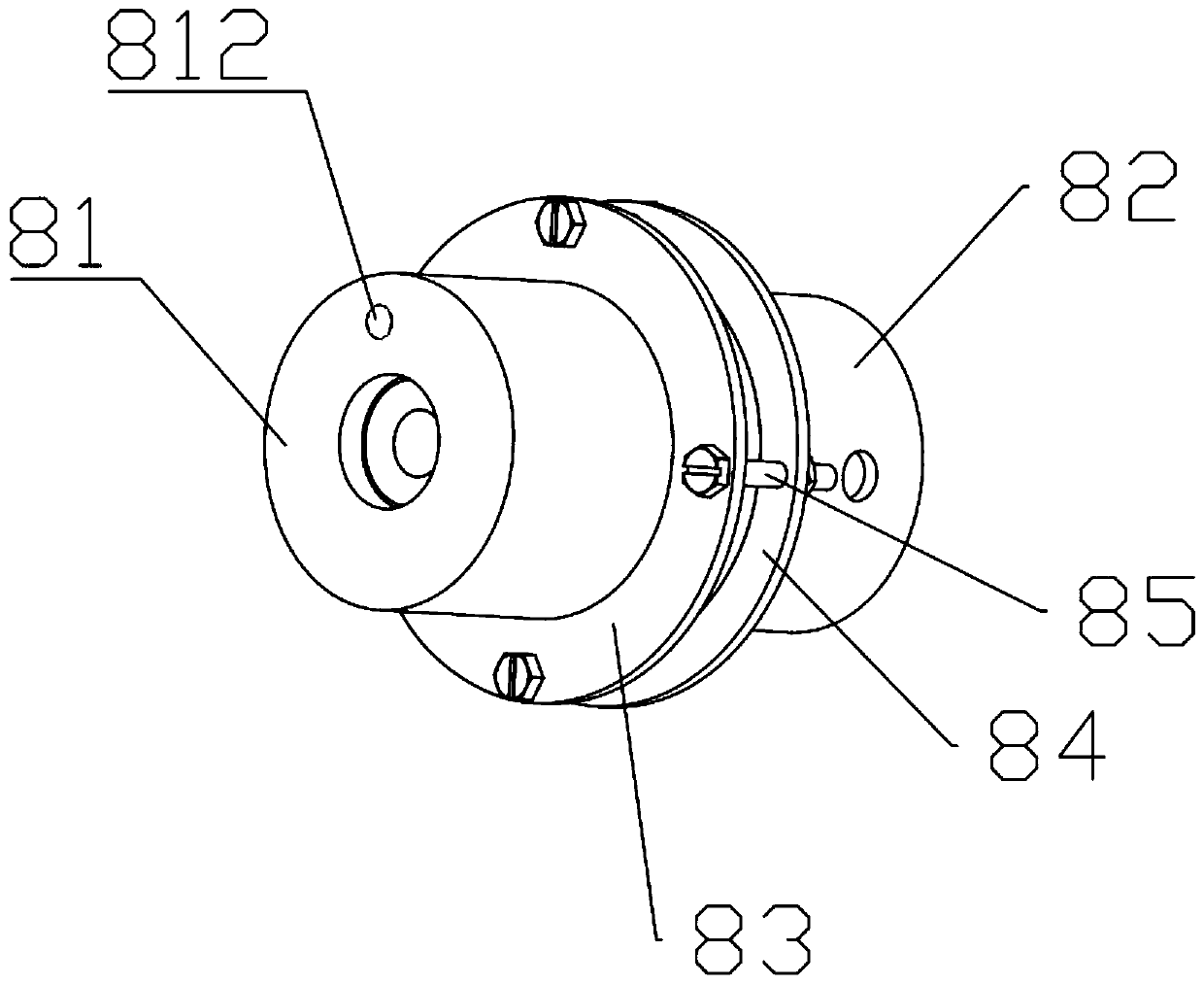

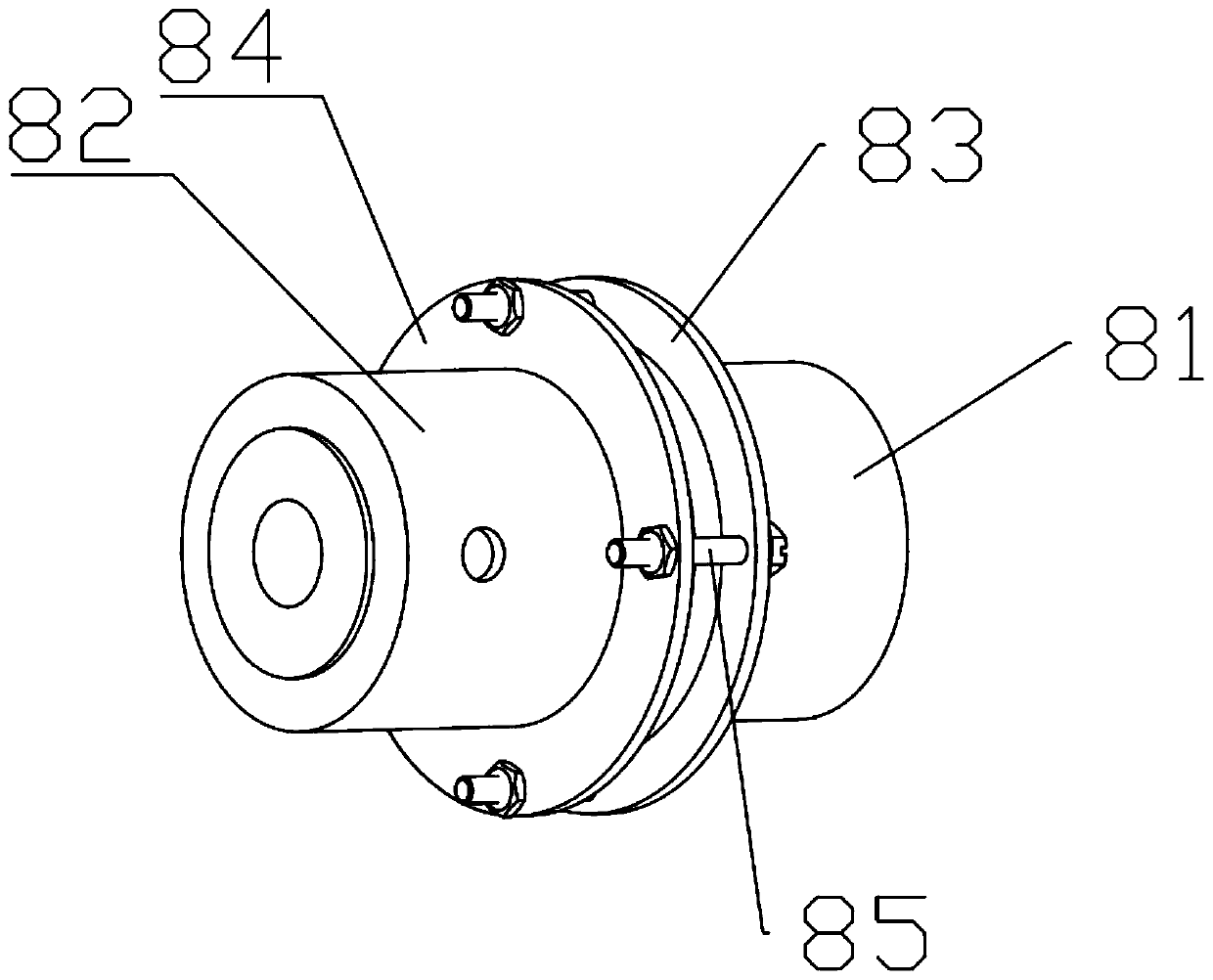

[0029] The thermoplastic mold 8 includes a...

Embodiment 2

[0035] The difference from Embodiment 1 is that the inner diameter of the copper pipe 86 is a variable diameter, one end has the same diameter as the feed through hole 813, and the other end has the same diameter as the discharge through hole 824, which makes the pipe more uniform in diameter reduction.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com