Dismounting method of energy storage spring for 10 kV metalclad withdraw switchgear circuit breaker

A technology of energy storage spring and disassembly method, which is applied in the direction of manufacturing tools, hand-held tools, etc., can solve the problems of not too obvious effect, no stress point, and laborious use, so as to shorten the maintenance time of power failure and improve the disassembly and assembly efficiency , Easy and fast operation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1)

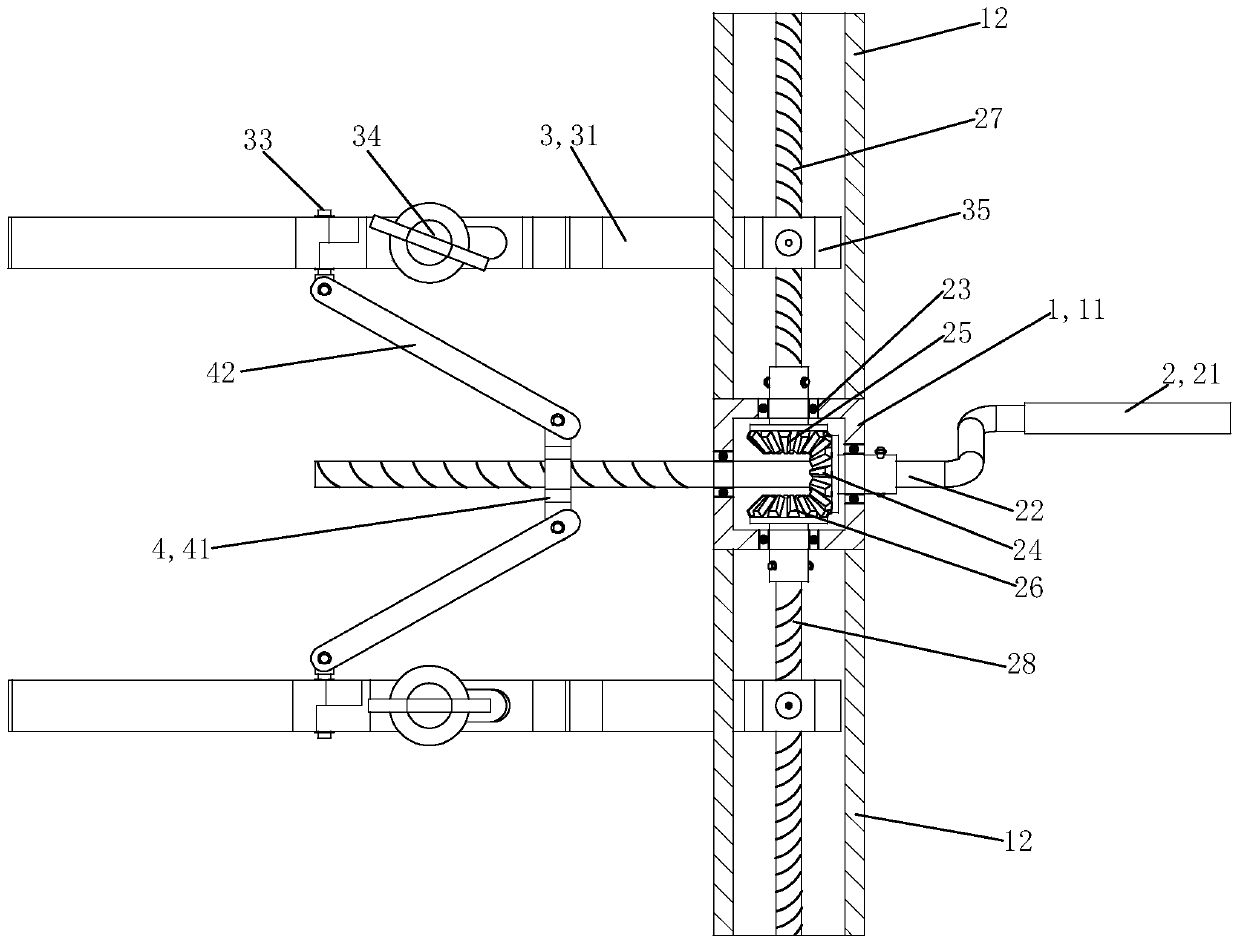

[0033] In this embodiment, when describing the orientation, use figure 1 The direction facing is the front in the description, with the back facing figure 1 The direction facing is the rear in the description, figure 1 The up and down, left and right directions in the description are still the up and down, left and right directions in the description.

[0034] See figure 1 , the method for disassembling and assembling the energy storage spring of the 10kV central cabinet circuit breaker in this embodiment is implemented by using a special tool designed as a set. composition.

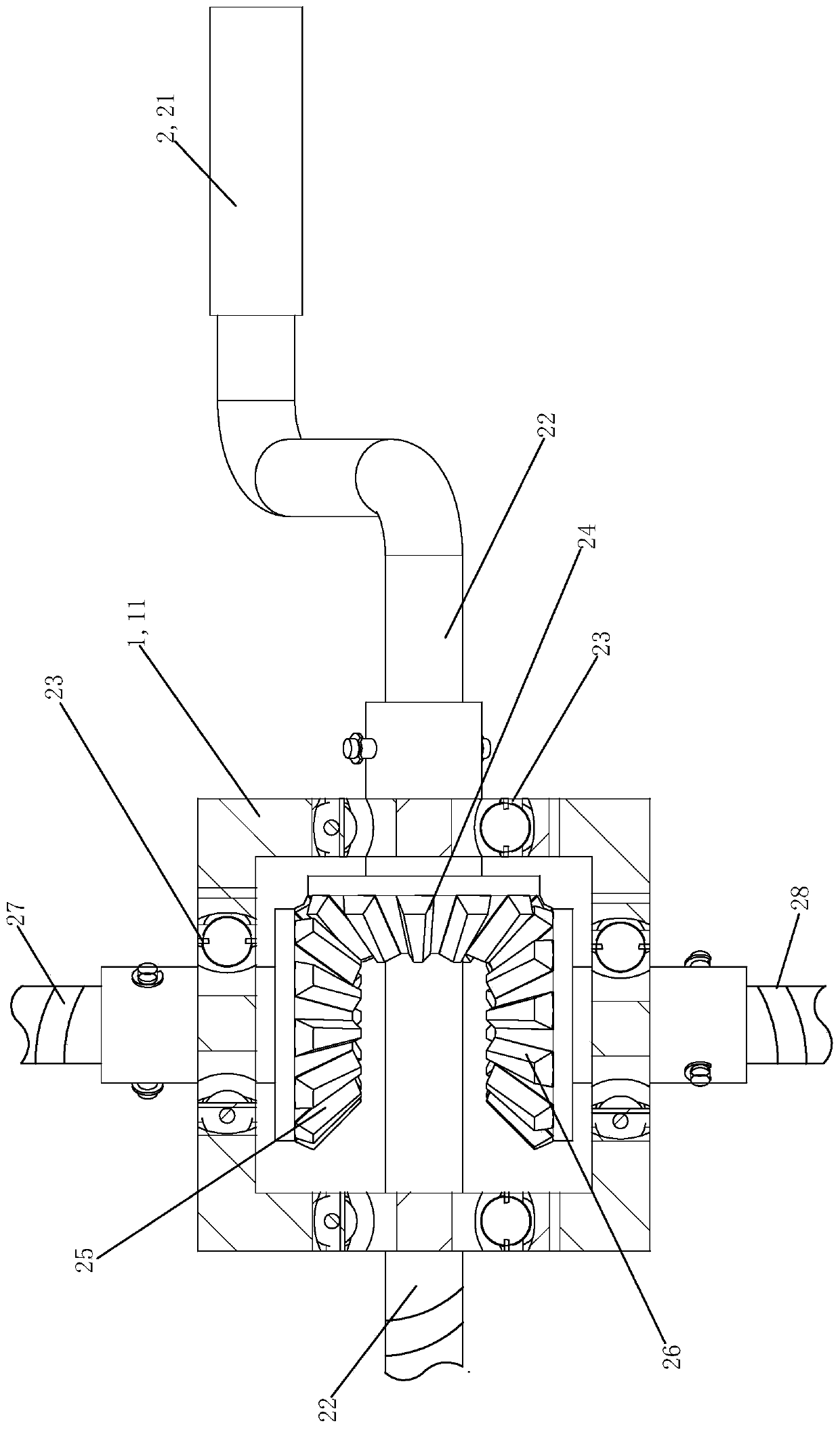

[0035] see figure 2 , The body 1 is mainly composed of a gear box 11 and a mounting sleeve 12 . The gear case 11 is a hollow square box body part surrounded by each of the front, rear, upper, lower, left and right plates. The upper plate, the lower plate, the left plate and the right plate of the gear case 11 are respectively provided with A total of 4 bearing mounting holes 11-1. The installatio...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com