A grid slot film cooling structure with spool type spoiler column and double rounded outlets

A spoiler column and grid technology, applied in the direction of blade support elements, machines/engines, mechanical equipment, etc., can solve the problems of inability to form air film coverage near the wall and weak span-wise coverage, and achieve enhanced flow-direction coverage , eliminate low-speed reflux vortex, and increase heat transfer area

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

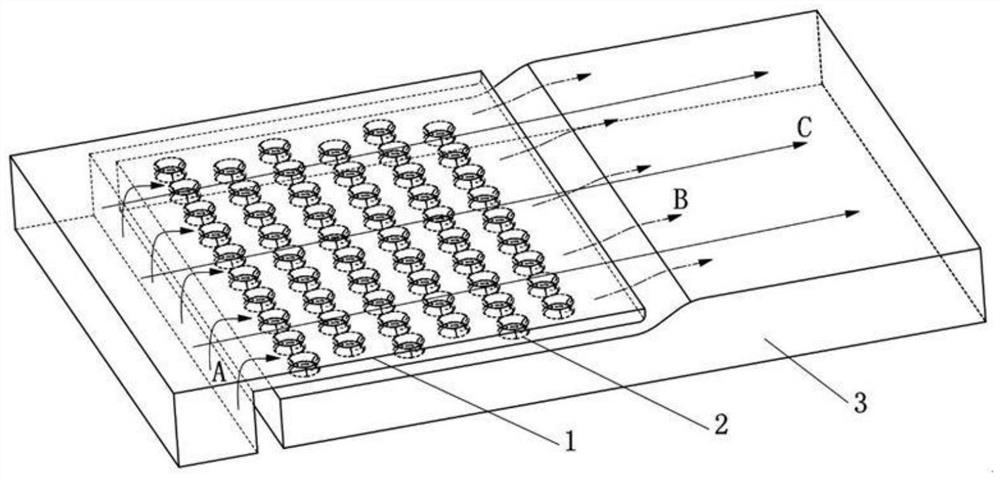

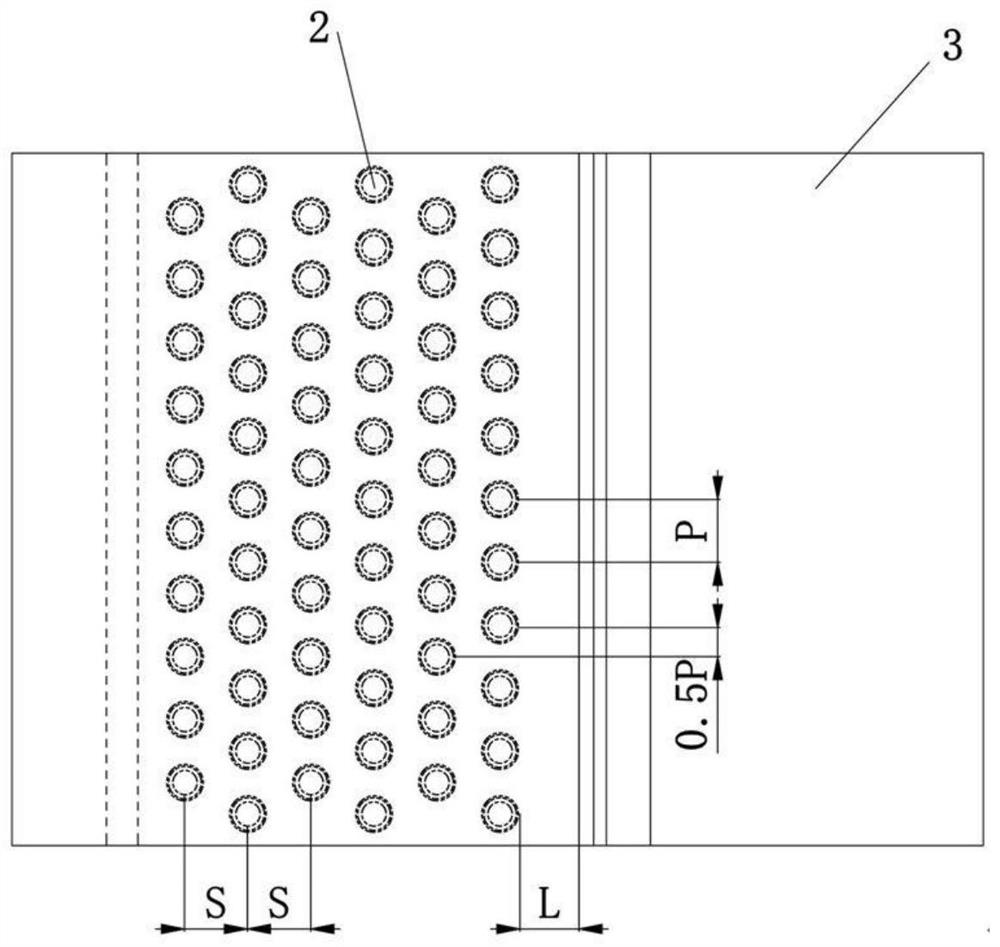

[0028]This embodiment is applied to the turbine guide vane; the suction surface of the turbine blade is arranged near the leading edge of the blade with a spool type spoiler and a grid slot structure 5 with the suction surface close to the leading edge of the blade, and the air is supplied by the internal cooling passage 4; wherein , the two-dimensional grid seam structure formed by the lip plate 1 and the bottom plate 3 is provided with a bobbin-type spoiler column 2, the bobbin-type spoiler column 2 is arranged in a fork row, and a double-rounded structure is adopted at the outlet of the grid seam. The external profiles of the lip plate 1 and the bottom plate 3 in the grid slot air film cooling structure with spool type spoiler columns and double rounded outlets are flush. The diameter D of the outer disk of the spool spoiler 2 is 0.6mm; the diameter d of the lumbar disk of the spool spoiler 2 is 0.4mm; the radius R of the outer disk rounding of the spool spoiler 2 is 0.1d ,...

Embodiment 2

[0030] This embodiment is a grid slit air film cooling structure with a spool type spoiler column and double rounded outlets applied to the turbine guide vane. On the pressure surface of the turbine blade, a spoiler column with a spool and a grid slot structure 7 on the pressure surface are arranged, and the air is supplied by the internal cooling channel 6 . Among them, the two-dimensional grid seam structure formed by the lip plate 1 and the bottom plate 3 is provided with a bobbin-shaped spoiler column 2, and the bobbin-shaped spoiler post is arranged in a row, and the outlet of the grid seam adopts a double-rounded structure. The outer profiles of the lip plate and the bottom plate in the grid-slit air film cooling structure with spool-type spoiler columns and double rounded outlets are flush. The diameter D of the outer disc of the spool spoiler 2 is 0.9mm, the diameter d of the waist disc of the spool spoiler 2 is 0.6mm, and the rounding radius R of the outer disc of the...

Embodiment 3

[0032] This embodiment is a grid slit air film cooling structure with a spool type spoiler column and double rounded outlets applied to the turbine guide vane. The pressure surface of the turbine blade is arranged near the leading edge of the blade with a spool type spoiler column and a grid slot structure 9 with the pressure surface close to the trailing edge of the blade. The dimensional grid seam structure is provided with a bobbin-shaped spoiler column 2, which is arranged in a fork row, and the exit of the grid seam is a double-rounded structure. The lip plate 1 in the grid slot air film cooling structure is flush with the outer surface of the bottom plate 3 . The diameter D of the outer disc of the spool spoiler 2 is 1mm, the diameter d of the waist disc of the spool spoiler 2 is 0.4mm, and the rounding radius R of the outer disc of the spool spoiler 2 is 0.12d , the rounding radius r of the spool type spoiler column 2 is 0.14d. The value of the spanwise spacing P of t...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com