Shield tunneling machine with end face freezing system and protection method thereof

A technology of shield machine and end face, which is applied in the direction of earth drilling, mining equipment, tunnels, etc. It can solve problems such as wear and tear, tool replacement, and poor pressure-holding characteristics of the formation, achieving high economic applicability and improving safety.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0024] In order to deepen the understanding of the present invention, the present invention will be further described below in conjunction with the examples, which are only used to explain the present invention, and do not constitute a limitation to the protection scope of the present invention.

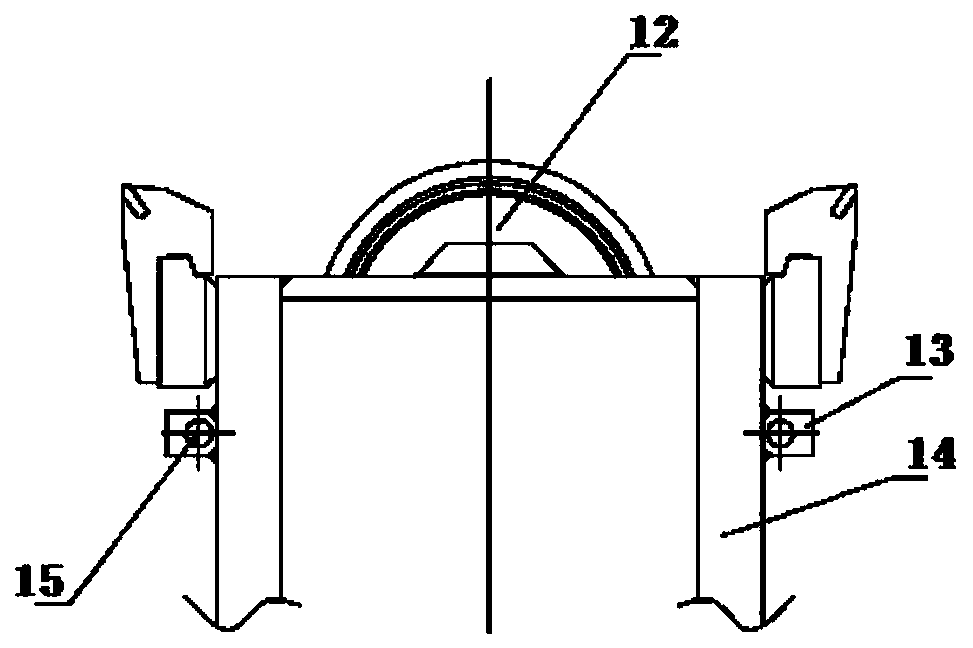

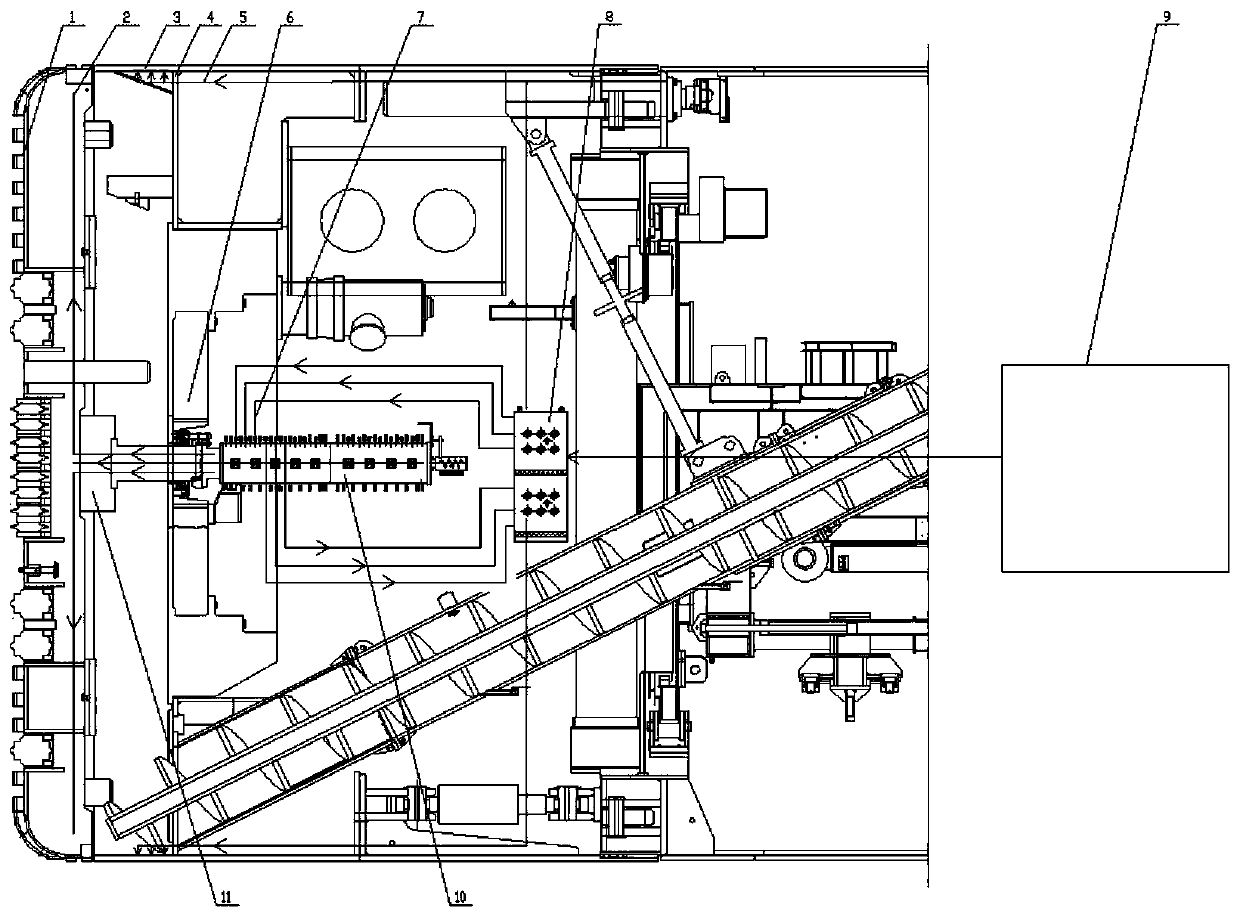

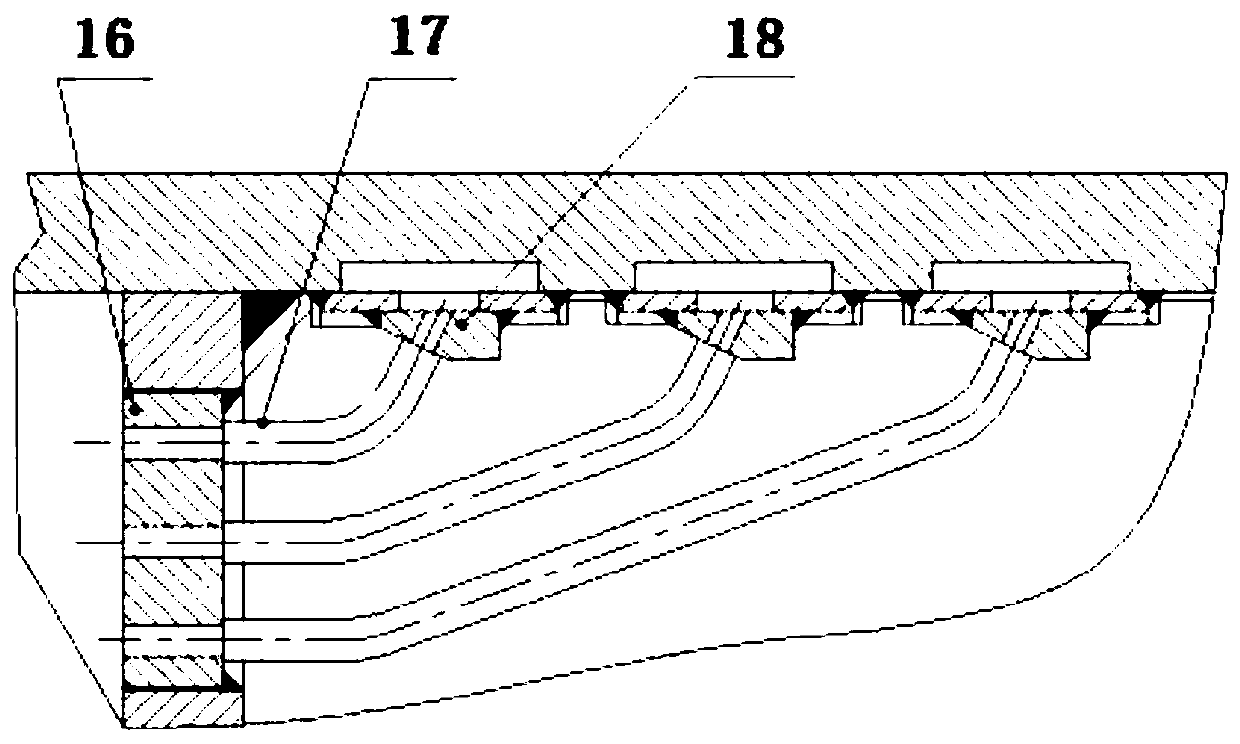

[0025] according to figure 1 , 2 As shown, the present invention proposes a shield machine with an end-face freezing system, including a cutter head 1, a front shield 2, a central rotating body 10, a quick connection device 8 and a refrigerator system 9, and the radial plate of the cutter head 1 At least one cutterhead freezing tube 2 is arranged, and each cutterhead freezing tube 2 is embedded in the square steel inside the cutterhead 1, and the cutterhead 1 is connected to the cutterhead central block 11 behind, and the cutterhead central block 11 is connected to The central rotator 10, the middle part of the central rotator 10 is connected with the main drive 6, and the main driv...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com