Self-compacting concrete pouring method and pouring tool thereof

A self-compacting concrete and concrete technology, applied in construction, building structure, construction material processing and other directions, can solve the problems of concrete waste, hidden dangers to the personal safety of pouring personnel, etc., to reduce construction costs, improve safety, and expand the opening section. The effect of size

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0022] Embodiment 1: A method for pouring self-compacting concrete.

[0023] The invention provides a kind of pouring method of pouring concrete, and this pouring method comprises the following steps:

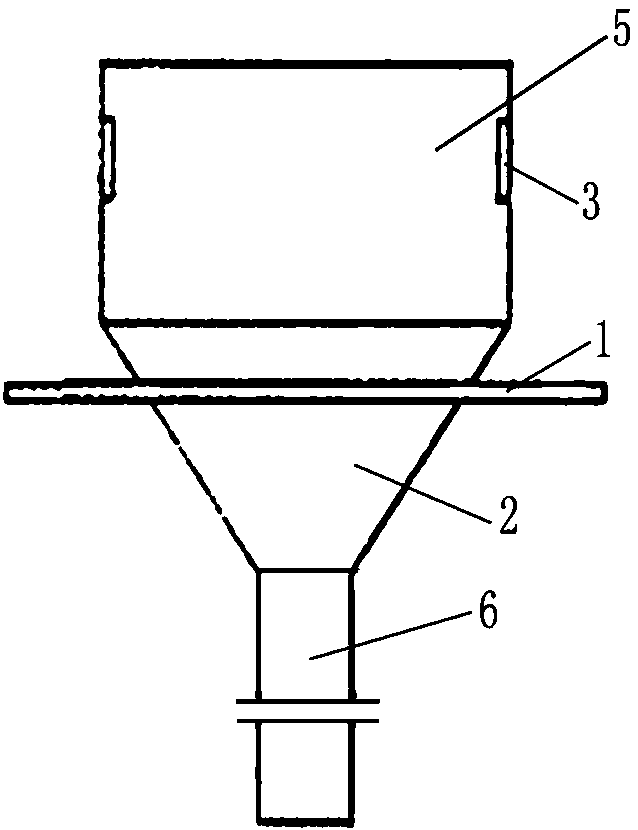

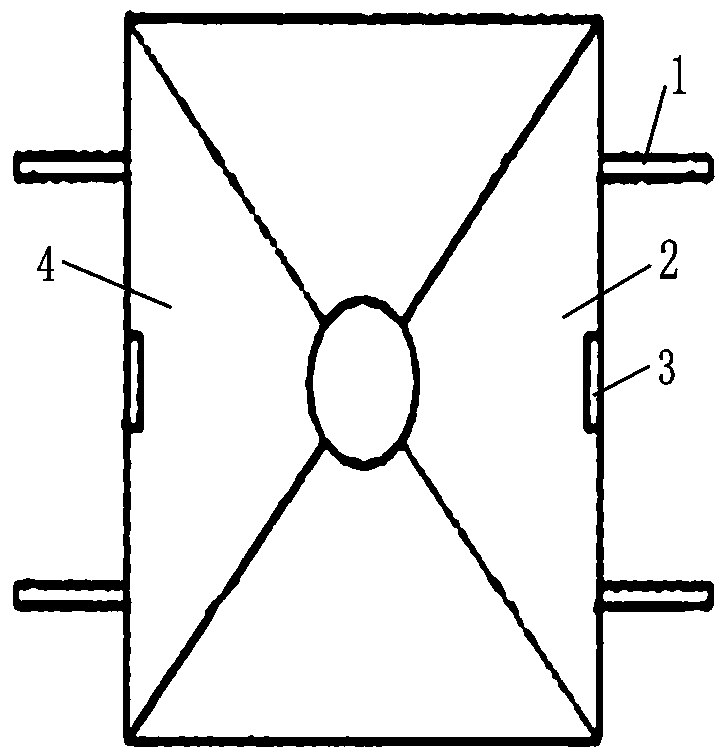

[0024] Firstly, a self-compacting pouring tool is prepared, and the self-compacting pouring tool includes a funnel and a support beam 1 arranged on the outer wall of the funnel. The funnel includes a rectangular cylinder 5 arranged at the upper end, an inclined cylinder 2 connected to the lower end of the rectangular cylinder 5 , and a guide cylinder 6 connected to the lower end of the rectangular cylinder 5 . The rectangular cylinder 5 is a hollow cylindrical body with a rectangular cross-section surrounded by four rectangular plates. The inclined cylinder 2 is surrounded by four inclined plates 4 corresponding to the rectangular plates. The rectangular plate shrinks obliquely from the connection end with the rectangular cylinder 5 to the middle of the funnel, and forms a rou...

Embodiment 2

[0030] Embodiment 2: A self-compacting concrete pouring tool.

[0031] like figure 1 , figure 2 As shown, the present invention provides a self-compacting concrete pouring tool, the structure of which includes a funnel and a support beam 1 arranged on the outer wall of the funnel. The funnel includes a rectangular cylinder 5 arranged at the upper end, an inclined cylinder 2 connected to the lower end of the rectangular cylinder 5 , and a guide cylinder 6 connected to the lower end of the rectangular cylinder 5 . The rectangular cylinder 5 is a hollow cylindrical body with a rectangular cross-section surrounded by four rectangular plates. The inclined cylinder 2 is surrounded by four inclined plates 4 corresponding to the rectangular plates. The rectangular plate shrinks obliquely from the connection end with the rectangular cylinder 5 to the middle of the funnel, and forms a round hole at the lower end. The contracted end It is in contact with the hollow cylindrical guide ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com