Hydraulic lifting clamping jaw

A technology of hydraulic lifting and gripping claws, which is applied in the direction of trolley cranes, load hanging components, cranes, etc., can solve the problems of poor safety, low efficiency, and gripping claws that cannot meet the gripping requirements, and achieve the effect of strong gripping ability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0030] The present invention will be further described through specific embodiments below in conjunction with the accompanying drawings.

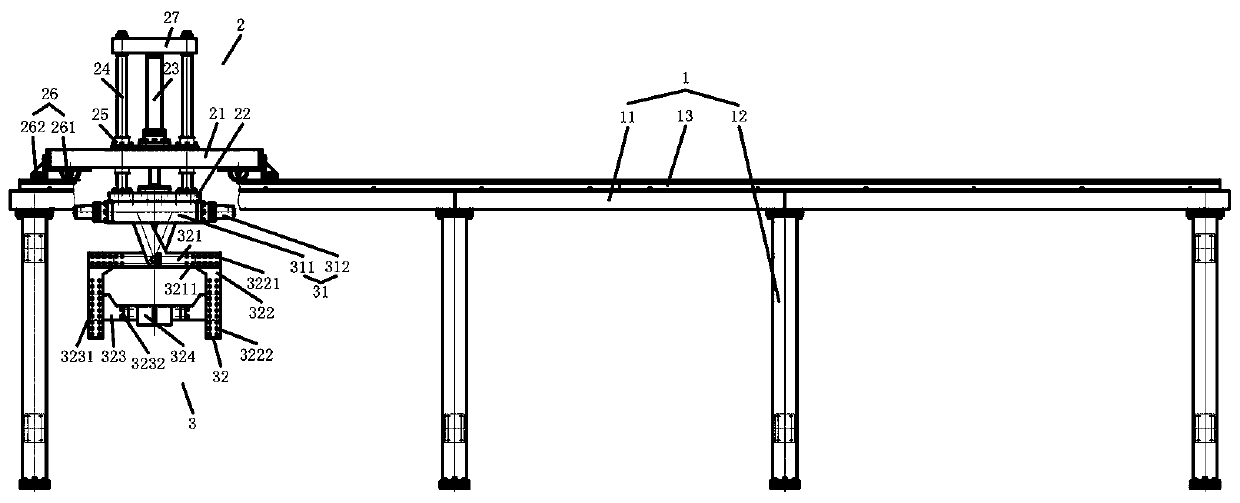

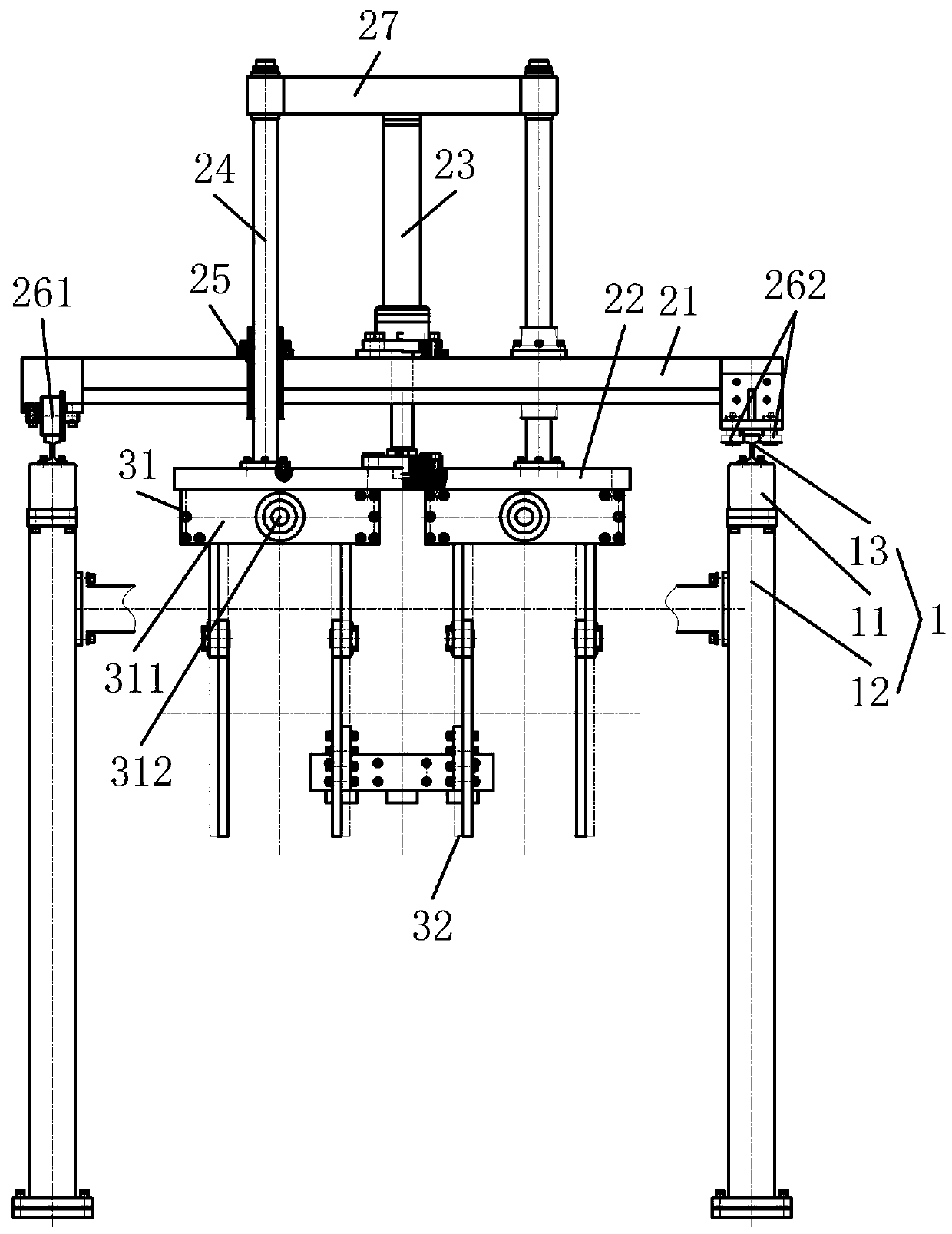

[0031] like figure 1 , figure 2 , a hydraulic lifting jaw, comprising:

[0032] The support frame 1, the support frame 1 includes two horizontally arranged and parallel translation support rods 11, a support leg 12 installed below the translation support rods 11 and a guide rail 13 installed above the translation support rods 11;

[0033] Move the lifting frame 2, the moving lifting frame 2 includes a horizontal support 21 installed on the guide rail 13, a lifting connection seat 22 located below the horizontal support 21, and a vertically installed on the horizontal support 21, and the piston rod end and the center position of the lifting connection seat 22 The connected lifting cylinder 23 is vertically connected to the guide rod 24 around the lifting connection seat 22 and passes through the horizontal support 21;

[0034] Gripper me...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com