A construction method for manufacturing FRP floating trays by spraying process

A construction method and technology of glass fiber reinforced plastics, applied in the direction of surface coating liquid device, coating, engine sealing, etc., can solve the problems of material waste, waste, low production efficiency, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

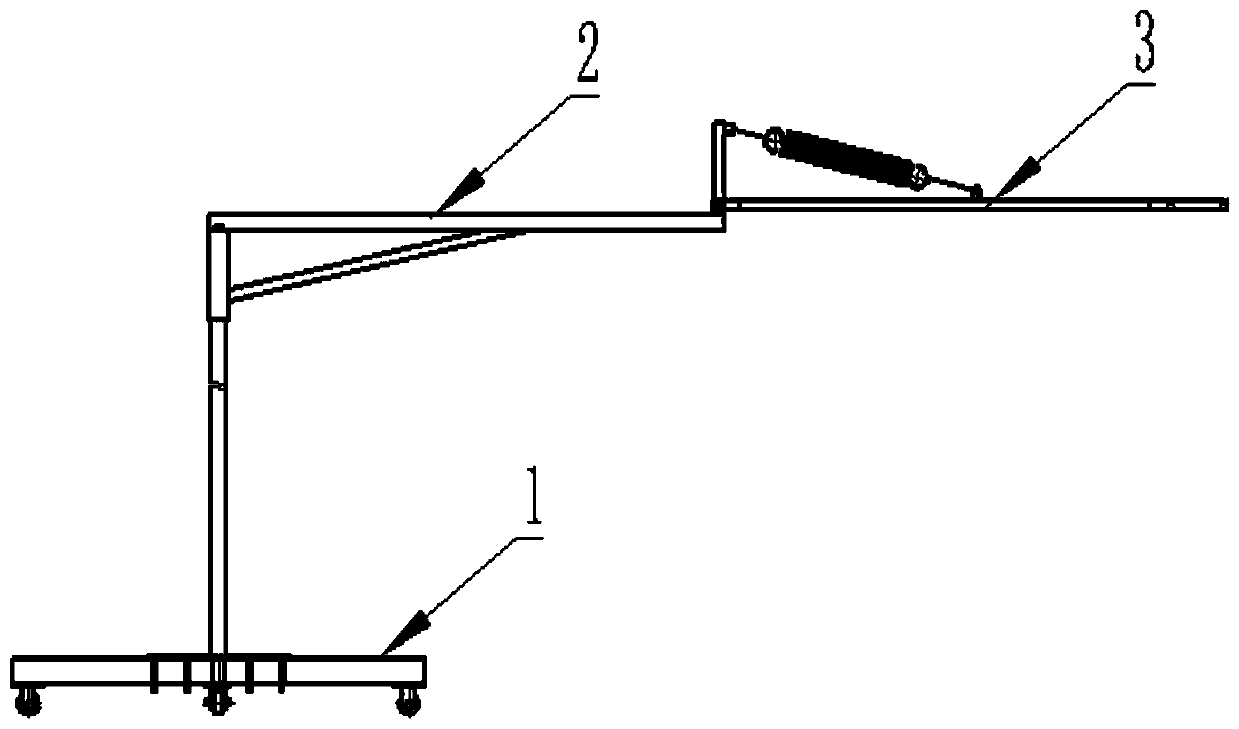

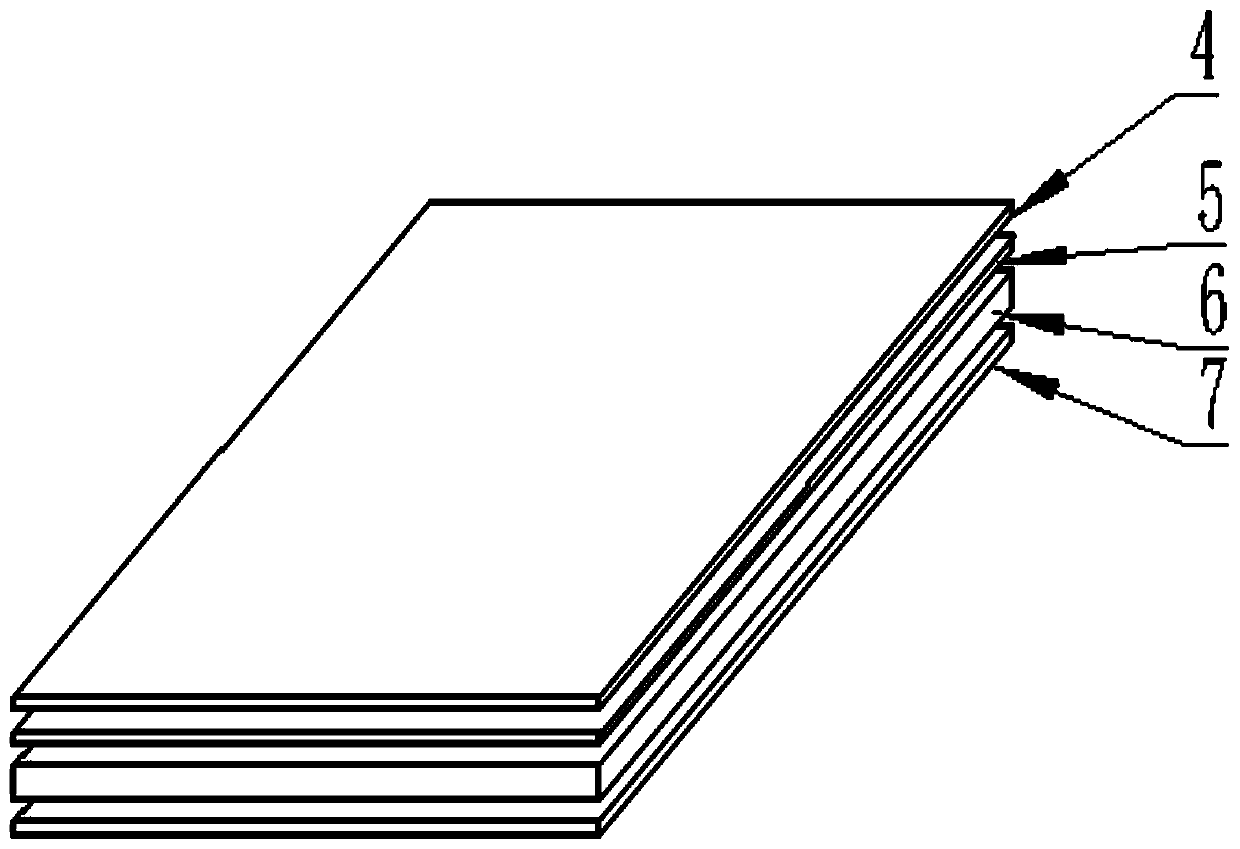

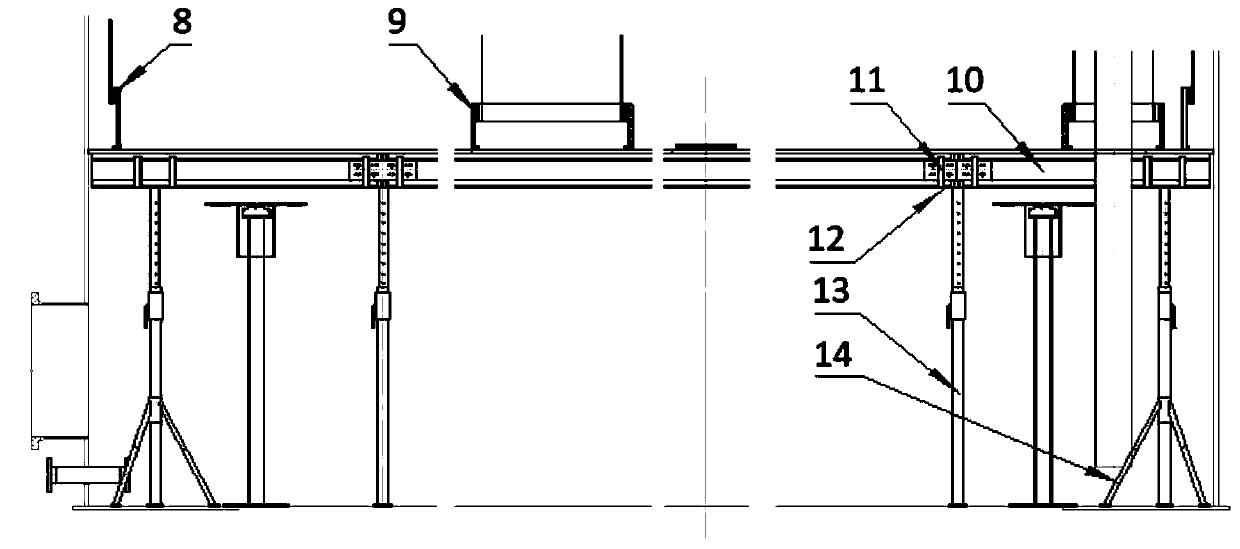

[0088]The production of FRP floating trays by spraying process of the present invention is a novel technology for FRP construction. In the spraying process, the spray gun is used as the basic construction tool, combined with various spraying special tools, can effectively improve the efficiency of FRP construction. Due to the use of the spray gun, the resin and the curing agent are supplied by two pumps together, driven by one pump, ensuring mixing The precision and consistency, and mixing at the outlet of the spray gun, can be stopped at any time, no waste, saving materials. Spraying continuous glass fiber replaces chopped strand mat and glass cloth, and the glass fiber is driven by a special cutter, so that the ratio of resin to glass fiber is also very precise, which improves the quality of FRP construction.

[0089] The main tool for producing FRP floating discs by spraying process is FRP spray gun. Its working principle is: the fast motor pulls out the fiber, uses scisso...

PUM

| Property | Measurement | Unit |

|---|---|---|

| diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com