an automatic seat belt

A seat belt, automatic technology, applied in the passive seat belt system and other directions, can solve the problem of low safety awareness of passengers and achieve the effect of ensuring safety

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

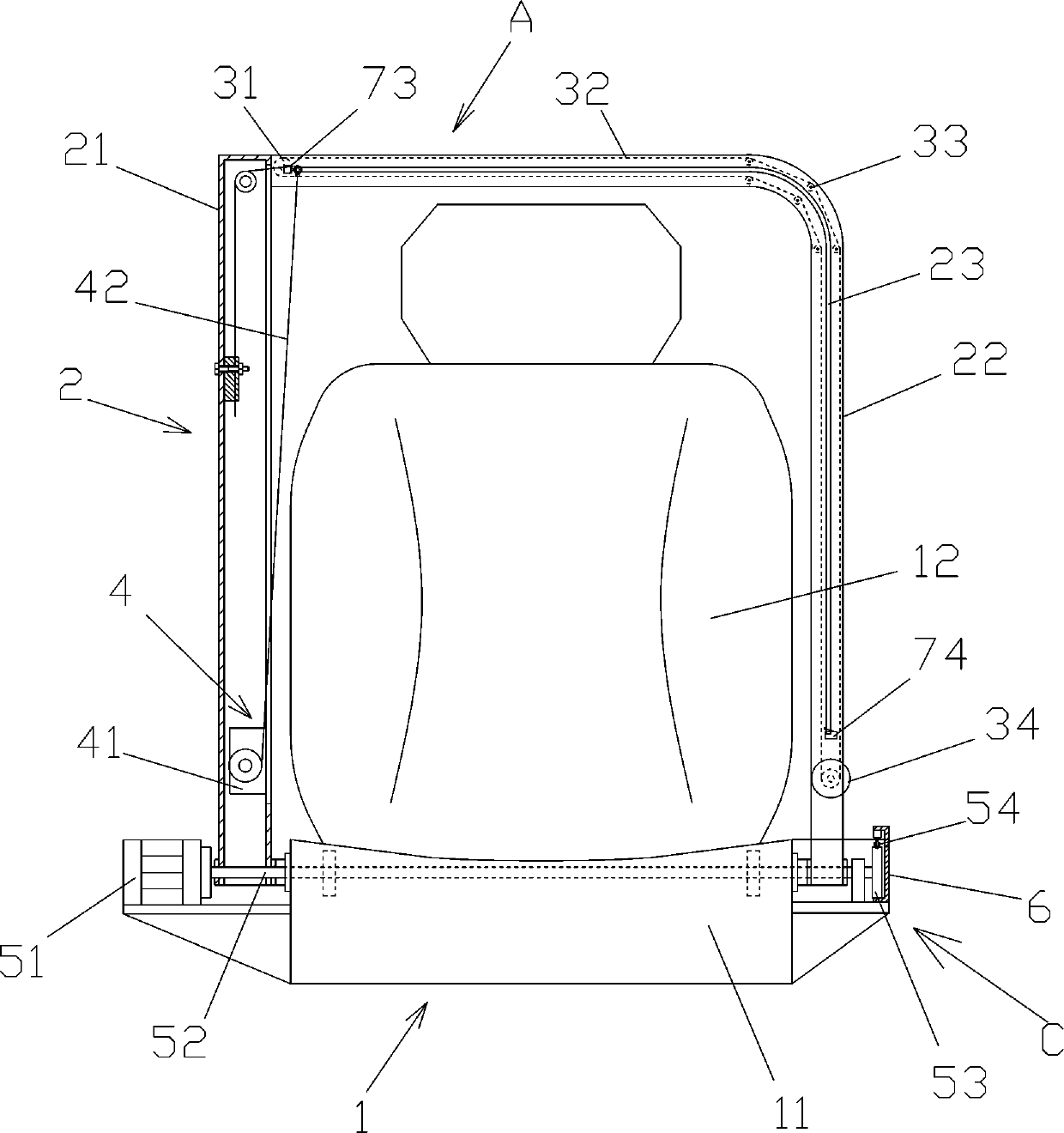

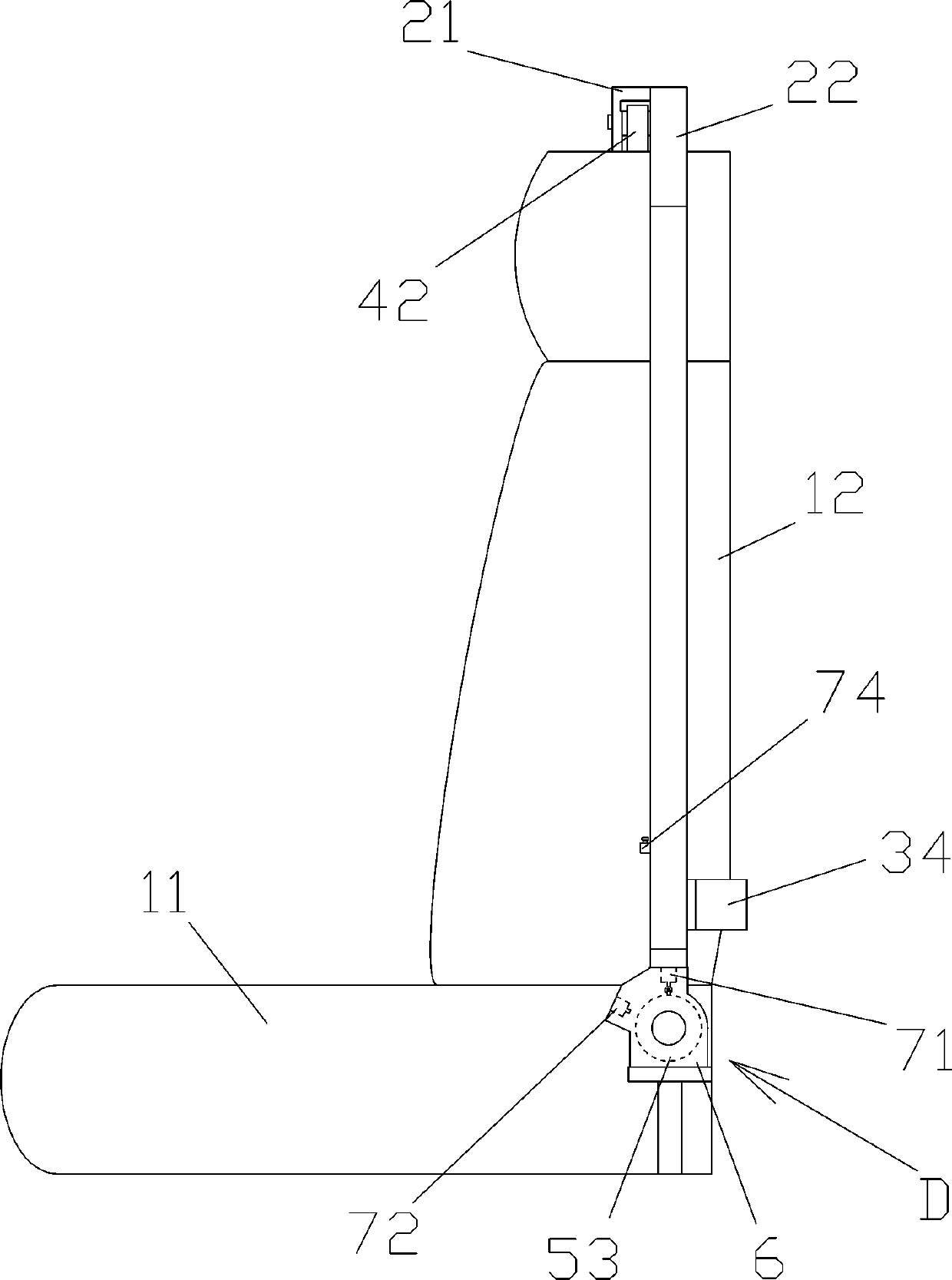

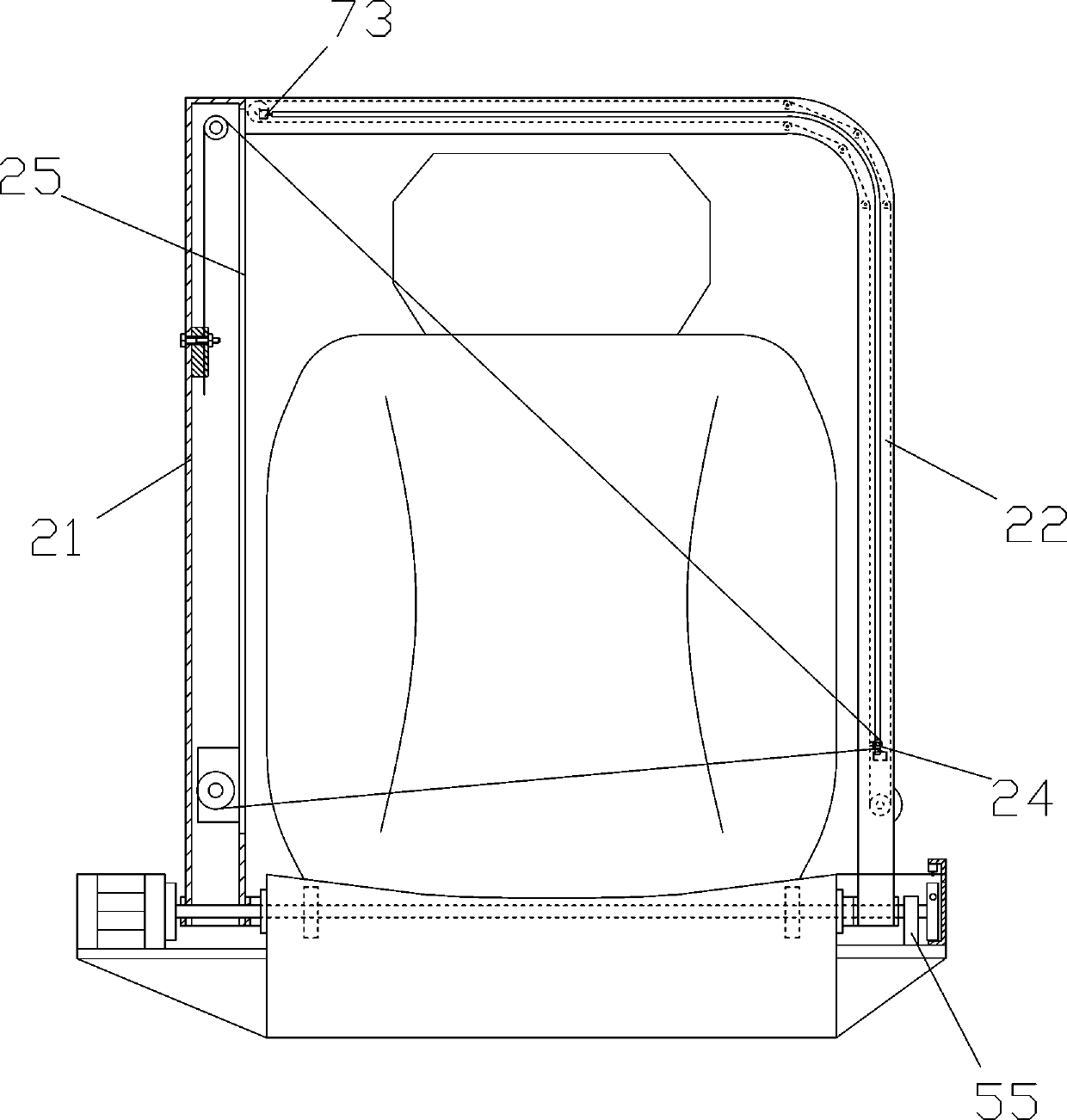

[0020] Such as Figures 1 to 8 As shown, an automatic safety belt includes a seat 1, the seat 1 includes a seat cushion 11 and a backrest 12, a rotating shaft 52 and a plurality of axle seats 55 are installed in the seat cushion 11, and the axle seats 55 are welded to the seat 1 bracket , the rotating shaft 52 is arranged in each shaft seat 55, and also includes the U-shaped rotating frame 2 arranged outside the backrest 12 and the first reduction motor 51 and the block cap 6 fixedly installed on both sides of the seat cushion 11 respectively. The motor 51 is connected, and the other end is fixedly connected with the rotating disk 53 arranged in the cap 6, and the first microswitch 71 and the second microswitch 72 are arranged in the cap 6, and the rotating disk 53 is fixedly connected with a Trigger the contact of the first micro switch 71 and the second micro switch 72, when the contact triggers the first micro switch 71, as figure 2 As shown, the rotating frame 2 is in a ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com