On-machine measuring method for wall thickness of complex thin-wall structure part

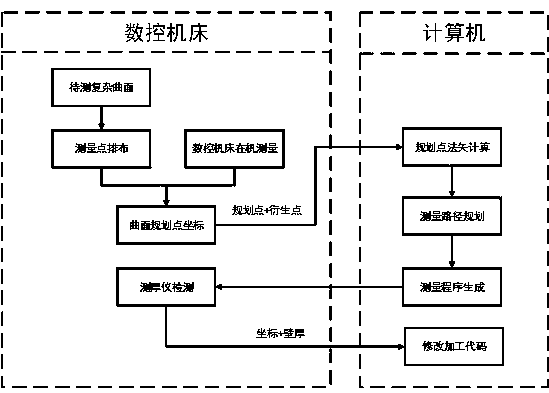

A thin-walled structure and measurement method technology, applied in the direction of measurement/indicating equipment, metal processing machinery parts, metal processing equipment, etc., can solve problems such as difficult to obtain measurement data, affect measurement accuracy, and scrap parts after processing, and achieve measurement efficiency High, increase adaptability, reduce the effect of raw material cost

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0039] Embodiments of the present invention will be further described in detail below in conjunction with the accompanying drawings.

[0040] Step 1. After the CNC milling machine rough-machines the free-form thin-walled workpiece, call the automatic tool change program of the CNC milling machine, remove the milling cutter used for processing, and replace it with a contact probe;

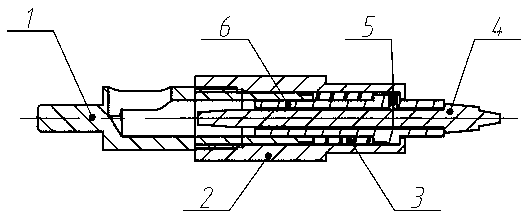

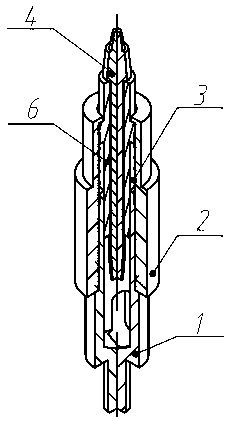

[0041] Step 2: Use the touch probe to detect the planned points of the curved surface planned by the computer, and the actual measurement coordinates of the planned points on the curved surface are fed back to the computer in real time by the machine tool. Among them, the contact probe is a device equipped with machine tools, see attached Figure 9, the planning points on the surface are generated by the special software on the computer, and these planning points are evenly arranged on the surface to be measured. Then calculate the actual normal vector of the surface to be measured according to the...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com