Fully-automatic powder spreading device

A powder spreading device and fully automatic technology, which is applied in the field of fully automatic powder spreading devices, can solve the problems of manual addition, low production efficiency, uneven powder adhesion, etc., and achieve the effects of improving efficiency, uniform powder spreading, and saving manpower and labor

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0014] The specific implementation manners of the present invention will be further described below in conjunction with the drawings and examples.

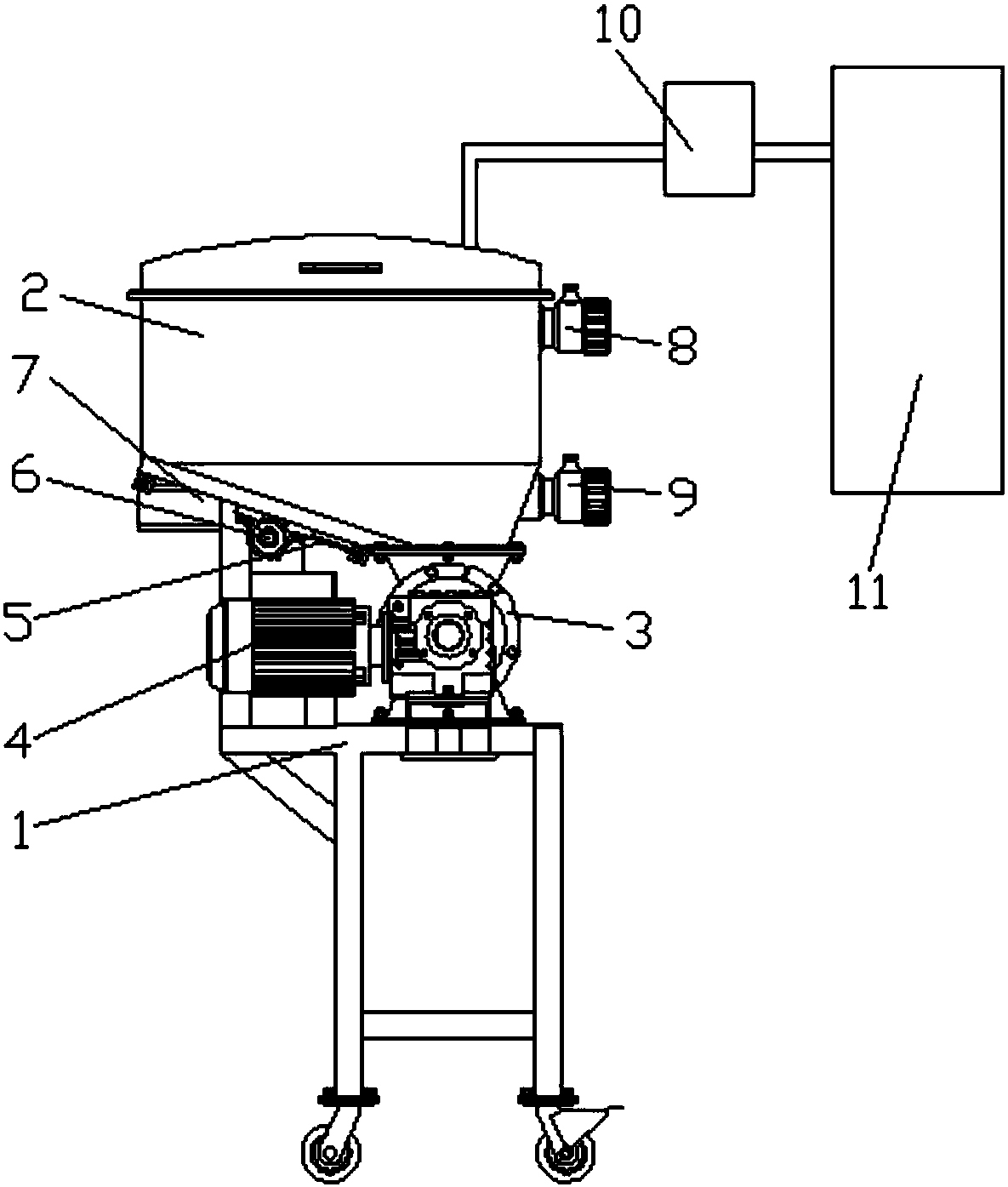

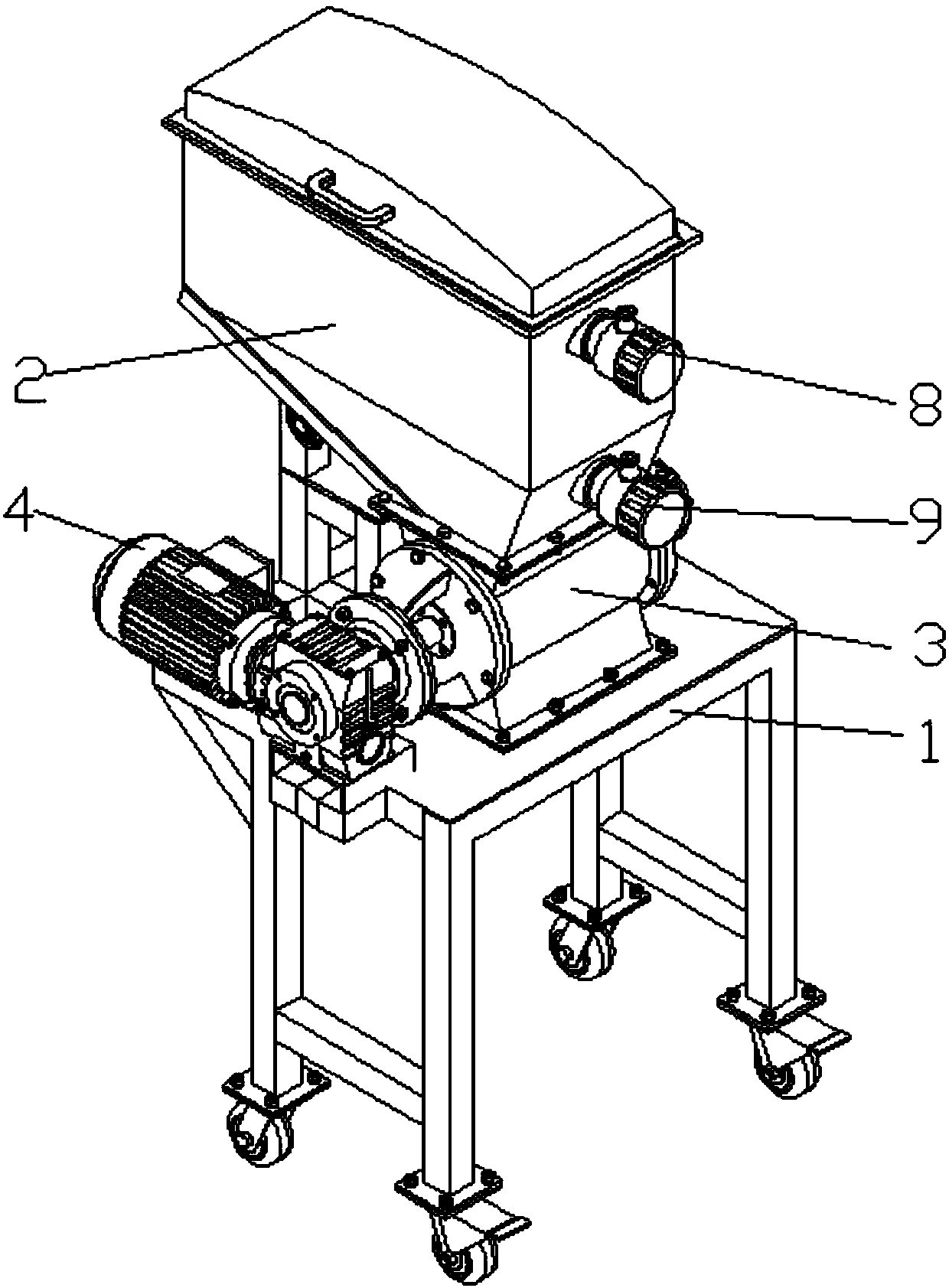

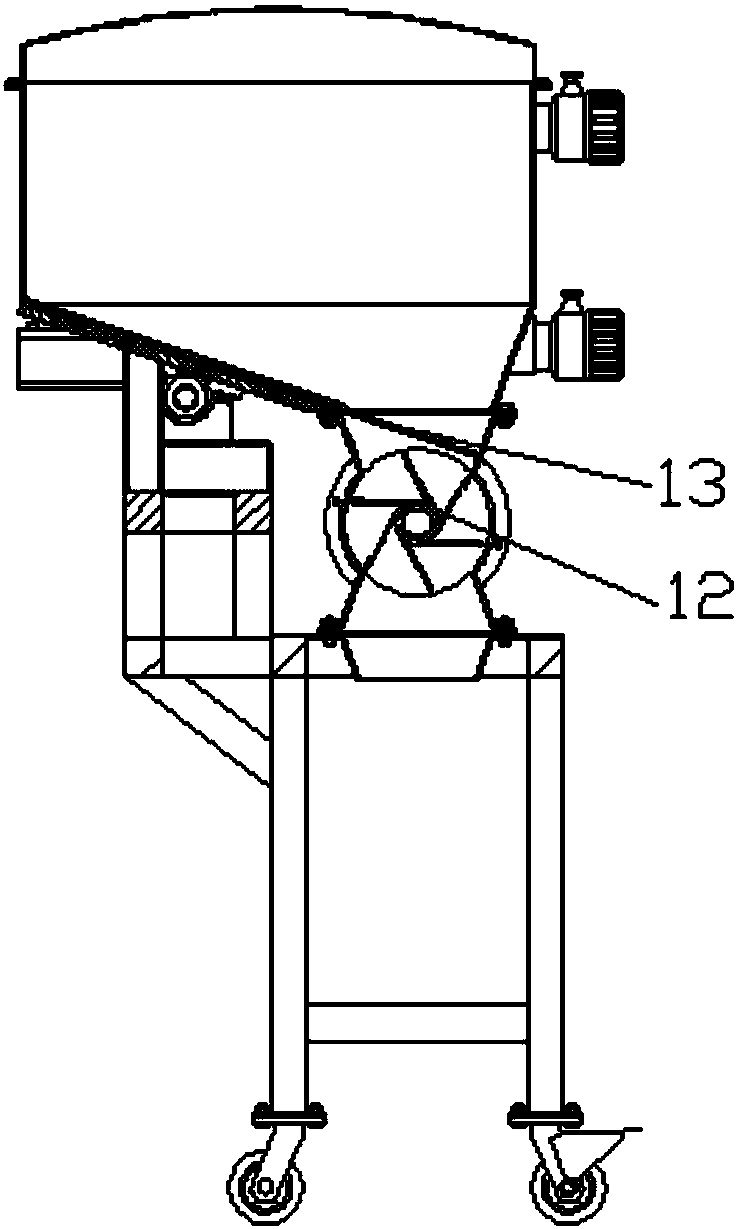

[0015] Such as Figure 1 to Figure 3 As shown, the fully automatic powder spreading device of the present invention includes a frame 1, a feed bin 2, an impeller feeder 3, a powder delivery pump 10, and a powder bin 11, and the frame 1 is equipped with a feed bin 2, so The bottom outlet of the silo 2 is equipped with an impeller feeder 2. There are 6 elastic impellers 12 uniformly distributed along the circumference in the impeller feeder 2. Silicone rubber gaskets are stuck on the impeller blades, and there is no gap between the impeller blades and the shell. seam fit, can be effectively sealed, the impeller shaft of the impeller feeder 3 is connected with the output shaft of the first reduction motor 4; The adjustable gate valve device 5 includes a gate 13, a gear, and a rack. The gate 13 is arranged inside the silo and is fixe...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com