Casual mutton product and manufacturing method thereof

A production method and mutton technology, which are used in food ingredients as taste improvers, dry preservation of meat/fish, and chemical preservation of meat/fish, etc., can solve the problem of single type, inability to improve, and poor quality and flavor of leisure mutton products and other problems, to achieve the effect of improving the extraction rate, extending the shelf life of the product, and increasing the added value of the product

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

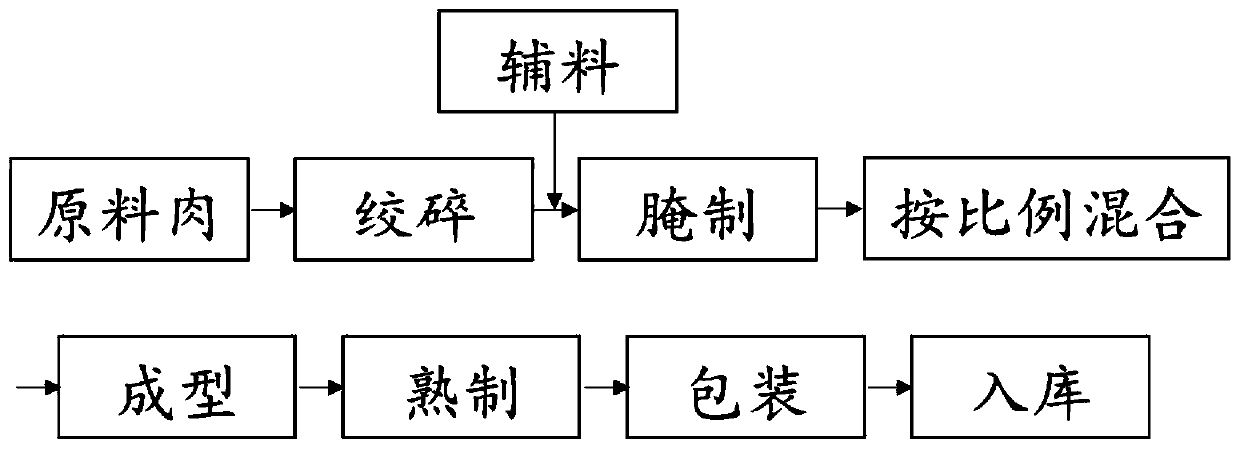

Method used

Image

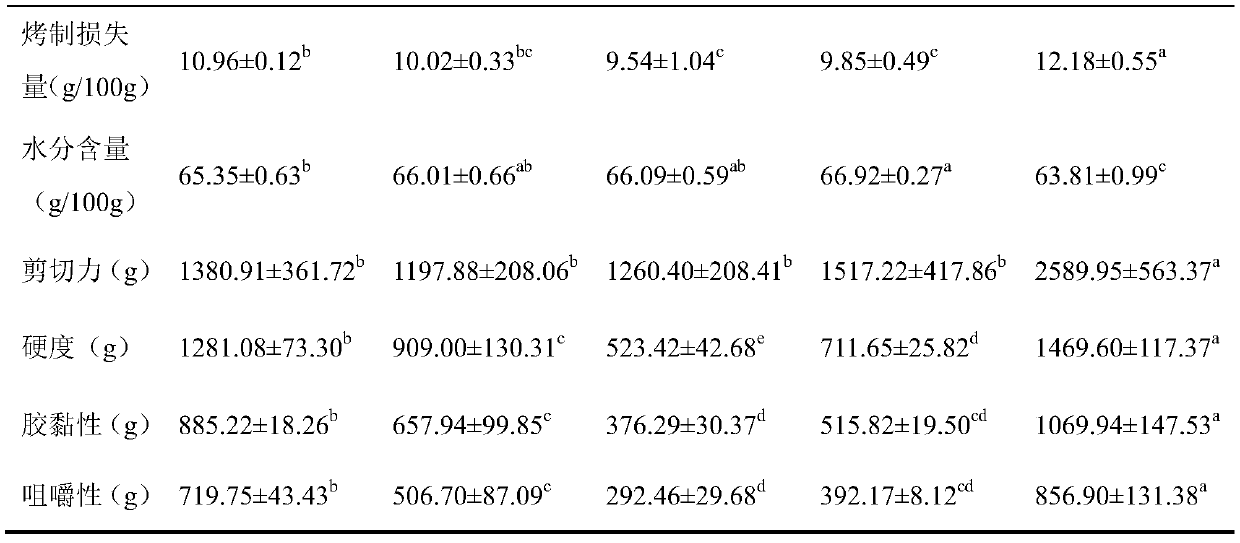

Examples

Embodiment 1

[0035] A leisure mutton product, comprising 50 parts by weight of mutton, 15 parts of white chocolate, 5 parts of peanuts, 5 parts of walnuts, 0.5 parts of salt, 1 part of cooking wine, 0.5 parts of white wine, and 0.5 parts of chicken essence , 0.3 parts of gum arabic, 0.1 parts of black pepper, 0.1 parts of scallions, 0.1 parts of ginger powder, 0.1 parts of white sugar, 0.5 parts of sesame oil, 0.1 parts of bay leaf powder, 0.1 parts of cinnamon powder, 0.1 parts of of fennel powder.

[0036] The preparation method of described recreational mutton product, comprises the following steps:

[0037] S1, mince the mutton in the above parts by weight into meat filling, then add gum arabic and form it into a gel to obtain the mutton filling;

[0038] S2. Add the above-mentioned salt, cooking wine, white wine, chicken essence, black pepper, green onion, ginger powder, white sugar, sesame oil, bay leaf powder, cinnamon powder, and fennel powder in the above weight parts to the mutt...

Embodiment 2

[0050] A leisure mutton product, comprising 50 parts by weight of mutton, 20 parts of white chocolate, 10 parts of peanuts, 10 parts of walnuts, 1 part of table salt, 2 parts of cooking wine, 1 part of white wine, and 1 part of chicken essence , 0.5 parts of gum arabic, 0.5 parts of black pepper, 0.5 parts of scallions, 0.5 parts of ginger powder, 0.5 parts of white sugar, 1 part of sesame oil, 0.5 parts of bay leaf powder, 0.5 parts of cinnamon powder, 0.5 parts of fennel powder.

[0051] A method for making leisure mutton products, comprising the following steps:

[0052] S1, mince the mutton in the above parts by weight into meat filling, then add gum arabic and form it into a gel to obtain the mutton filling;

[0053]S2. Add the above-mentioned salt, cooking wine, white wine, chicken essence, black pepper, green onion, ginger powder, white sugar, sesame oil, bay leaf powder, cinnamon powder, and fennel powder in the above weight parts to the mutton stuffing in S1, and the...

Embodiment 3

[0065] A leisure mutton product, comprising 50 parts by weight of mutton, 20 parts of white chocolate, 10 parts of peanuts, 10 parts of walnuts, 1 part of table salt, 2 parts of cooking wine, 1 part of white wine, and 1 part of chicken essence , 1 part of gum arabic, 0.5 parts of black pepper, 0.5 parts of scallions, 0.5 parts of ginger powder, 0.5 parts of white sugar, 1 part of sesame oil, 0.5 parts of bay leaf powder, 0.5 parts of cinnamon powder, 0.5 parts of fennel powder.

[0066] A method for making leisure mutton products, comprising the following steps:

[0067] S1, mince the mutton in the above parts by weight into meat filling, then add gum arabic and form it into a gel to obtain the mutton filling;

[0068] S2. Add the above-mentioned salt, cooking wine, white wine, chicken essence, black pepper, green onion, ginger powder, white sugar, sesame oil, bay leaf powder, cinnamon powder, and fennel powder in the above weight parts to the mutton stuffing in S1, and then ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Diameter | aaaaa | aaaaa |

| Thickness | aaaaa | aaaaa |

| Diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com