An Axial Diaphragm Coupling

A diaphragm coupling and diaphragm technology, applied in the direction of couplings, elastic couplings, mechanical equipment, etc., can solve the problem that the angular displacement of compensation cannot meet the needs, the structure is not very reasonable, the main and driven shafts Problems such as synchronous bearing vulnerable

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

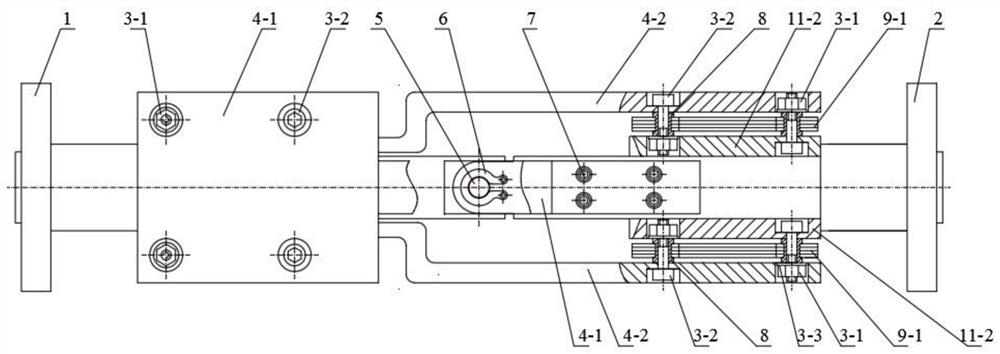

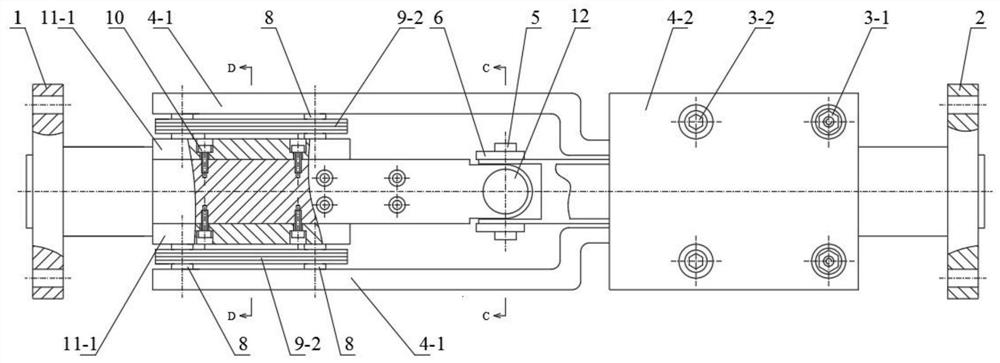

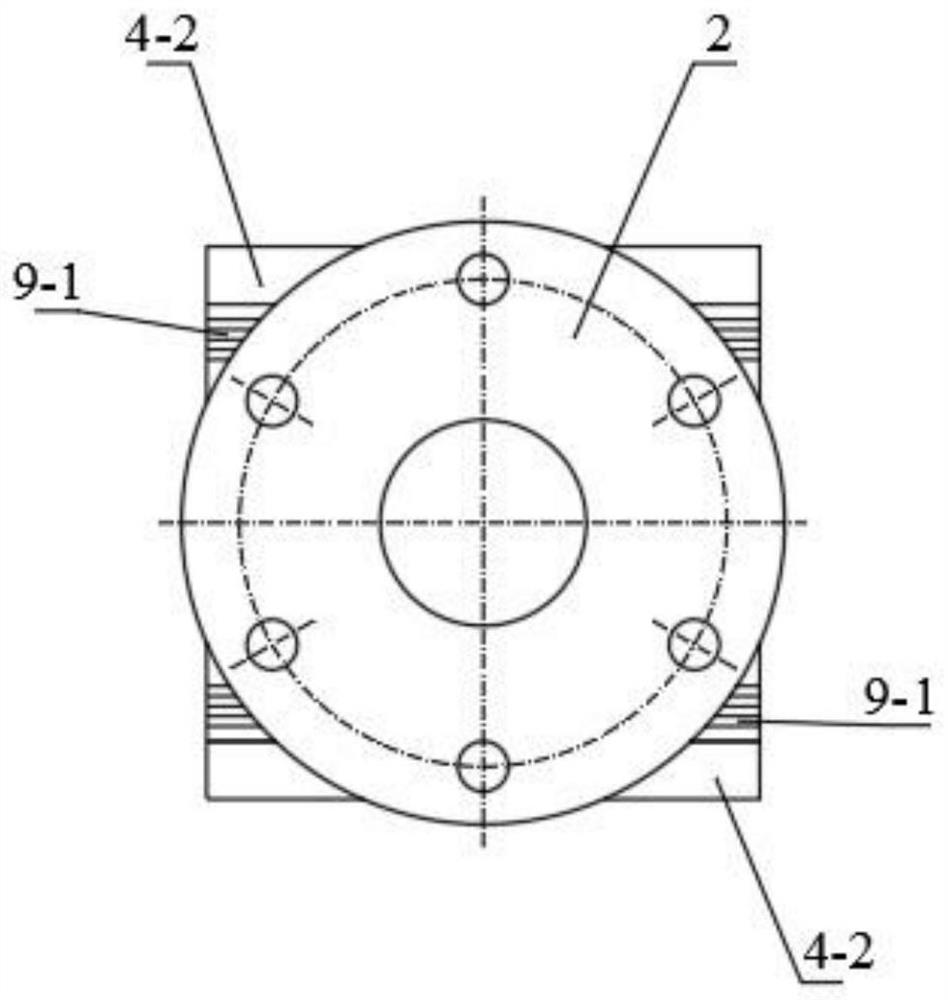

[0030] Embodiment 1, reference figure 1 , figure 2 , image 3 , Figure 4 , Figure 5 , Figure 6 , Figure 7 , Figure 8 , Figure 9 , Figure 10 , Figure 11 , Figure 12 , Figure 13 , Figure 14 , Figure 15 , Figure 16 , Figure 17 , Figure 18 , Figure 19 , Figure 20 , Figure 21 , Figure 22 , Figure 23 , Figure 24 . It can be seen from the accompanying drawings that an axial diaphragm coupling is composed of the first half-shaft section 1, the second half-shaft section 2, the diaphragm group connecting bolts and nuts 3-1, and the diaphragm group connecting bolts 3-2 , Diaphragm group connection bolt gasket 3-3, first diaphragm connection plate 4-1, second diaphragm connection plate 4-2, thin universal pin 5, thin universal pin spring retaining ring 6, diaphragm connection Plate fixing screw 7, diaphragm group fixing sleeve 8, first diaphragm group 9-1, second diaphragm group 9-2, diaphragm group fixing plate fixing screw 10, first diaphrag...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com