Stacked suspended ceiling installation system and installation method thereof

An installation system and stage crane technology, which is applied in ceilings, building components, shockproof, etc., can solve problems such as difficult installation, fire safety hazards, and affecting ground operations, so as to save time and cost, reduce welding operations, and avoid suspended ceilings shaking effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

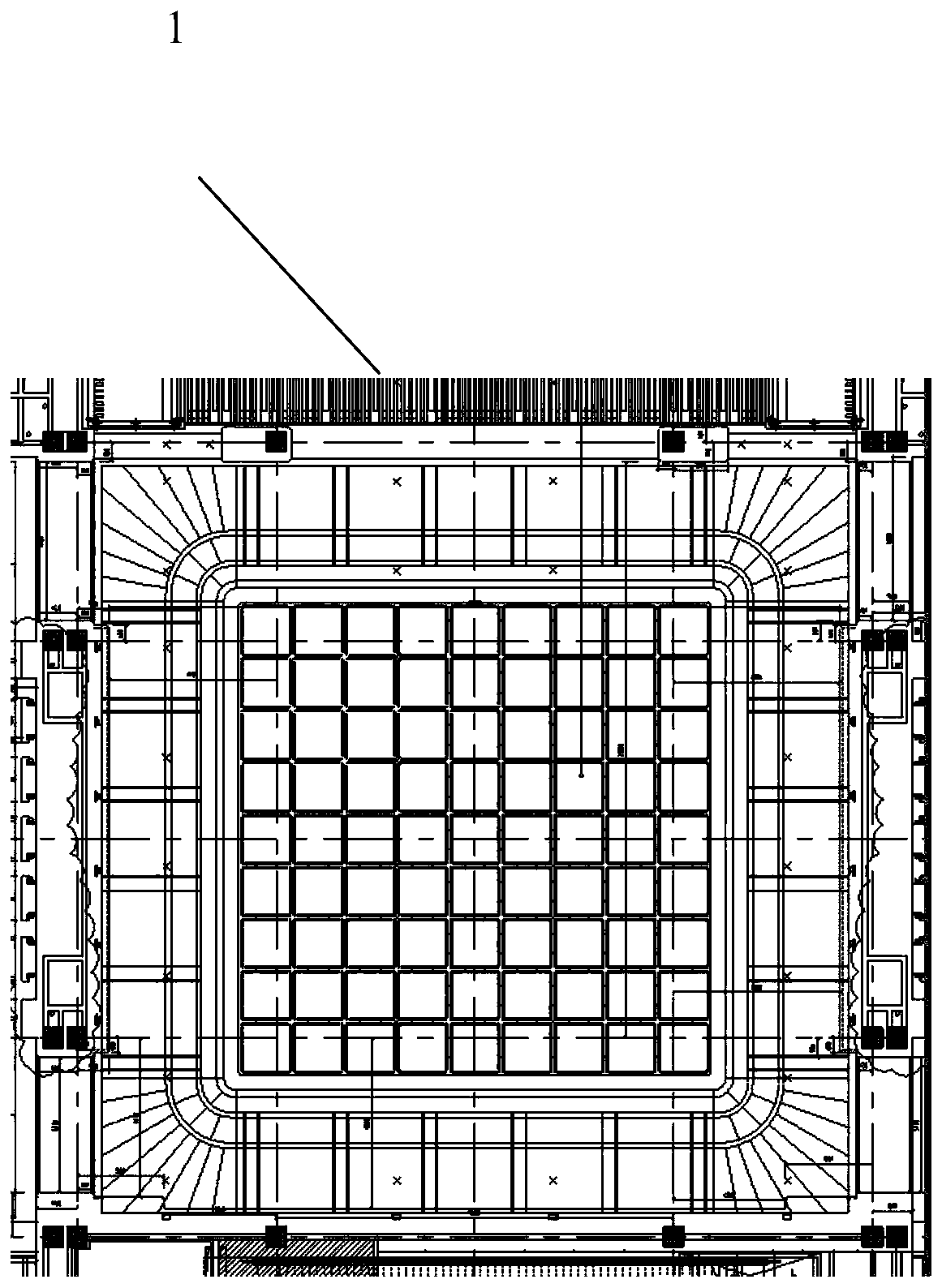

[0060] figure 1 It is the overall schematic diagram of the stacked ceiling installation system in this embodiment.

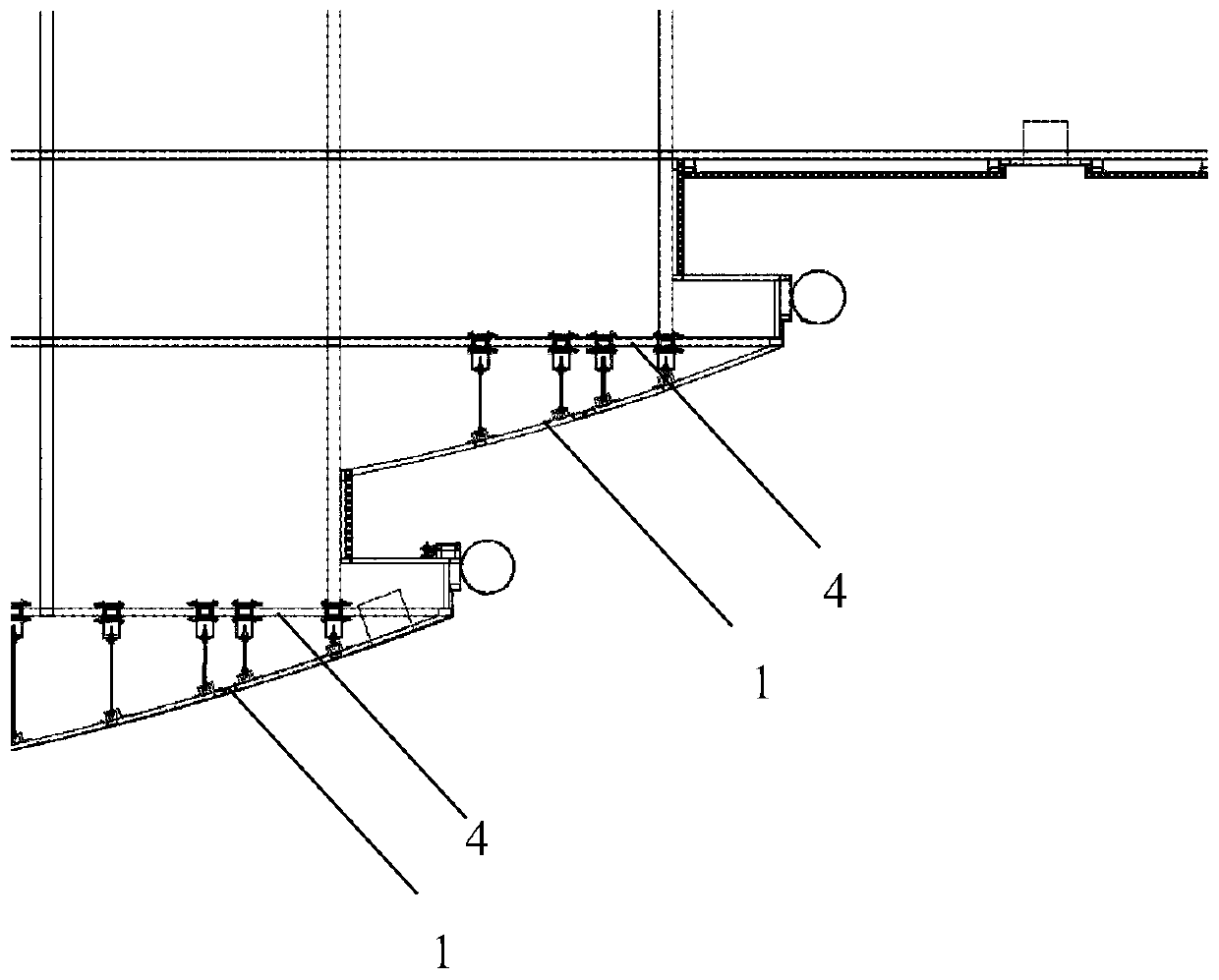

[0061] figure 2 It is a schematic diagram of the installation structure of the stacked ceiling installation system in this embodiment.

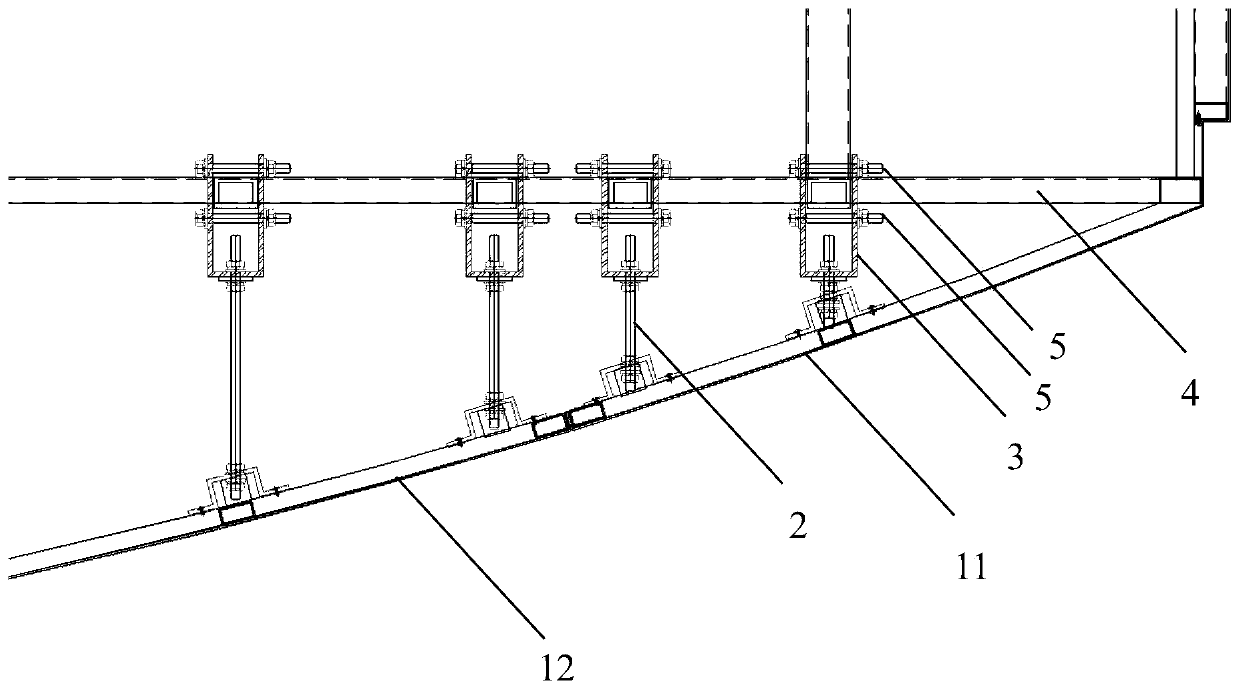

[0062] image 3 It is a partial installation structure diagram of the stacked ceiling installation system in the embodiment of the present invention.

[0063] Such as figure 1 , figure 2 , image 3 As shown, a stacked ceiling installation system provided in this embodiment is installed on the main steel frame of the ceiling. The stacked integral ceiling surrounds and installs a central flat ceiling, and has a double-layer structure with four corners forming an arch effect. It has arc-shaped boards, and each layer of hanging boards is in the shape of a ring as a whole, which is very difficult to install. In this embodiment, the total size of the white copper plate decorative ceiling is 30100mm*30100mm, which is divided ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com