Copper powder preparation device and preparation method thereof

A preparation device and copper powder technology, applied in the field of electrolytic copper, can solve the problems of inconsistent thickness of metal powder, difficulty in obtaining fine and uniform powder, inconsistent powder scraping time, etc., to avoid different particle size and thickness, improve production efficiency, and powder scraping speed controllable effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

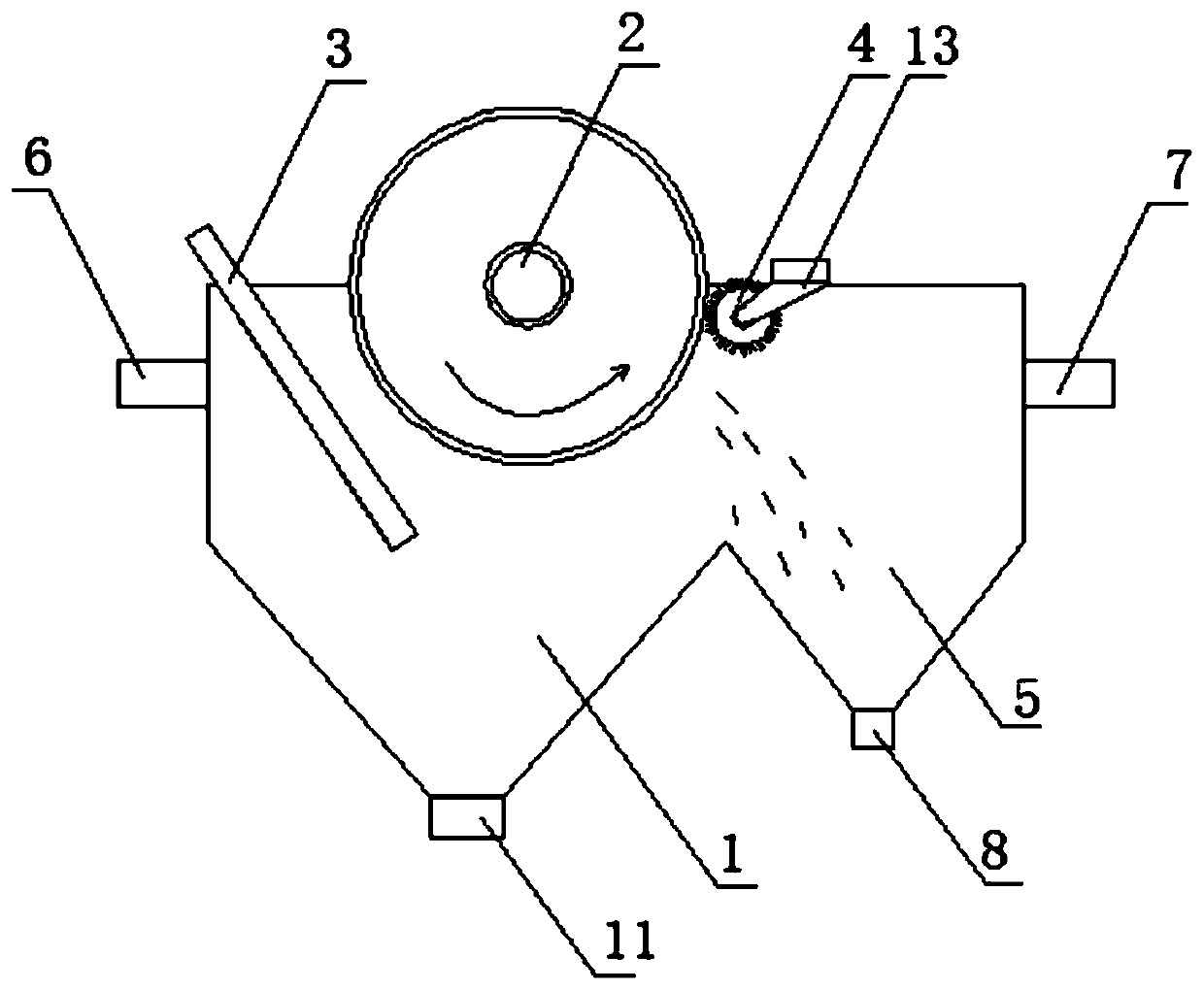

[0024] Such as figure 1 As shown, this embodiment provides a copper powder preparation device, including an electrolytic reaction tank 1 and a copper cathode drum 2 arranged in the electrolytic reaction tank 1, and the electrolytic reaction tank 1 on the side opposite to the copper cathode drum 2 A soluble copper anode plate 3 is arranged in the center, a copper powder flushing device 4 is arranged on the opposite side of the copper cathode drum 2, and a copper powder flushing device 4 is arranged below the side close to the copper powder flushing device 4, which is connected to the electrolytic reaction tank. 1 connected copper powder collection tank 5, one side of the electrolytic reaction tank 1 is provided with a liquid inlet 6, and one side of the copper powder collection tank 5 is provided with a liquid outlet 7, in the copper powder collection tank 5 The lower end is also provided with a copper powder collection port 8.

[0025] pass figure 1 It can be seen that the s...

Embodiment 2

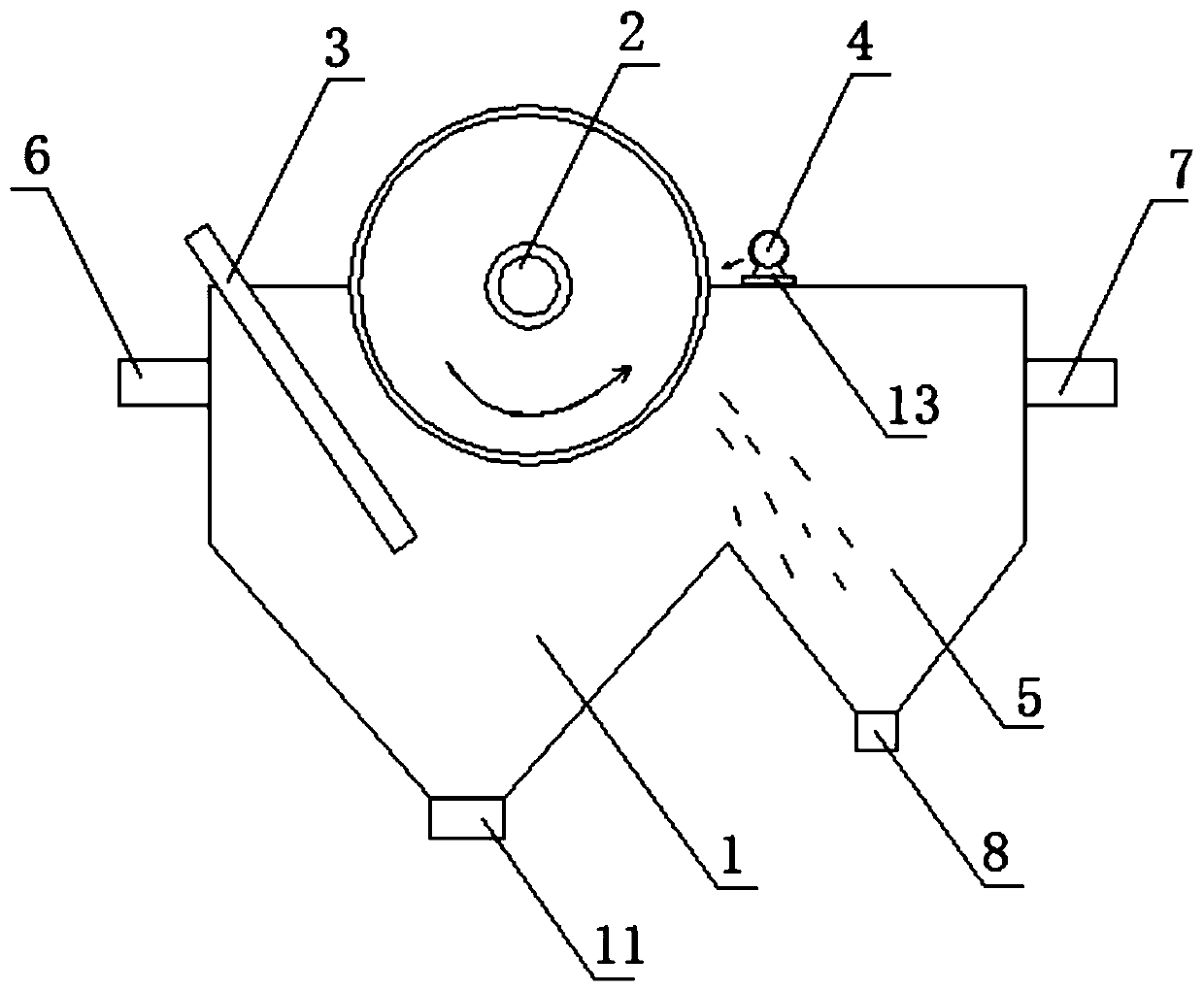

[0029] Such as figure 2 As shown, the difference between this embodiment and Embodiment 1 is that the copper powder flushing device 4 is a water spray pipe, and the electrolyte solution is sprayed out circularly through the water spray pipe, and the impact force of the high-pressure solution is used to rinse the copper on the surface of the copper cathode drum 2 Powder makes it sink in the copper powder collecting tank 5, can reach the effect of embodiment 1 equally.

Embodiment 3

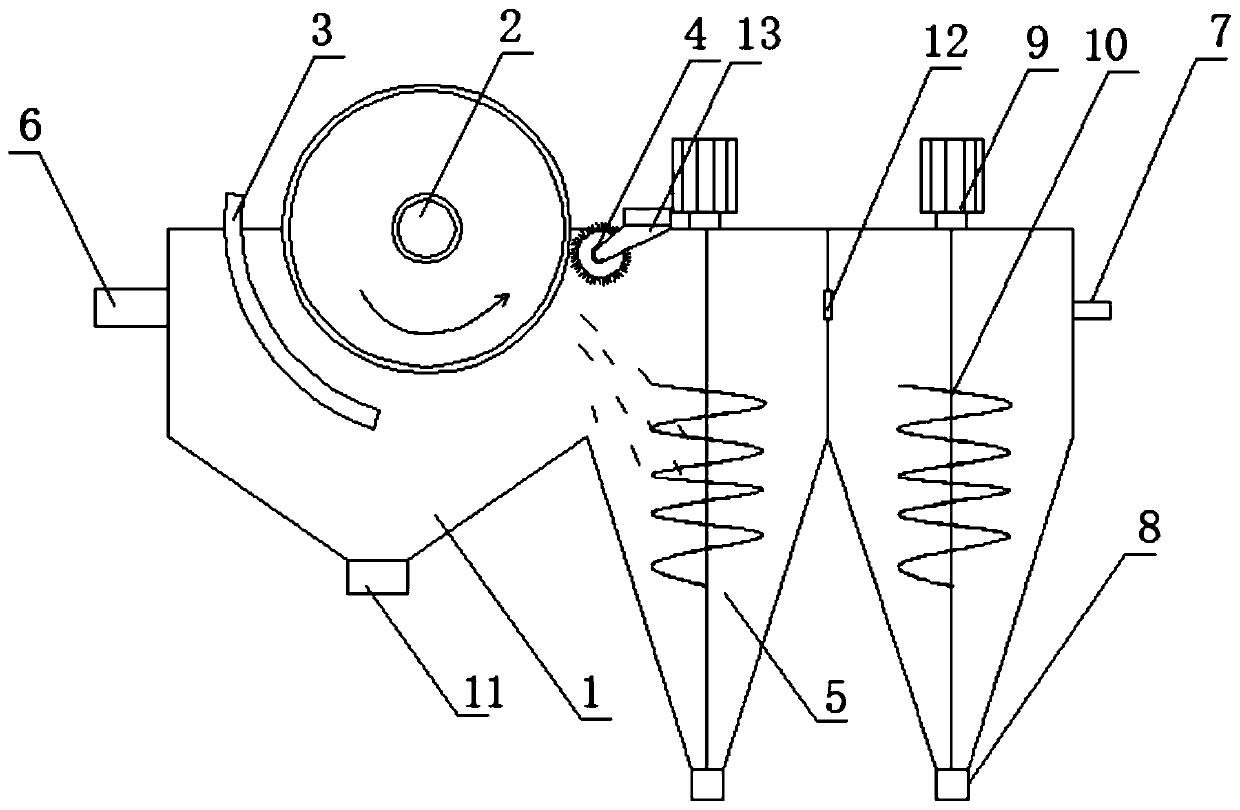

[0031] Such as image 3 As shown, the difference between this embodiment and Embodiment 1 is that the soluble copper anode plate 3 is an arc-shaped plate opposite to the copper cathode drum 2, which further increases the soluble copper anode plate 3 and the copper cathode drum 2. Between the effective area, in order to facilitate the collection of copper powder, the copper powder collection tank 5 is made of a plurality of conical tanks arranged in parallel, the lower end of which is funnel-shaped, and in each of the conical tanks is provided with The swirl paddle 10 for realizing swirl flow precipitation is also provided with a variable speed motor 9 for driving the swirl paddle 10 to rotate at the upper end of the copper powder collection tank 5 . During specific implementation, two adjacent tapered tanks are separated by a partition, and a strip-shaped mouth 12 for electrolyte circulation is provided on the partition. In order to facilitate swirl precipitation, the strip-sh...

PUM

| Property | Measurement | Unit |

|---|---|---|

| bulk density | aaaaa | aaaaa |

| density | aaaaa | aaaaa |

| specific surface area | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com