A high-efficiency oil-immersed transformer with fast exhaust

An oil-immersed transformer, high-efficiency technology, applied in the direction of transformer/inductor cooling, etc., can solve problems such as low work efficiency, reduced purity, and reduced oil insulation, and achieve the effects of improving work efficiency, shortening power outage time, and improving purity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

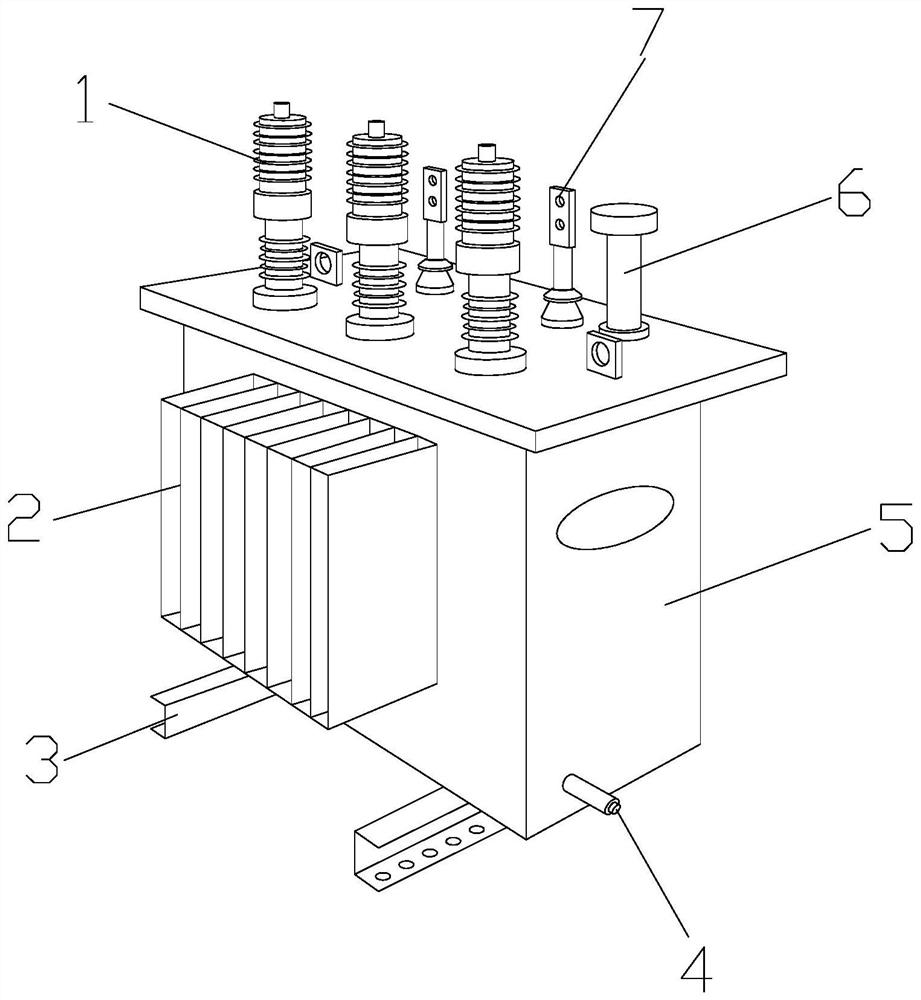

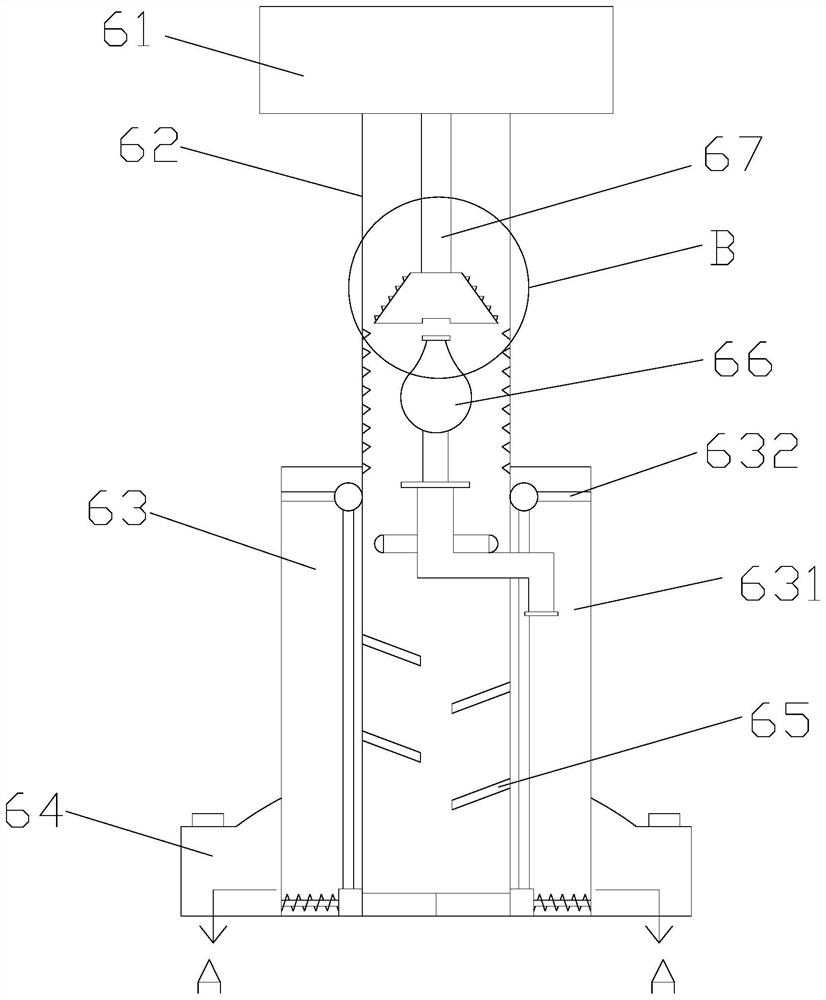

[0026]SeeFigure 1-Figure 2 , The present invention provides a high-efficiency oil-immersed transformer that can quickly exhaust gas. Its structure includes high-voltage terminal 1, heat sink 2, fixed base 3, oil drain pipe 4, fuel tank body 5, oil filling pipe 6, low-voltage connection terminal 7, and The fuel tank body 5 has a rectangular structure, the fixed base 3 is provided with two fixed bases which are welded to the left and right ends of the bottom surface of the fuel tank body 5, the heat dissipation plate 2 is located between the front and rear surfaces of the fuel tank body 5, and the high-voltage terminal 1 is provided with Three are respectively located on the upper surface of the tank body 5. The low-voltage terminal 7 is installed behind the high-voltage terminal 1 and parallel to the high-voltage terminal 1, the drain pipe 4 is welded to the bottom of the right side of the fuel tank body 5. 6 Vertically installed at the upper right corner of the upper surface of the ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com