Method for manufacturing photomask, inspection method, and inspection device

An inspection method and inspection device technology, applied in the field of photomasks, can solve the problems of uniform film surface shape, insufficient flatness of worktable, substrate deflection, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment approach 1

[0117] The manufacturing method of the photomask of this invention has the following process.

[0118] Preparation of Photomask Blanks

[0119] In the present invention, drawing for forming a photomask based on a pattern designed based on a desired device is performed on a photomask blank formed on a main surface of a substrate. One or more thin films, and photoresist films are obtained. Therefore, a photomask blank in which the above-mentioned thin film and photoresist film were formed on one main surface of the substrate was prepared.

[0120] As the photomask blank to be prepared, a known photomask blank can be used.

[0121] As the substrate, a transparent substrate such as quartz glass can be used. Although the size and thickness are not limited, as the substrate used in the manufacture of a device for a display device, a substrate having a side of 300 mm to 1800 mm and a thickness of about 5 to 15 mm can be used.

[0122] In this application, in addition to the subst...

Embodiment approach 2

[0258]

[0259] As described above, according to the present invention, it is possible to obtain a photomask capable of extremely high coordinate accuracy of a pattern formed on a workpiece.

[0260] In addition, when such a photomask is inspected before shipment, it is most desirable to inspect in consideration of the difference between the photomask placed on the inspection device and the photomask held on the exposure device.

[0261] Therefore, the inventors found the necessity of a new inspection method.

[0262] VII Process of Obtaining Pattern Coordinate Data L

[0263] The patterned photomask was placed on the table of the coordinate inspection apparatus so that the film surface (pattern formation surface) was on the upper side, and coordinate measurement was performed. The data obtained here are assumed to be pattern coordinate data L.

[0264] Here, it is preferable to perform coordinate measurement by measuring the coordinates of the mark pattern previously form...

Embodiment

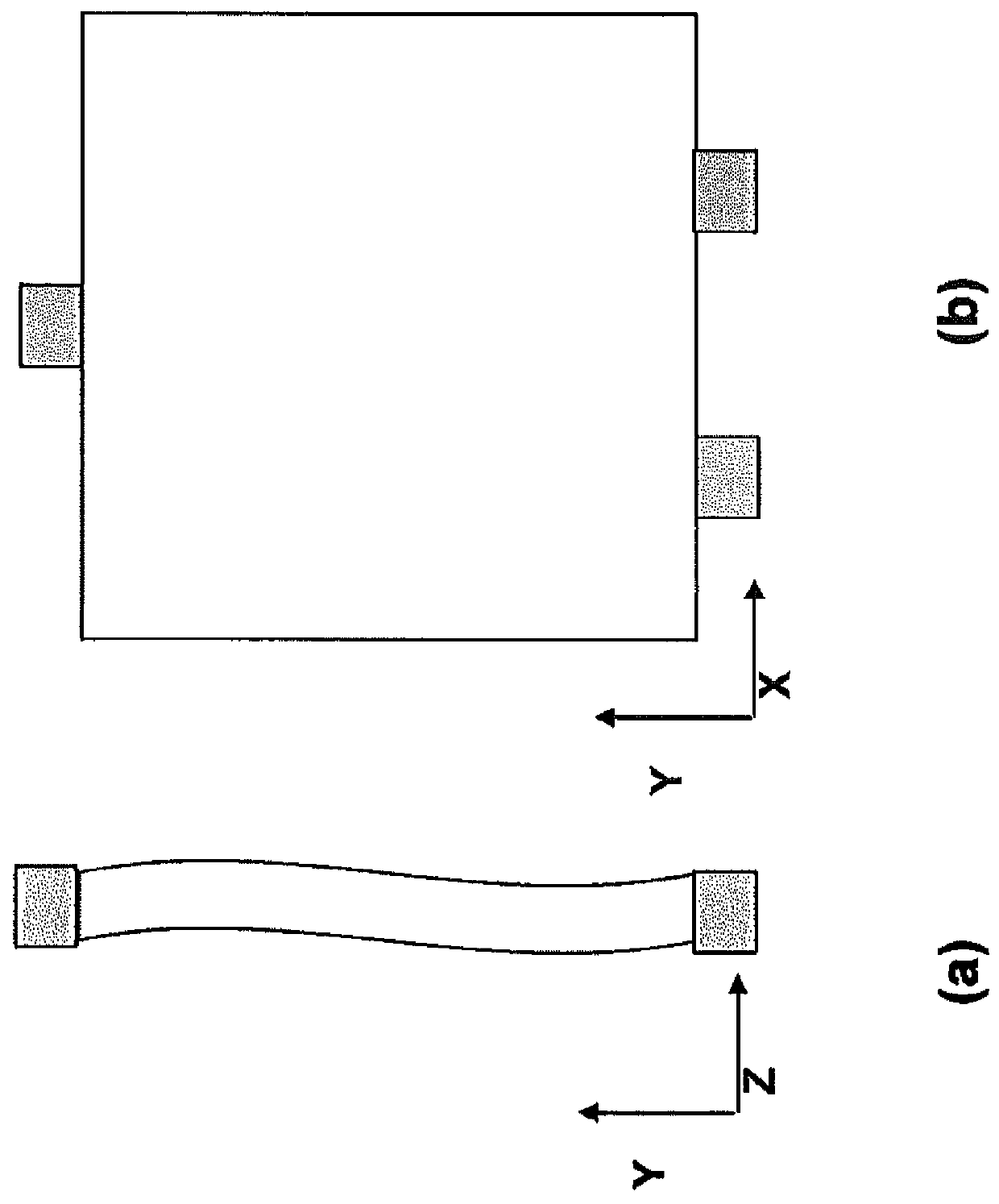

[0305] use Figure 12 The schematic diagram shown shows the effect of the invention based on the photomask manufacturing method (drawing process) of the present invention.

[0306] Here, the result obtained by simulation is shown in the case where a pattern for transfer is drawn on a substrate (photomask blank) having a specific substrate surface shape (substrate surface shape data B), where How does the coordinate accuracy of the transfer pattern change when it reaches the inside of the exposure device (as a result, how does the coordinate accuracy of the pattern formed on the transfer target change).

[0307] First, a specific test pattern was drawn on the above-mentioned photomask blank using a drawing device. In the test photomask blank used here, a light-shielding film and a positive photoresist film were formed on the main surface of a quartz substrate having a size of 800 mm×920 mm.

[0308] As the pattern design data used here, a test pattern including a cross patter...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com