Preparation method of bendiocarb intermediate and active ingredient

A technology of dicarbacarb and intermediates, which is applied in the field of preparation of dicarbacarb technical materials, can solve the problems of equipment design and industrial application difficulties, long operation time, long reaction time, etc., and achieve shortened reaction time, simple processing, and high reaction time. The effect of improving efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

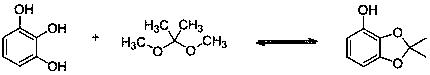

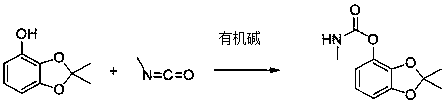

Embodiment 1

[0032]360ml of xylene, 84g (0.659mol) of pyrogallic acid and 101g (0.962mol) of 2,2-di Methoxypropane, dissolve 176g (1.673mol) 2,2-dimethoxypropane in 100ml xylene, put the 2,2-dimethoxypropane solution in a constant pressure funnel, and gradually Raise the temperature, control the reaction temperature to 102°C and carry out the reaction for 1-1.5 hours, while distilling off the light components; Evaporate the light components while adding dropwise. After about 4-5 hours, the dropwise addition is completed, and the light components collected in the water separator are released continuously, so as not to form reflux. When it is detected that the unconverted rate of pyrogallic acid is less than 2.2wt%, the reaction solution is cooled to obtain 595.1g intermediate 2,2-dimethyl-4-hydroxyl-1,3-benzodioxol feed solution, The content is 17.5wt%, and the yield is 95.1% based on pyrogallic acid. Add 50g of 14wt% sodium hydroxide solution to the distilled light component, stir and wa...

Embodiment 2

[0035] 300ml of xylene, 84g (0.659mol) of pyrogallic acid and 81g (0.769mol) of 2,2-di For methoxypropane, dissolve 222.5g (2.115mol) 2,2-dimethoxypropane in 120ml xylene, fill the 2,2-dimethoxypropane solution in a constant pressure funnel, and stir under magnetic force Gradually raise the temperature, control the reaction temperature to 102°C for 1-1.5 hours, and distill off the light components at the same time; Evaporate the light components while adding dropwise. After about 4.5 hours, the dropwise addition is completed, and the light components collected in the water separator are released continuously, so as not to form reflux. When it is detected that the unconverted rate of pyrogallic acid is less than 2.2wt%, the reaction is stopped, and the temperature is lowered to obtain 617.3g of intermediate 2,2-dimethyl-4-hydroxyl-1,3-benzodioxol feed solution, the content It is 16.8wt%, and the yield is 94.7% based on pyrogallic acid. Add 50g of 10wt% sodium hydroxide soluti...

Embodiment 3

[0038] Put 500ml xylene, 84g (0.659mol) pyrogallic acid and 141.6g (1.346mol) 2,2 - Dimethoxypropane, dissolve 151.7g (1.442mol) 2,2-dimethoxypropane in 90ml xylene, put the 2,2-dimethoxypropane solution in a constant pressure funnel, and stir it magnetically Gradually raise the temperature, control the reaction temperature to 102°C for 1-1.5 hours, and distill off the light components at the same time; when the methanol no longer comes out, drop the 2,2-dimethoxypropane solution in the constant pressure dropping funnel, Evaporate the light components while adding dropwise. After the dropwise addition is completed in about 5 hours, the light components collected in the water separator are continuously released to prevent reflux. When it is detected that the unconverted rate of pyrogallic acid is less than 2.2wt%, the reaction is stopped, and the temperature is lowered to obtain 627.3g of intermediate 2,2-dimethyl-4-hydroxyl-1,3-benzodioxol feed solution. It is 16.5wt%, and th...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com