Prefabricated assembled type wall pouring forming positioning device and using method

A prefabricated assembly and positioning device technology, applied in the direction of ceramic molding machines, manufacturing tools, etc., can solve the problems of bellows displacement, affecting the accuracy of the hole for inserting ribs, etc., to achieve easy storage and movement, convenient and quick disassembly, and simple and convenient operation Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

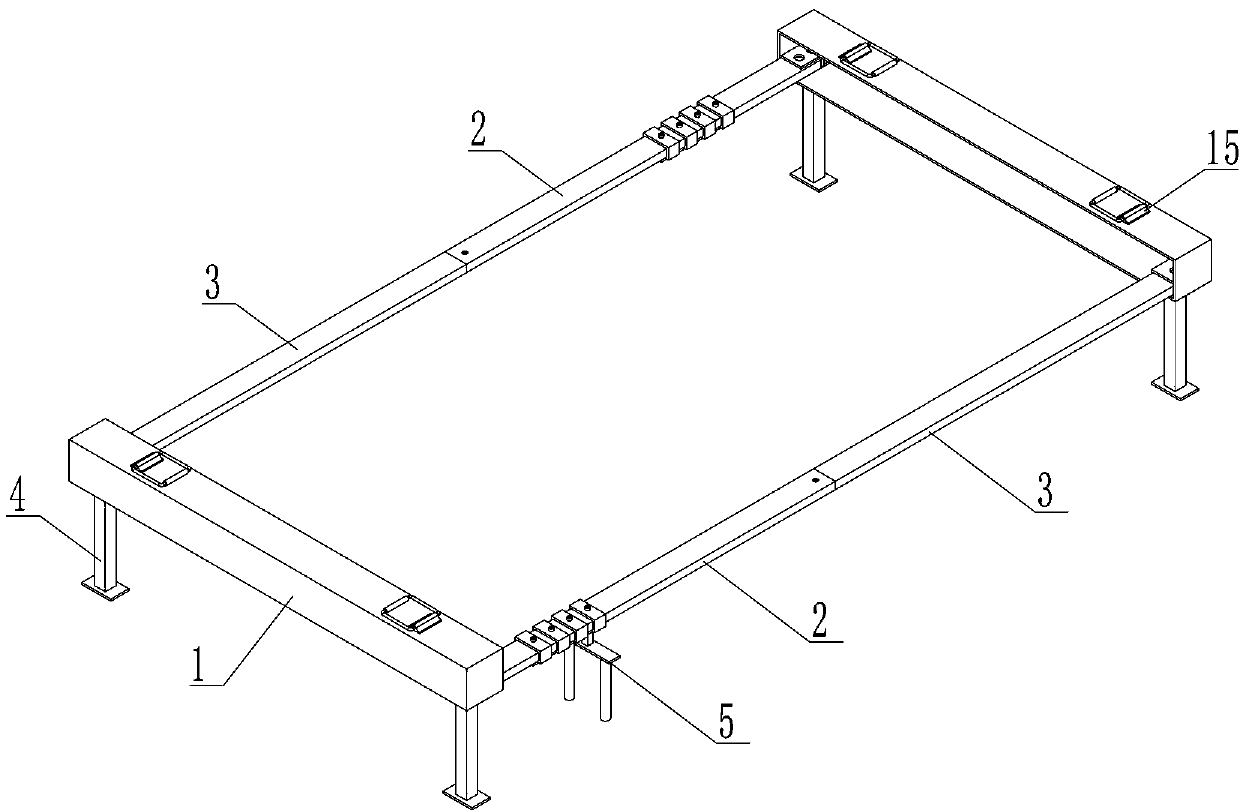

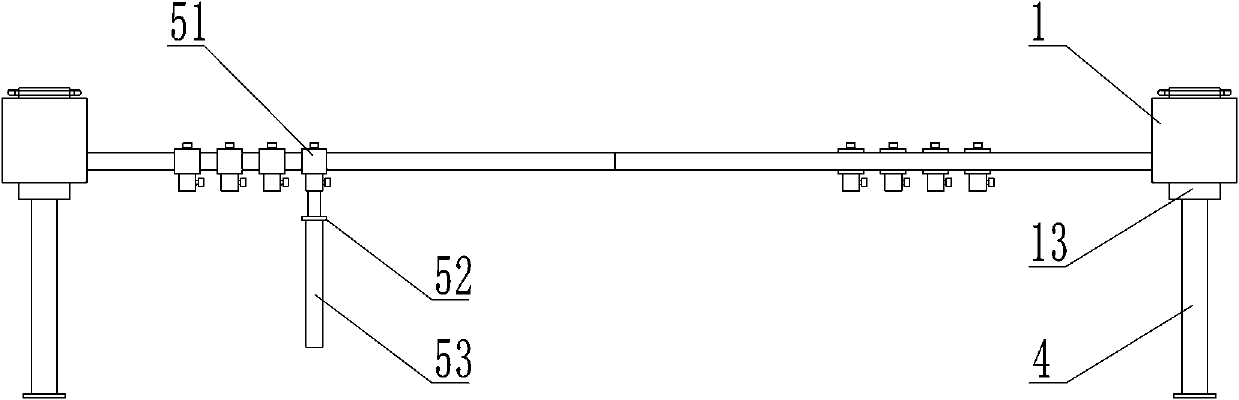

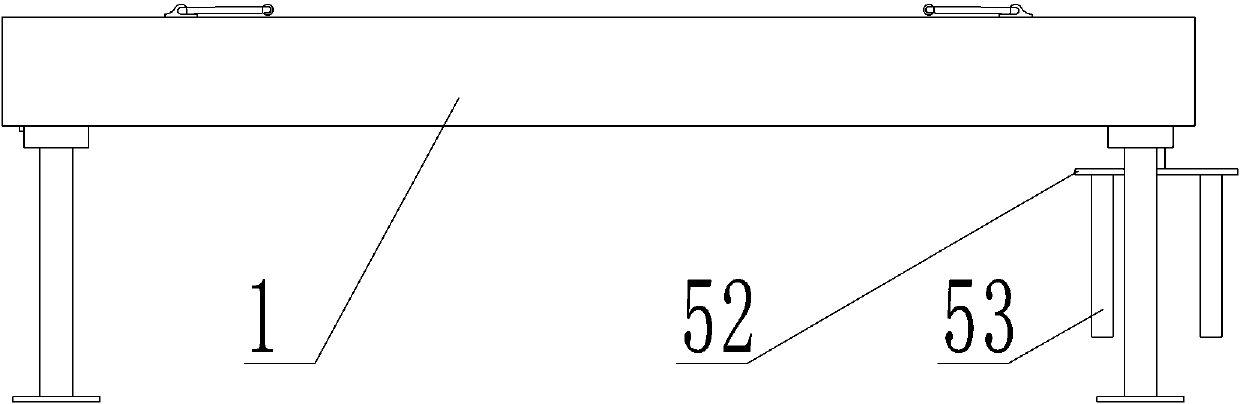

[0057] Such as Figure 1~Figure 12 Among them, a prefabricated assembly type wall casting and forming positioning device, which includes a receiving beam 1, a folding beam 2, an insertion beam 3, a supporting beam 4 and a positioning mechanism 5; the folding beam 2 is movably connected to one end of the receiving beam 1 , the plug-in beam 3 is plugged with the accommodation beam 1 and the folding beam 2, the support beam 4 is connected with the accommodation beam 1, and the positioning mechanism 5 is slidingly matched with the folding beam 2 and the insertion beam 3; the folding beam 2 can be folded and accommodated in the accommodation In the beam 1, the insertion beam 3, the support beam 4 and the positioning mechanism 5 can be accommodated in the accommodation beam 1 after being disassembled. The structure is simple, the folding beam 2 is flexibly connected to the receiving beam 1, the plug-in beam 3 is plugged with the folding beam 2 and the receiving beam 1 to form a fram...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com