Sorting machine for warehouse logistics

A technology of warehousing logistics and sorting machine, applied in the field of warehousing and logistics, can solve the problems of poor use flexibility and reduce labor intensity of workers, and achieve the effect of facilitating production operations, reducing labor intensity and improving flexibility.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0020] The following will clearly and completely describe the technical solutions in the embodiments of the present invention with reference to the accompanying drawings in the embodiments of the present invention. Obviously, the described embodiments are only some, not all, embodiments of the present invention.

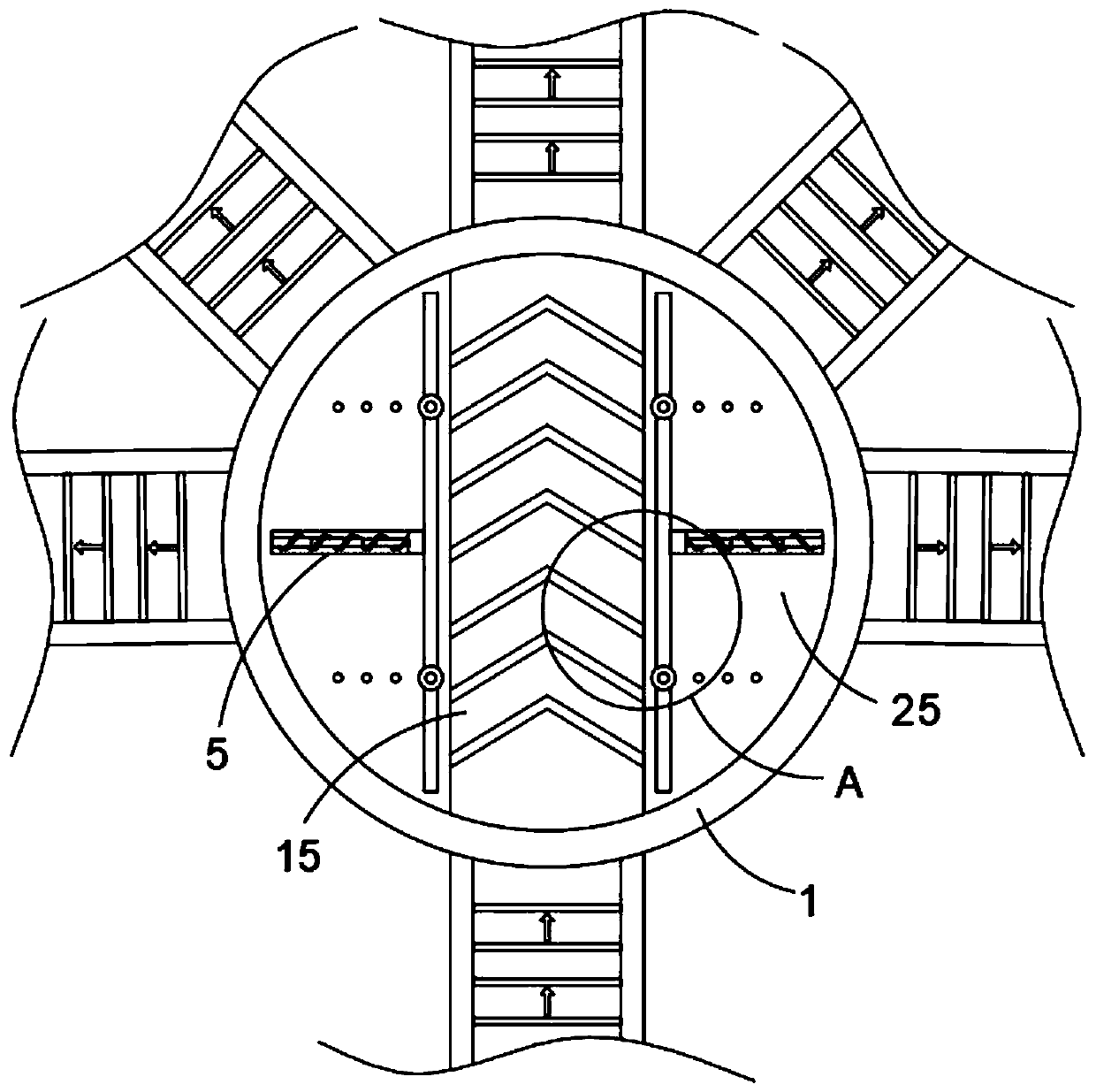

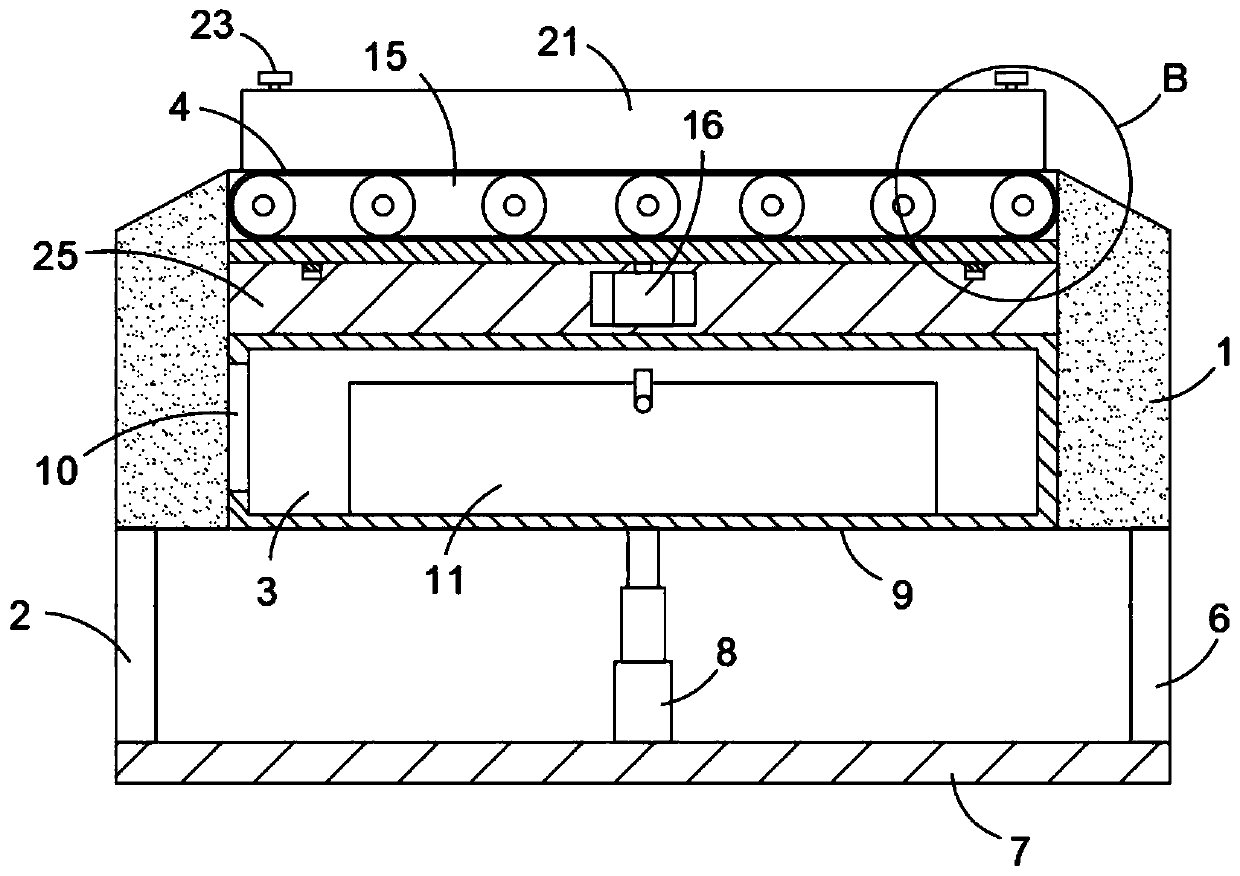

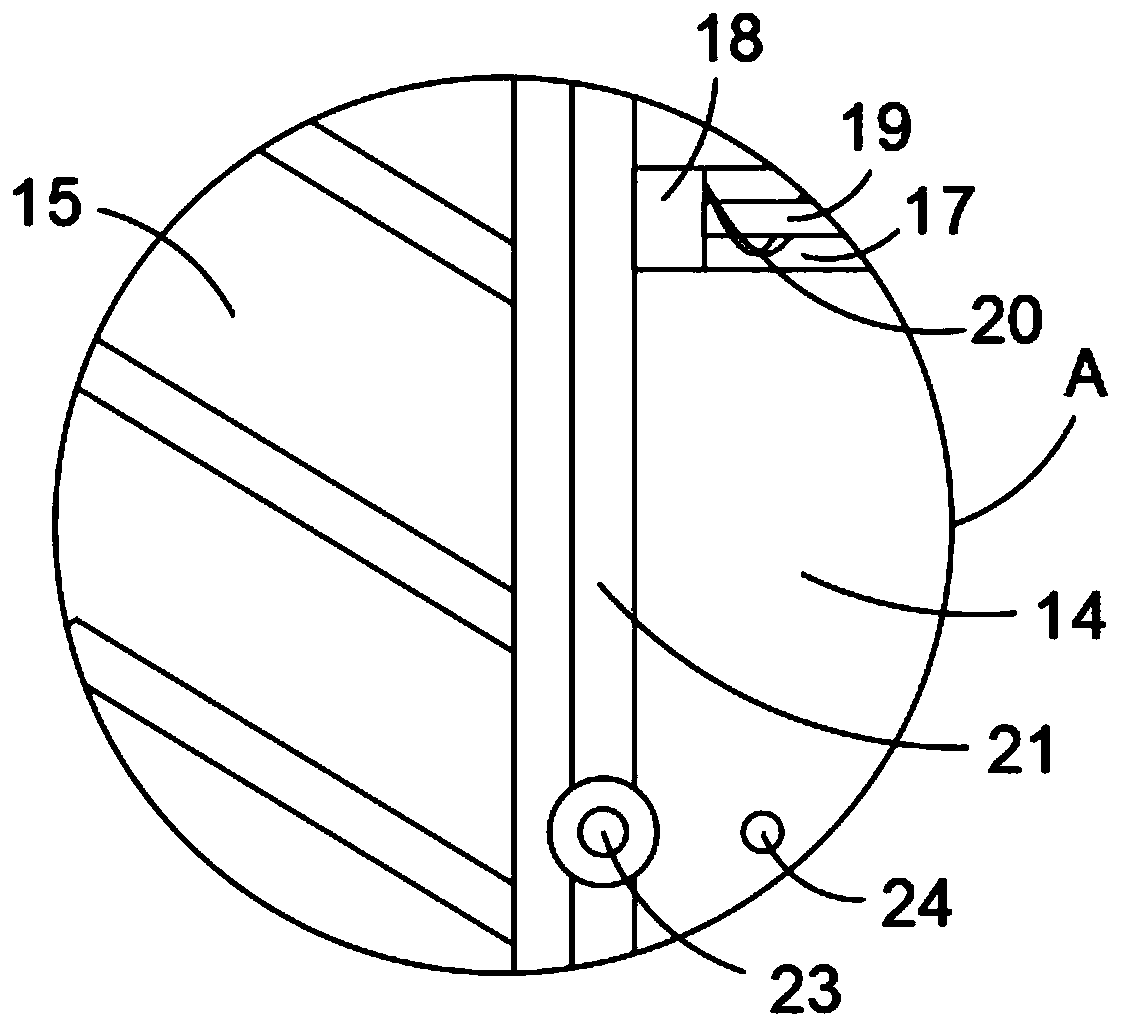

[0021] refer to Figure 1-4 , a kind of sorting machine for warehousing and logistics, including a body 1, the body 1 is a prototype columnar shape, the operator first places a main conveyor belt around the body, and then places a plurality of sorting conveyor belts around it, the main conveyor belt Various existing sensors are installed on the conveyor belt and the classification conveyor belt, which are used to classify and detect the goods on the main conveyor belt. When the goods are transported on the main conveyor belt, the goods are detected by the sensors on the conveyor belt. Carry out classification detection, this technology is equivalent to the existing g...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com