Sterile facial mask production process

A production process and mask technology, applied in the field of sterile mask production technology, can solve problems such as rupture, loss of effectiveness, deformation and expansion of mask cloth and mask bag, and achieve the effect of improving service life

Active Publication Date: 2019-07-26

绍兴美琪医疗科技有限公司

View PDF11 Cites 1 Cited by

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

[0003] At present, in the production of facial mask products, the traditional hot-pressing sterilization process is adopted. The disadvantage of this method is that some components in the facial mask liquid that are unstable under high temperature conditions will decompose and denature, lo

Method used

the structure of the environmentally friendly knitted fabric provided by the present invention; figure 2 Flow chart of the yarn wrapping machine for environmentally friendly knitted fabrics and storage devices; image 3 Is the parameter map of the yarn covering machine

View moreImage

Smart Image Click on the blue labels to locate them in the text.

Smart ImageViewing Examples

Examples

Experimental program

Comparison scheme

Effect test

Login to View More

Login to View More PUM

Login to View More

Login to View More Abstract

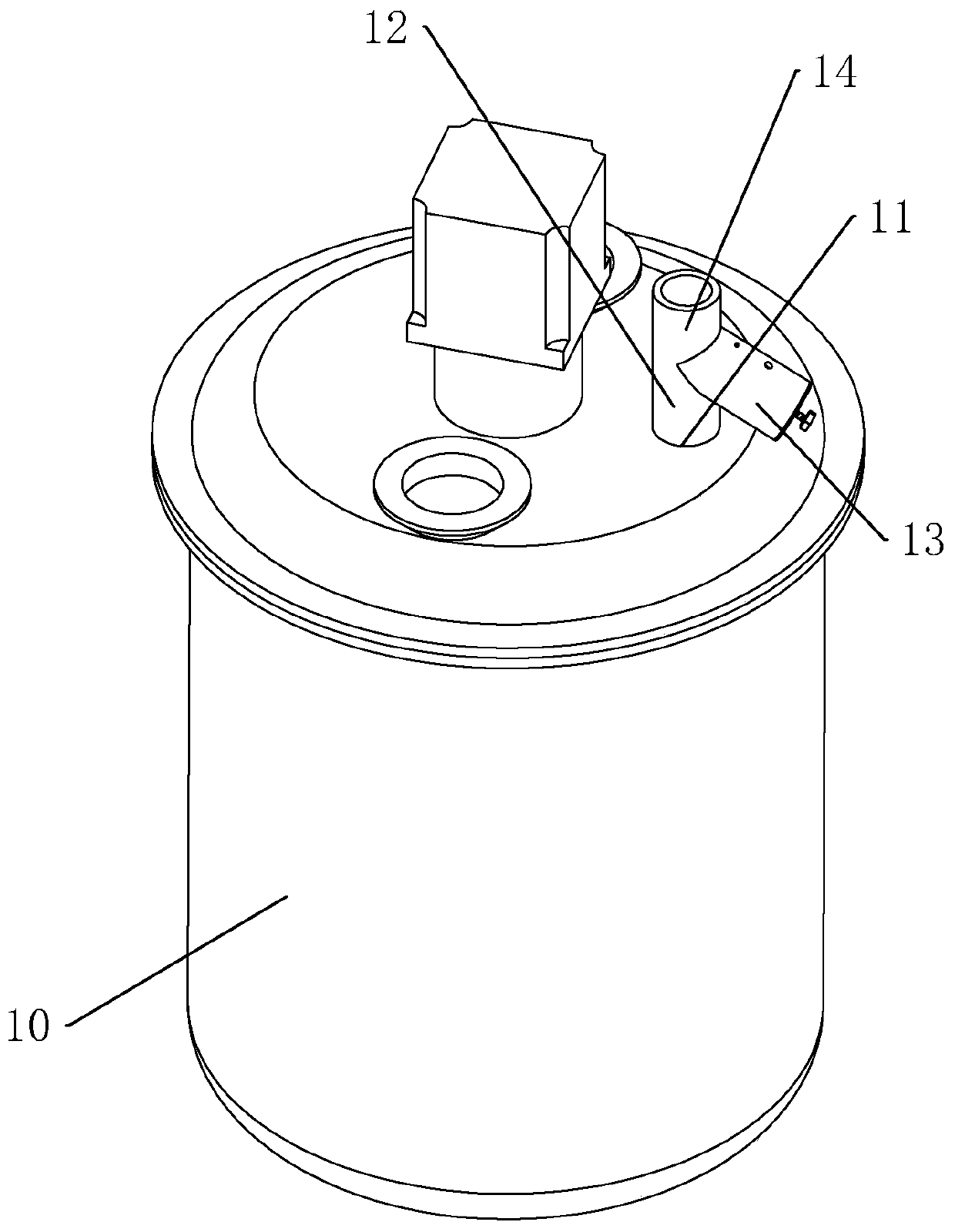

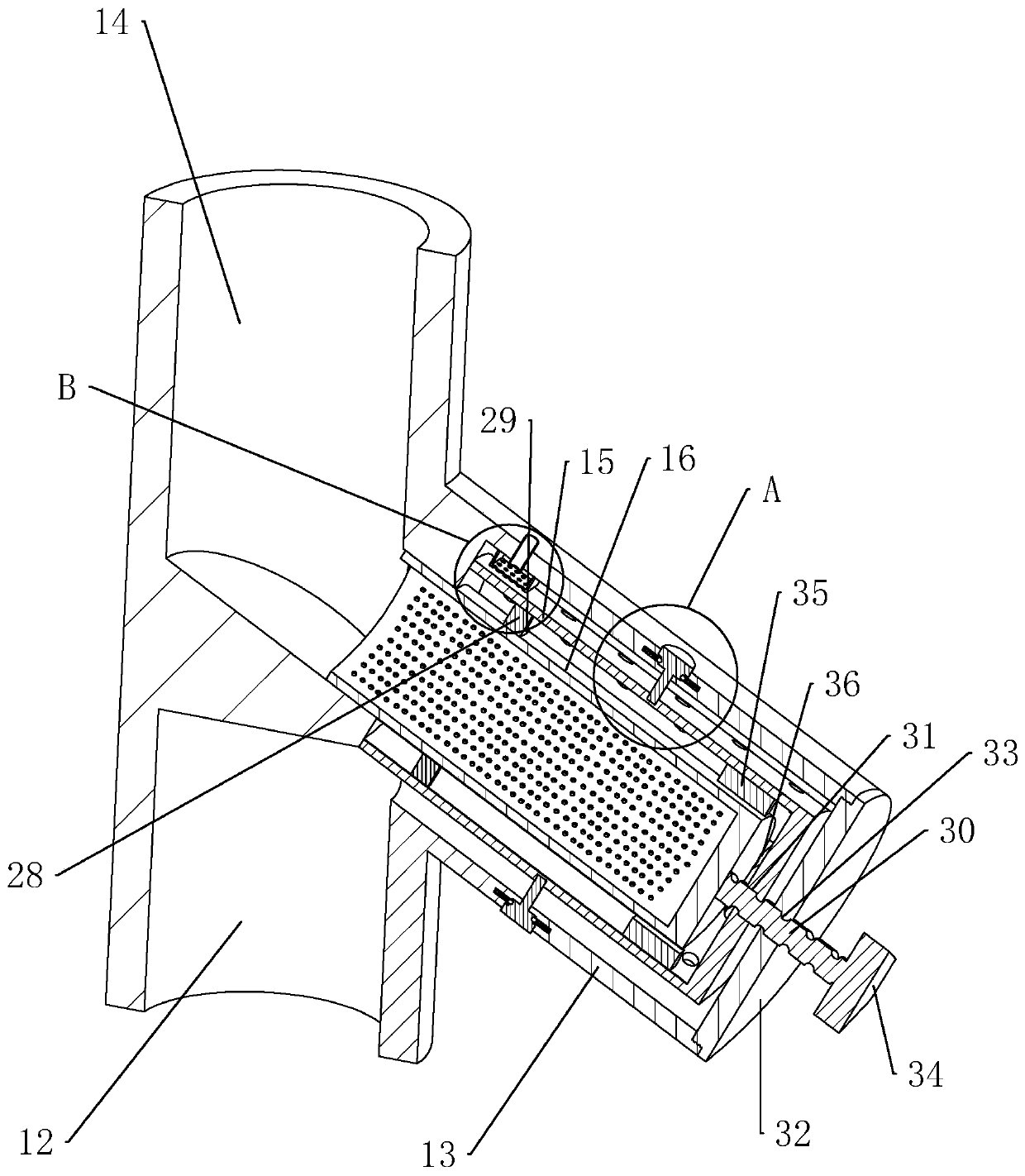

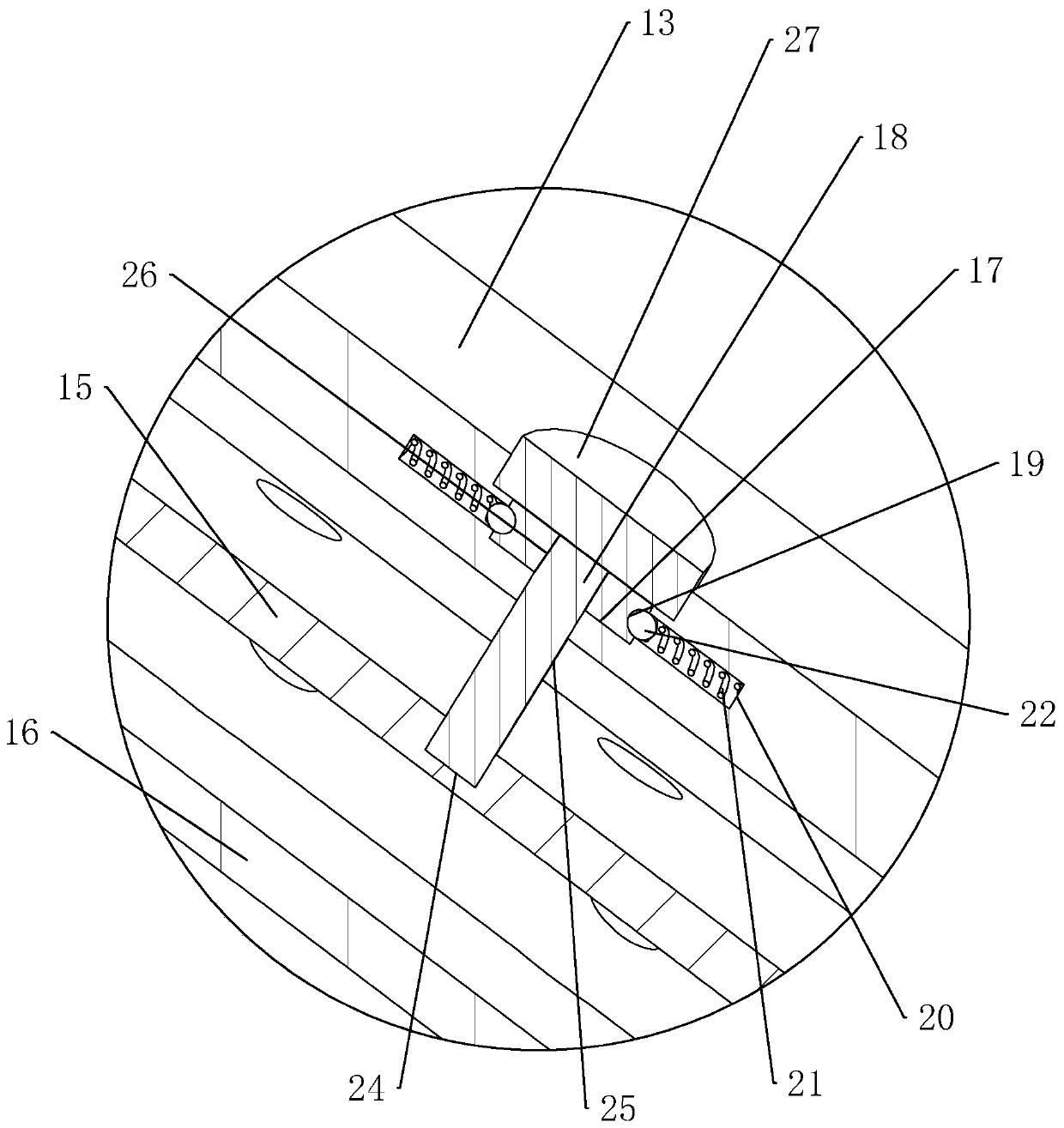

The invention discloses a sterile facial mask production process and relates to the technical field of mask production. The sterile facial mask production process comprises the steps: S1, preparing amaterial A and a material B, wherein the weight ratio of the material A to the material B is 1 to 1; S2, putting the material A into a reaction kettle, and raising the temperature to 115-120 DEG C, keeping the temperature for 20-30 minutes and executing cooling to room temperature; S3, introducing the material B into a reaction kettle through a stainless steel filter; S4, starting a reaction kettle to stir the materials A and B uniformly; S5, carrying out irradiation sterilization treatment on facial mask cloth by using electronic radiation, and filling the facial mask cloth into a sterile packaging bag; S6, filling the mixed solution mixed in S4 into a sterile packaging bag through a sterile pipeline, and sealing the packaging bag; S7, carrying out ozone sterilization treatment on the outer package of a sterile packaging bag. The sterile facial mask finished product is obtained through the seven steps. The sterile facial mask production process has the effect of protecting unstable components in the mask liquid from being decomposed while performing aseptic treatment on the mask.

Description

technical field [0001] The invention relates to the technical field of facial mask production, in particular to a production process for a sterile facial mask. Background technique [0002] In mask products, because the water content in the mask is very high, it is easily contaminated by microorganisms, so there are high requirements for sterilization and antiseptic capabilities. Existing facial masks usually use preservatives, which can protect facial mask products from microbial contamination and deterioration, so as to prolong the shelf life of the products. But it is a useless ingredient for skin care itself, and may even increase skin irritation and allergies. In order to ensure the safety of products and prevent consumers from possible infections caused by using products contaminated by microorganisms, if the amount of preservatives added is not enough, microorganisms may adapt to the surrounding growth environment and develop drug resistance, resulting in failure of ...

Claims

the structure of the environmentally friendly knitted fabric provided by the present invention; figure 2 Flow chart of the yarn wrapping machine for environmentally friendly knitted fabrics and storage devices; image 3 Is the parameter map of the yarn covering machine

Login to View More Application Information

Patent Timeline

Login to View More

Login to View More IPC IPC(8): A61K8/81A61K8/24A61K8/34A61K8/42A61K8/65A61K8/64A61K8/44A61K8/60A61K8/73A61Q19/00

CPCA61K8/73A61K8/345A61K8/44A61K8/24A61K8/42A61K8/735A61K8/65A61K8/64A61K8/60A61K8/8147A61Q19/00A61K2800/805

Inventor 戚平忠

Owner 绍兴美琪医疗科技有限公司

Who we serve

- R&D Engineer

- R&D Manager

- IP Professional

Why Patsnap Eureka

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com