A high-efficiency and energy-saving servo motor

A servo motor, high-efficiency and energy-saving technology, applied in electromechanical devices, electrical components, electrical components, etc., can solve problems such as power loss, hinder rotor rotation, affect mechanical energy utilization, etc., to improve efficiency, reduce friction coefficient, prevent temperature overly effective

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0021] The following will clearly and completely describe the technical solutions in the embodiments of the present invention with reference to the accompanying drawings in the embodiments of the present invention. Obviously, the described embodiments are only some, not all, embodiments of the present invention.

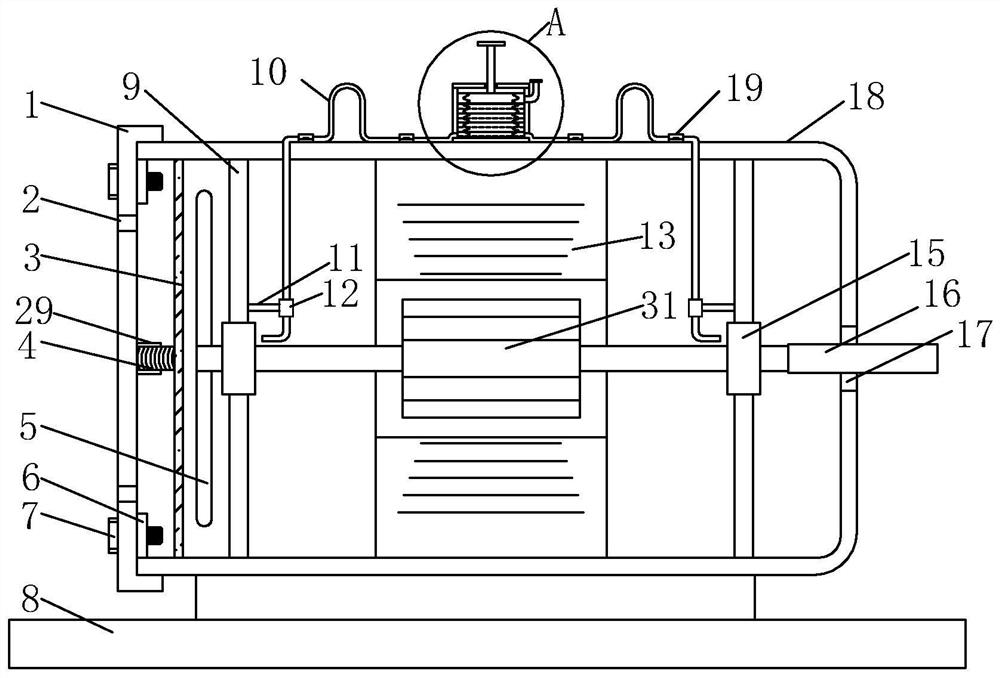

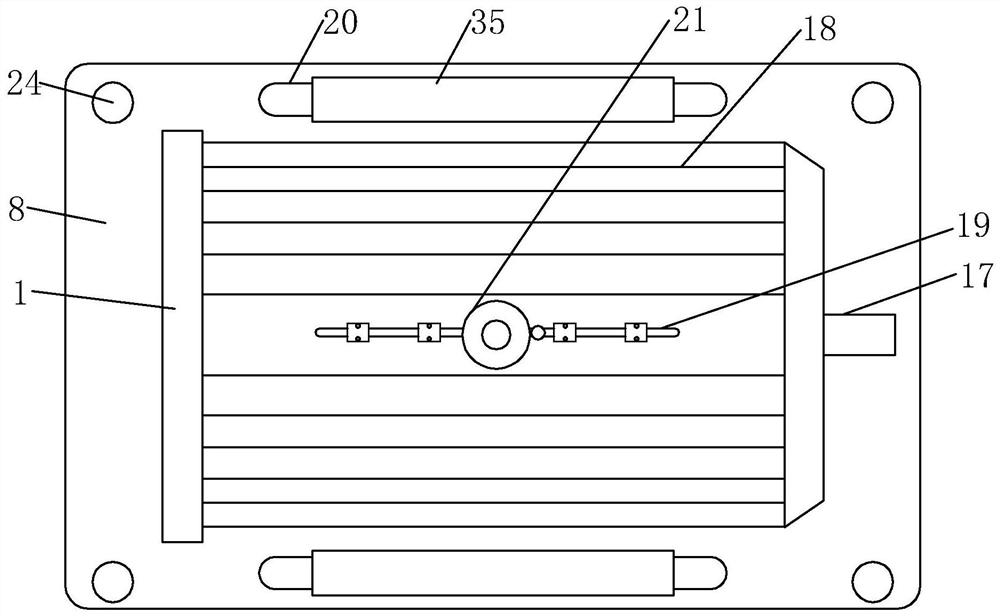

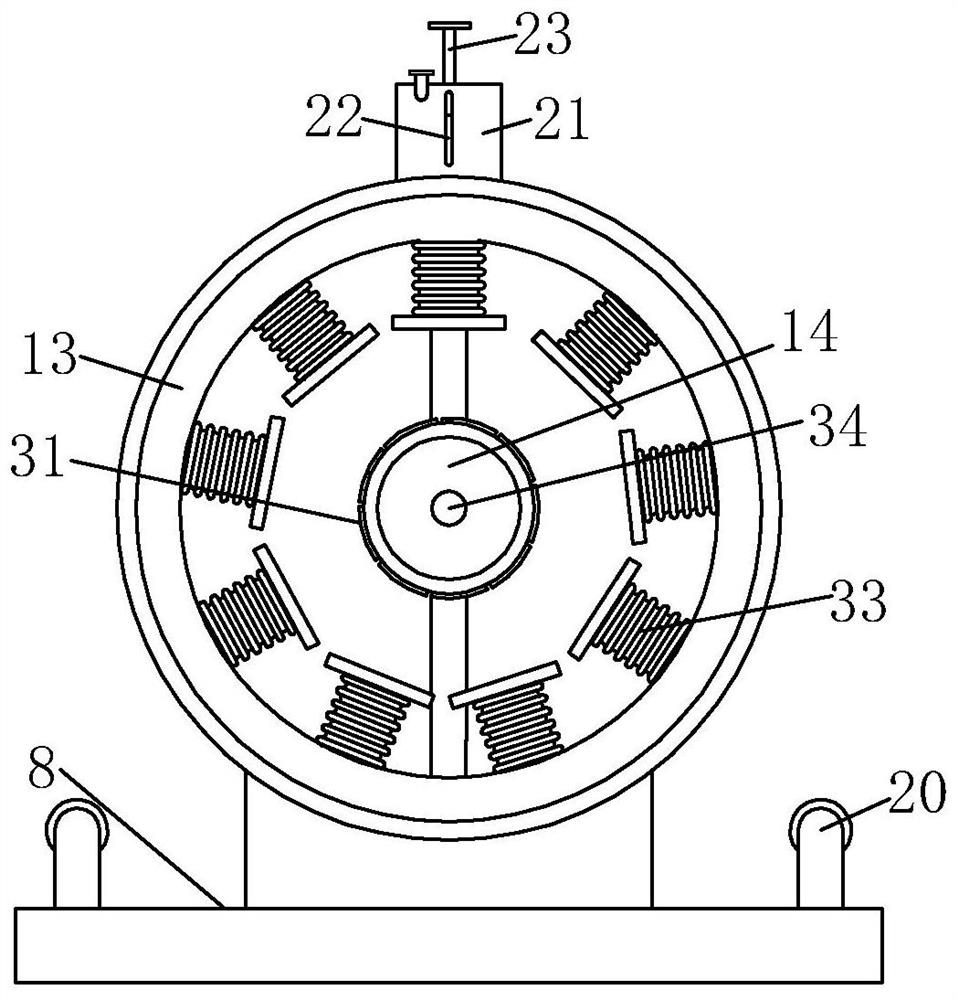

[0022] refer to Figure 1-5 , a high-efficiency energy-saving servo motor includes a base plate 8, handles 20 are fixedly connected to both sides of the base plate 8, handles 20 are provided with grip sleeves 35, and the grip sleeves 35 are made of rubber materials, and fixation holes 24 are provided around the base plate 8 , the design of the fixing hole 24 is convenient to fix the motor by fastening the bolts, the design of the handle 20 is convenient for holding the handle 20, and the motor is carried. Comfortable when moving, to prevent the motor from being too heavy during handling, which may cause scratches on the palm.

[0023] The upper end of the bottom pla...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com