A dual-purpose open and close low-velocity return wind tunnel

A low-speed, wind tunnel technology, applied in the field of wind tunnel experiments, can solve the problems of a large amount of time and manpower, long experiment preparation time, etc., and achieve the effect of reducing experiment preparation time, time and manpower expenditure

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0023] The present invention will be further described in detail below in conjunction with the accompanying drawings and specific embodiments.

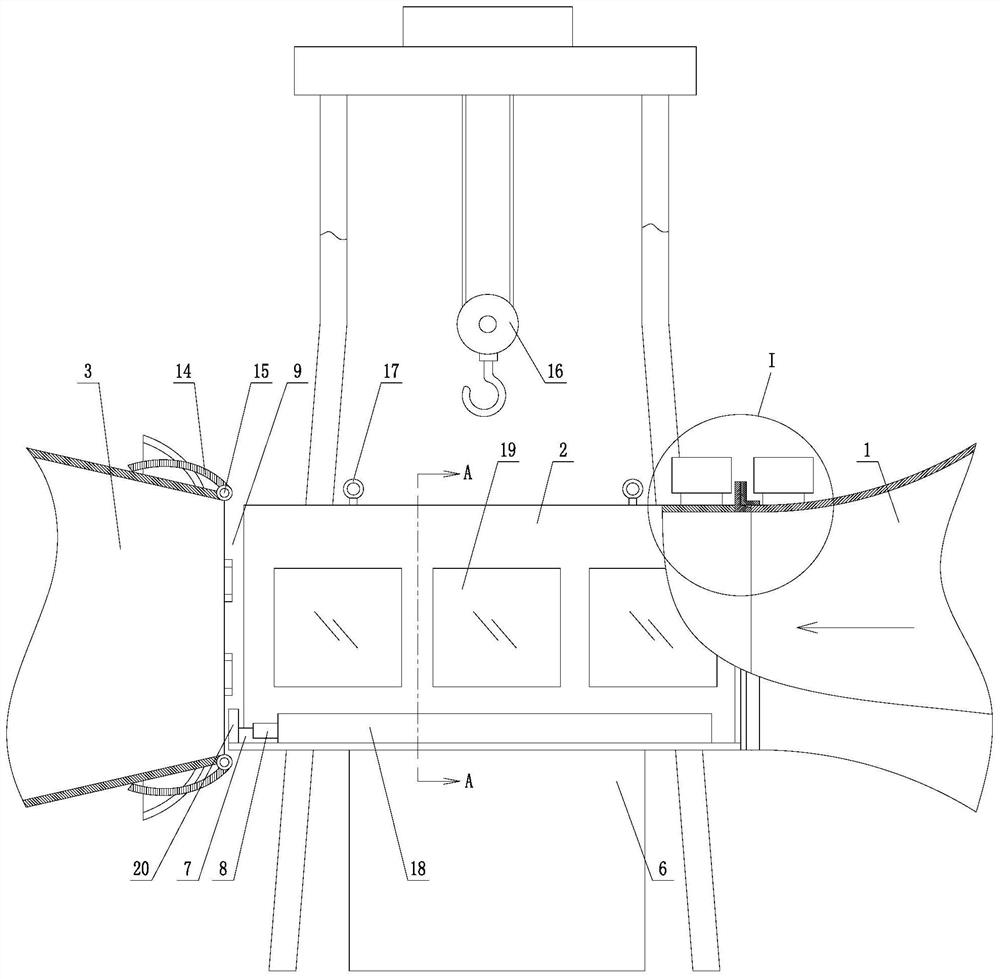

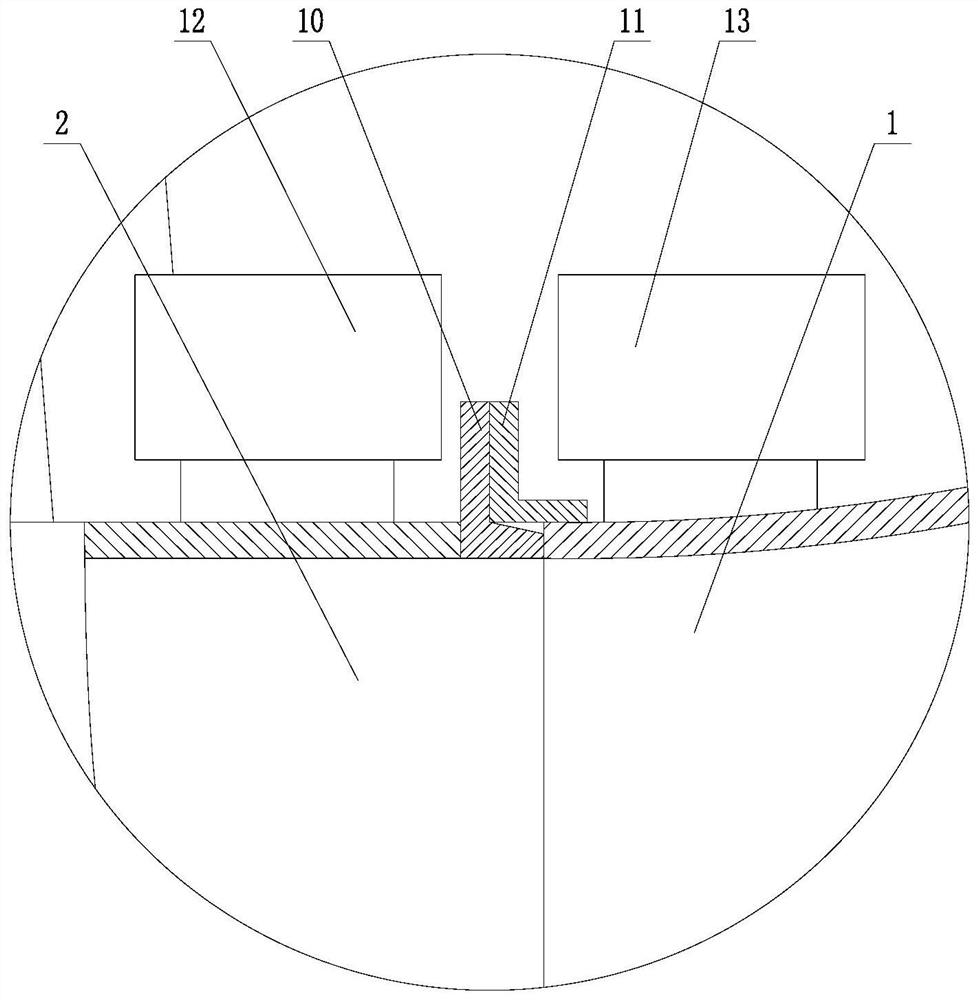

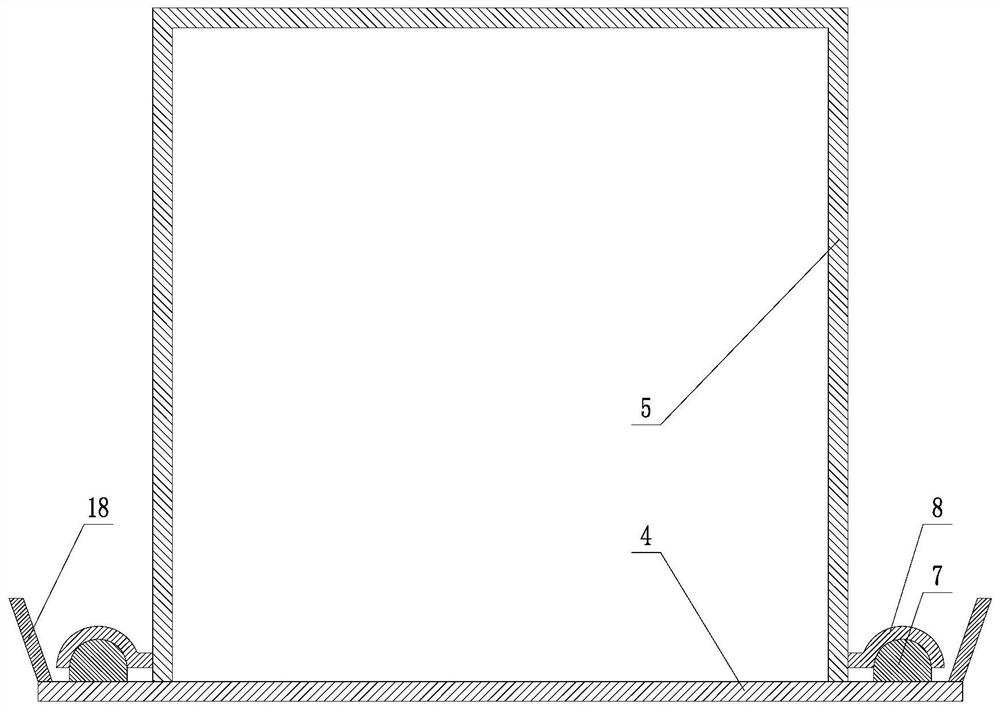

[0024] Such as Figure 1~4 As shown, a dual-purpose low-velocity return wind tunnel for opening and closing includes a contraction section 1, an experiment section 2, and a diffusion section 3. The contraction section 1, experiment section 2, and diffusion section 3 are distributed along a straight line, and the contraction section 1 and Diffusion section 3 is all fixed on the ground; Described experimental section 2 is divided into base plate 4 and upper cover 5, and base plate 4 is fixed on the ground by supporting base 6; Described upper cover 5 is fastened on the base plate 4, and upper cover 5 is connected When the bottom plate 4 is in the buckled state, it constitutes a complete experimental section 2; two parallel slide rails 7 are horizontally installed on the upper surface of the bottom plate 4, and slide plates 8 are respect...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com