Guide rod type acoustic grating pyrometer

A pyrometer and guide rod technology, used in thermometers, thermometers with physical/chemical changes, measuring devices, etc., can solve problems such as poor accuracy and low measurement upper limit, and achieve improved accuracy, high temperature resistance, and extended use. effect of life

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

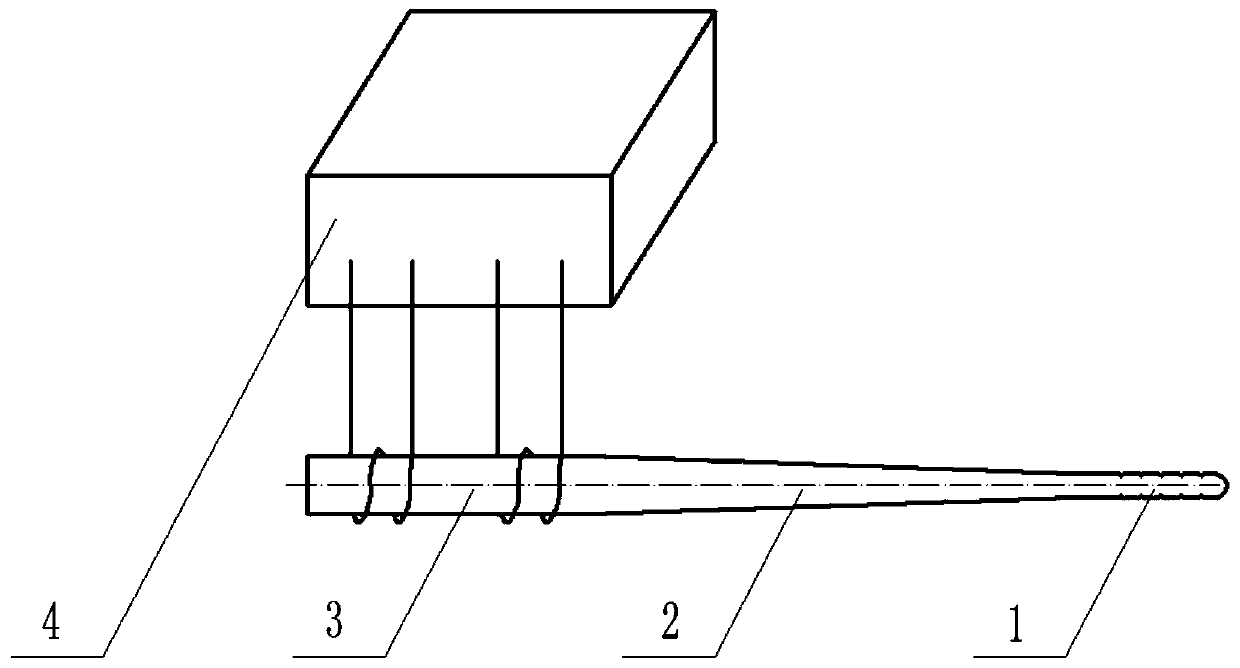

[0025] Such as figure 1 As shown, the guide rod type acoustic grid pyrometer disclosed in this embodiment includes a guide rod 1 , a sensor 3 , a buffer 2 and an electronic device 4 . Both the guide rod 1 and the buffer 2 and the buffer 2 and the sensor 3 are connected by welding, and the guide rod 1, the buffer 2 and the sensor 3 are guaranteed to be coaxial during welding.

[0026] This embodiment is suitable for the measured medium in an oxidizing environment. The guide rod 1 is made of precious metal iridium. In order to improve the comprehensive mechanical properties of the guide rod 1, the iridium guide rod 1 should be subjected to pressure processing such as forging or rolling.

[0027] The guide rod 1 is a cylinder with a diameter of Φ5mm and a length of 50mm. Five acoustic gratings are arranged along the axial direction of the guide rod 1, and the distance between two adjacent acoustic gratings is 5mm. The axial section of the acoustic grating is a chamfered isoscel...

Embodiment 2

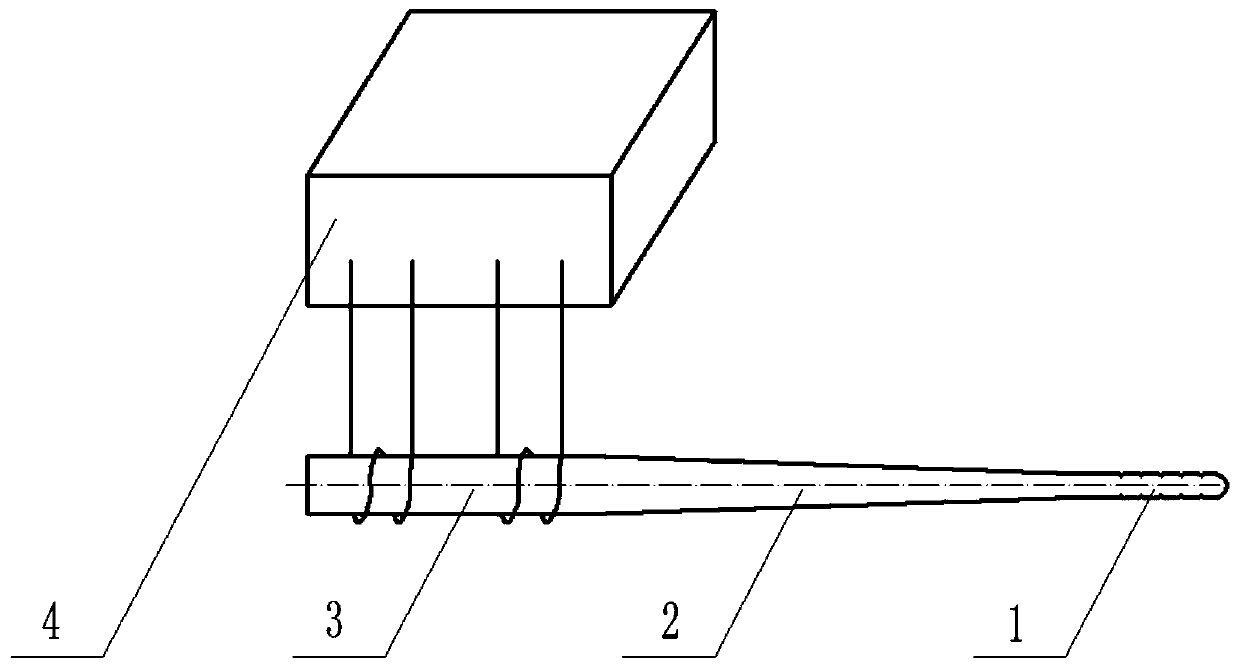

[0033] The guide rod 1 type acoustic grid pyrometer disclosed in this embodiment includes a guide rod 1 , a sensor 3 , a buffer 2 and an electronic device 4 . Both the guide rod 1 and the buffer 2 and the buffer 2 and the sensor 3 are connected by welding, and the guide rod 1, the buffer 2 and the sensor 3 are guaranteed to be coaxial during welding.

[0034] This embodiment is suitable for the measured medium in a reducing or neutral environment, and the guide rod 1 is made of tungsten, a refractory metal material.

[0035] The material of the buffer 2 is molybdenum, and it is welded with the guide rod 1 by vacuum electron beam. The cone angle of the buffer 2 is 22°.

[0036] The guide rod 1 is a cylinder with a diameter of Φ5mm and a length of 50mm. Five acoustic gratings are arranged along the axial direction of the guide rod 1, and the distance between two adjacent acoustic gratings is 5mm. The axial section of the acoustic grating is a chamfered isosceles triangle, the ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| melting point | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com