Heat source tower control method and control device and heat source tower

A control method and technology of a control device, which are applied in heating and ventilation control systems, heating and ventilation safety systems, mechanical equipment, etc., can solve problems such as inaccurate judgment of the degree of frost formation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0063] The following description and the accompanying drawings sufficiently illustrate specific embodiments herein to enable those skilled in the art to practice them. Portions and features of some embodiments may be included in or substituted for those of other embodiments. The scope of the embodiments herein includes the full scope of the claims, and all available equivalents of the claims.

[0064] One of the objectives of the present invention is to provide a control method for a heat source tower, which is used in a heat source tower, and the heat source tower is provided with a heat exchange device for the heat source tower.

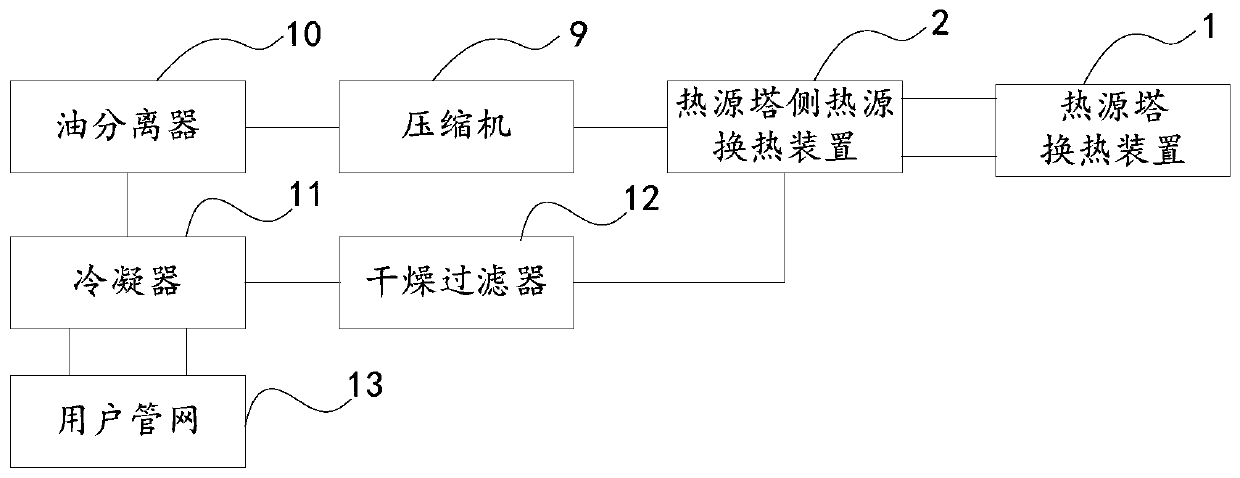

[0065] Such as figure 1 As shown, the heat source tower control method includes:

[0066] Step S1: According to the real-time temperature of the external environment, determine the set value of the wind pressure of the heat exchange device of the heat source tower, or the set value of the suction temperature of the compressor in the heat pump uni...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com