Double-suction sewage pump

A technology for sewage pumps and double-suction pumps, applied to pumps, pump components, non-variable pumps, etc., can solve problems such as excessive axial force of single-suction pumps, achieve excessive axial force and improve pump efficiency , The effect of reducing the specific speed

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0013] The present invention will be further described below in conjunction with drawings and embodiments.

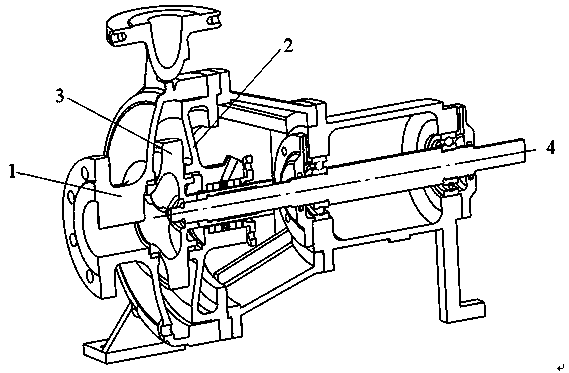

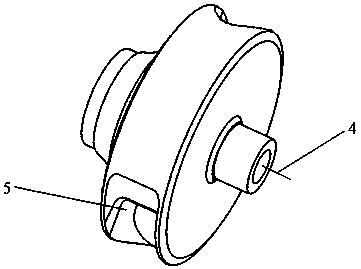

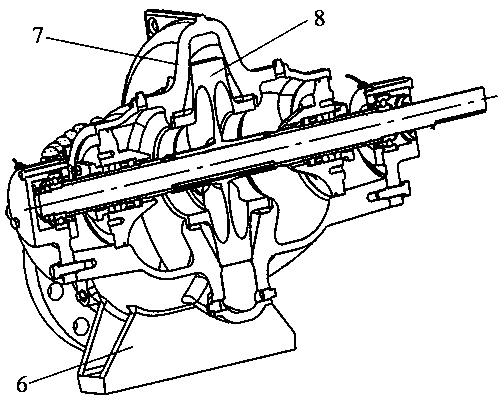

[0014] The double-suction sewage pump consists of a double-suction pump body 6, a double-suction pump cover 7 and a double-suction sewage pump impeller 8. The water inlet and outlet of the pump connected to the water inlet and outlet pipes are all on the pump body. The double-suction pump body 6 It is connected with the pump cover 7 of the double-suction pump through the center opening. There are two flow channels 5 on both sides of the impeller of the sewage pump, and the two flow channels are symmetrical about the center of the axis line 4, that is, one flow channel rotates 180° around the axis line as the center of the other flow channel As a result, the flow passages on both sides are symmetrically distributed back to back, and outside a certain outer diameter of the impeller, the flow passages on both sides merge.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com