Aluminum alloy template system receiving template embedded device

A technology of aluminum alloy formwork and pre-embedded device, which is applied to the connection parts of formwork/formwork/work frame, the on-site preparation of building components, construction, etc. installation, concrete leakage and other problems, to achieve the effect of light weight, simple structure and reduced loss cost

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0015] The present invention will be further described below in conjunction with accompanying drawing:

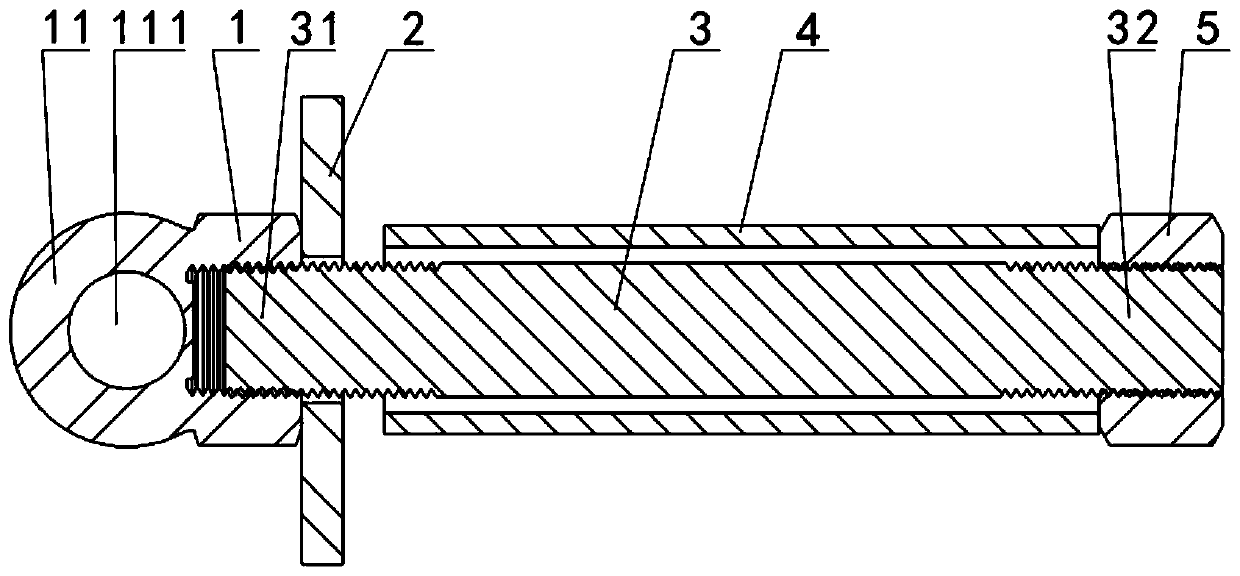

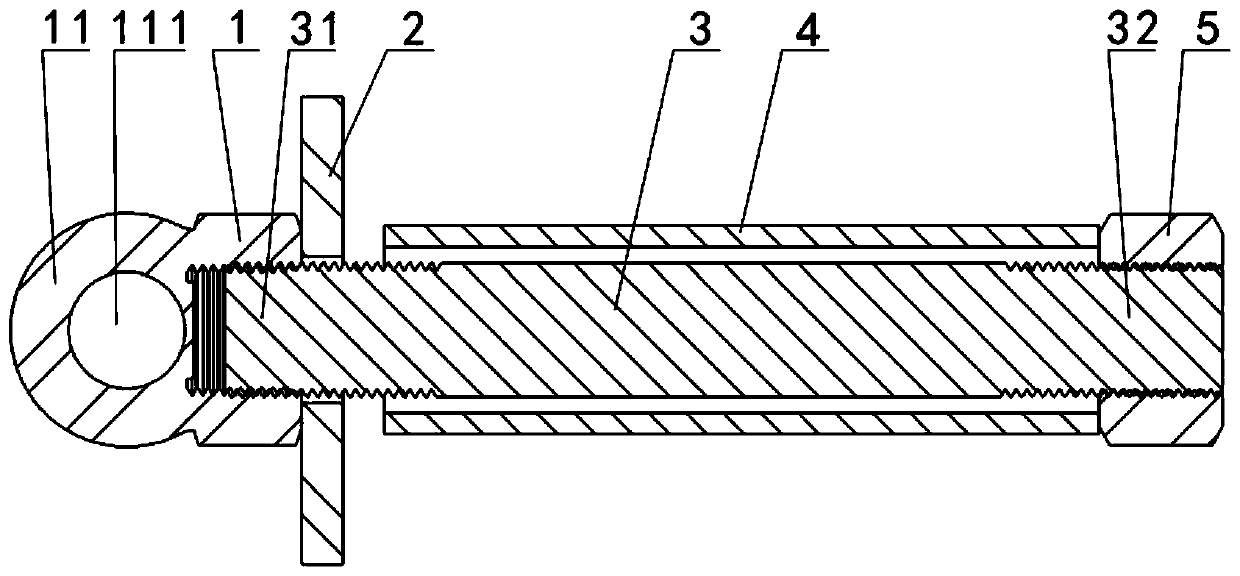

[0016] Such as figure 1 As shown, the aluminum alloy formwork system of the present invention undertakes the pre-embedding device of the formwork including a threaded rod 3, a nut 1, a gasket 2, a nut 5 and a sleeve 4, and the two ends of the threaded rod 3 are respectively provided with a first threaded segment 31 The thread direction of the first threaded segment 31 and the second threaded segment 32 is opposite to that of the second threaded segment 32, the gasket 2 and the nut 1 are fitted outside the first threaded segment 31 from the inside to the outside, and the nut 5 is fitted to the second threaded segment Outside the section 32, the sleeve 4 is set outside the middle section of the threaded rod 3 and is located between the gasket 2 and the nut 5. The outer end of the nut 1 is provided with an outer convex portion 11, and the outer convex portion 11 is provided wi...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com