Cloth weaving process and special air jet loom

An air-jet loom and process technology, applied in looms, textiles, textiles and papermaking, etc., can solve problems such as reducing the production efficiency of cloth, and achieve the effect of reducing the possibility of separation and improving production efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0034] Embodiment one: a weaving process, comprising the following steps:

[0035] a. Warp delivery: send the warp to the host system through the let-off mechanism;

[0036] b. Weft yarn supply: provide weft yarn through the weft yarn supply mechanism;

[0037] c. Weft insertion: introduce the weft thread into the host system through the weft insertion mechanism;

[0038] d. Forming the shed: the warp yarn is driven by the opening mechanism to divide the warp yarn into upper and lower layers, forming a shed passage for the weft carrier to pass through;

[0039] e. Weft yarn: the weft yarn is beaten to the weaving mouth through the beating mechanism to form a fabric;

[0040] f. Cloth collection: Put the reel into the take-up roller 34, and then collect the cloth through the reel; when the reel needs to be replaced, quickly replace the reel through the roll changing device 3.

Embodiment 2

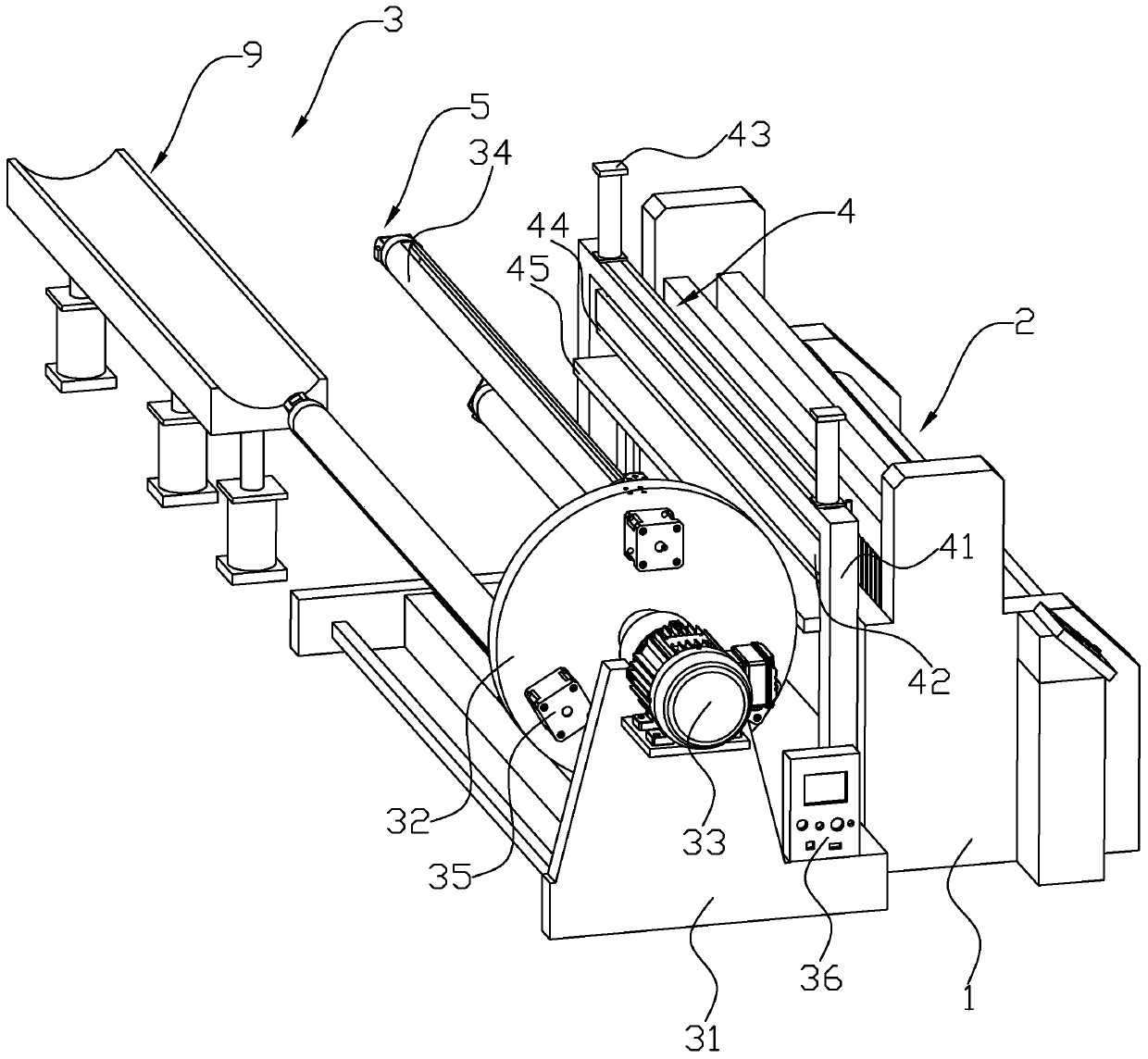

[0041] Embodiment two: a kind of air-jet loom, as figure 1 As shown, it includes a frame 1 and a weaving device 2; the weaving device 2 includes a weft yarn supply mechanism, a weft insertion mechanism, a weft beating mechanism, a shedding mechanism and a warp let-off mechanism.

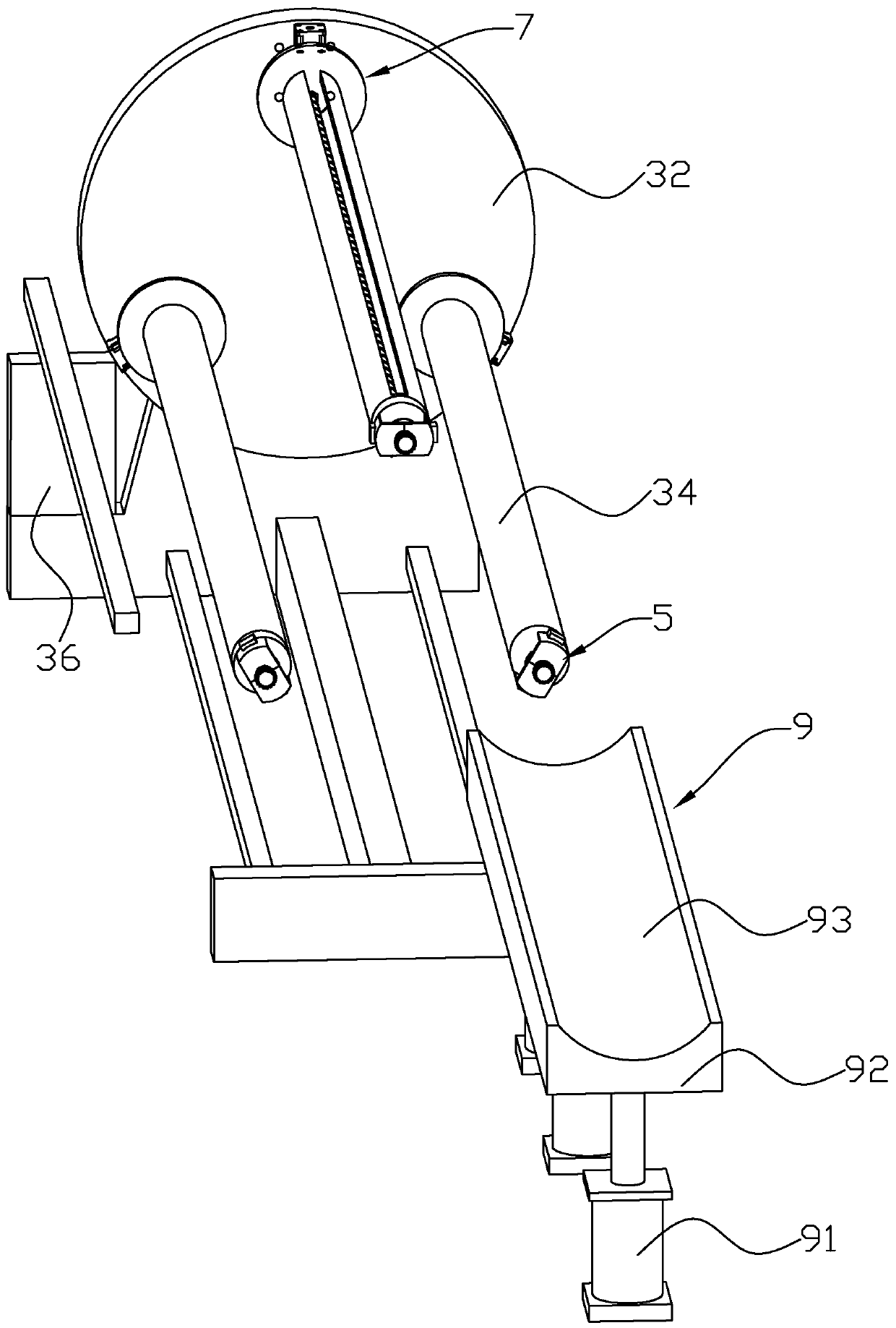

[0042] Such as figure 1 As shown, the roll changing device 3 is installed on the frame 1, and the roll changing device 3 includes a roll changing frame 31 fixedly connected to the discharge end of the frame 1, a turntable 32 connected to the roll changing frame 31 through bearing rotation, and a roll changing frame 32 installed on the roll changing Frame 31 is used to drive the first drive motor 33 that turntable 32 rotates and horizontal rotation is connected to turntable 32 a plurality of take-up rollers 34 on one side away from first drive motor 33; An eager assembly 4 is arranged on the top; a limit mechanism 5 for limiting the reel is installed at one end of each take-up roller 34 away from the...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com