Spandex blended fiber

A technology of blending fibers and spandex fibers, applied in the field of spinning yarns, can solve the problems of undyed performance improvement, fiber improvement, etc., and achieve the effect of enhancing dyeing performance and bacteriostatic activity, and not easy to gel agglomeration

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

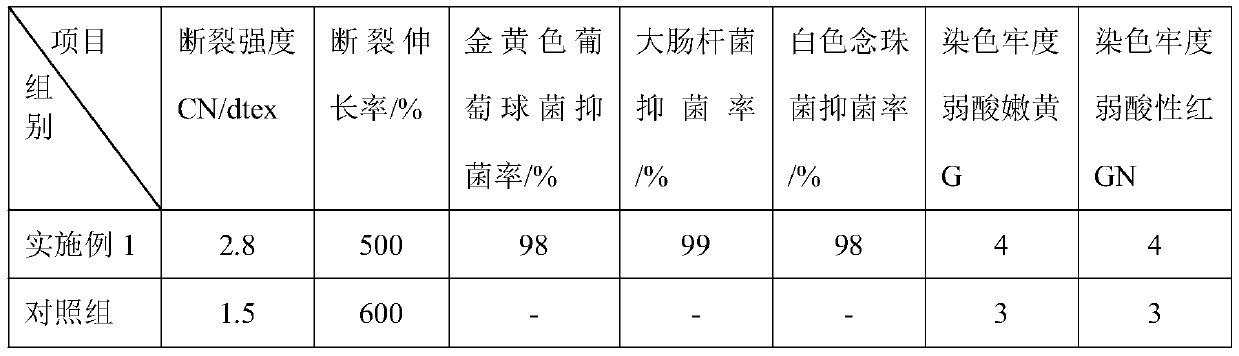

Embodiment 1

[0033] A spandex blended fiber is formed by blending 85% of 20S cotton fiber and 15% of 40D modified spandex fiber by mass percentage of fiber raw materials;

[0034] Wherein, modified spandex fiber is made up of each component of following parts by weight:

[0035] 10 parts of 4,4'-diphenylmethane diisocyanate;

[0036] 43 parts of polytetrahydrofuran ether glycols;

[0037] Chain extender: 1 part of ethylenediamine;

[0038] Stabilizer: 0.1 part of LRD-3;

[0039] Terminator: 2 parts of diethylamine;

[0040] 0.2 parts of quaternary ammonium salt cetyltrimethylammonium chloride;

[0041] Modification additive: 2 parts of 4,4'-dicyclohexylmethane diisocyanate and 1 part of biomass graphene.

Embodiment 2

[0043] The difference between Example 2 and Example 1 is that the ratio of raw materials is different: 11 parts of 4,4'-diphenylmethane diisocyanate; 45 parts of polytetrahydrofuran ether glycol; chain extender: 1 part of ethylenediamine; stable Agent: LRD-30.1 parts; Terminator: 2 parts of diethylamine; 0.2 parts of quaternary ammonium salt cetyltrimethylammonium chloride; modification additive: 3 parts of 4,4′-dicyclohexylmethane diisocyanate Substance Graphene 1 part.

Embodiment 3

[0045] The difference between Example 3 and Example 1 is that the ratio of raw materials is different: 12 parts of 4,4'-diphenylmethane diisocyanate; 45 parts of polytetrahydrofuran ether glycol; chain extender: 1 part of ethylenediamine; stable Agent: LRD-30.1 parts; Terminator: 2 parts of diethylamine; 0.2 parts of quaternary ammonium salt cetyltrimethylammonium chloride; modification additive: 3 parts of 4,4′-dicyclohexylmethane diisocyanate Substance graphene 1.5 parts.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com