Alpha-olefin polymerization catalyst, preparation method thereof and alpha-olefin polymerization method

A technology of olefin polymerization and catalyst, applied in the field of α-olefin polymerization catalyst and its preparation, and α-olefin polymerization, can solve the problems of high polymerization activity, lower product viscosity and performance, and lower polymerization activity, and achieve simple preparation method, The effect of high catalytic activity and low cost

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

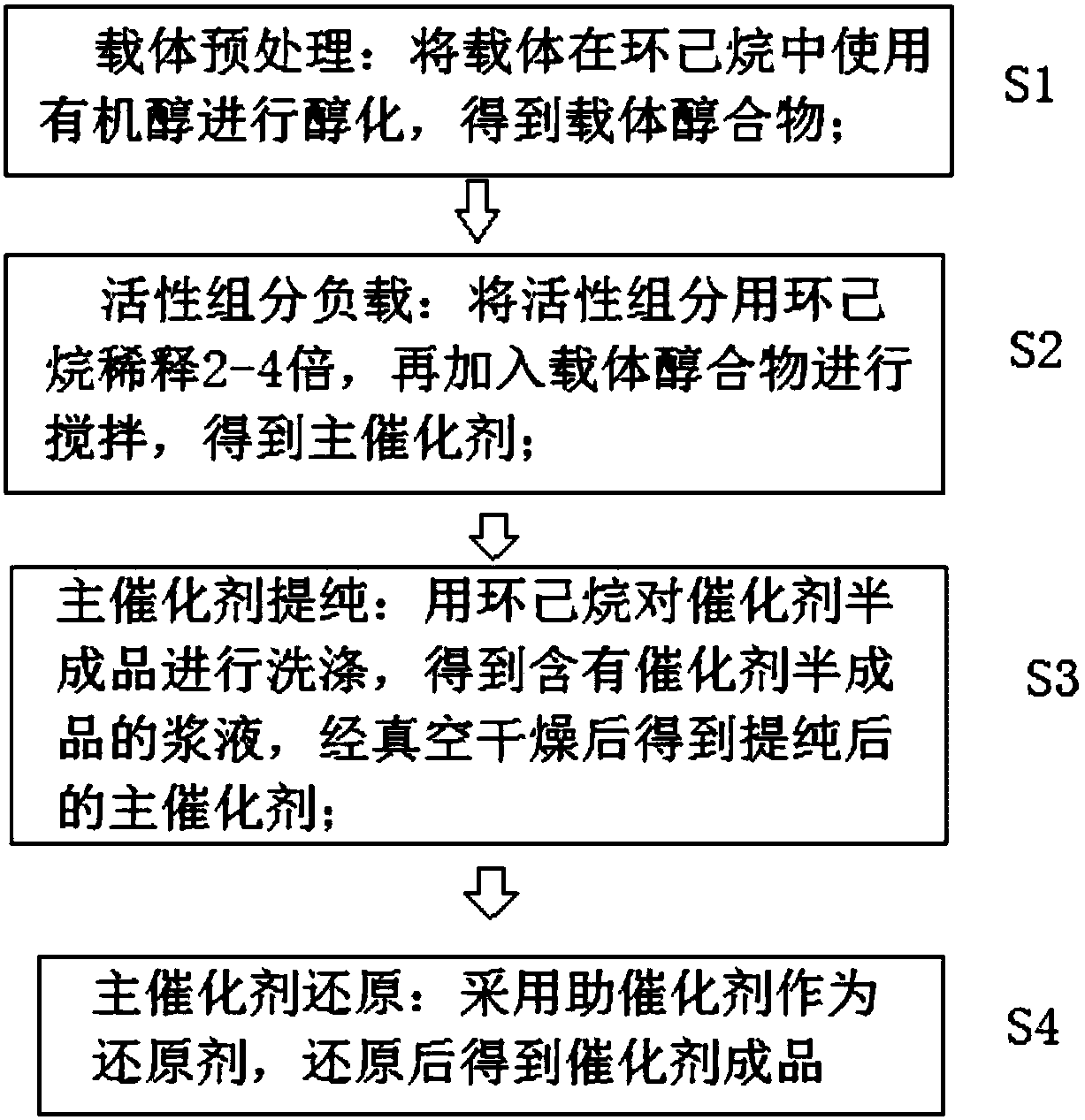

Method used

Image

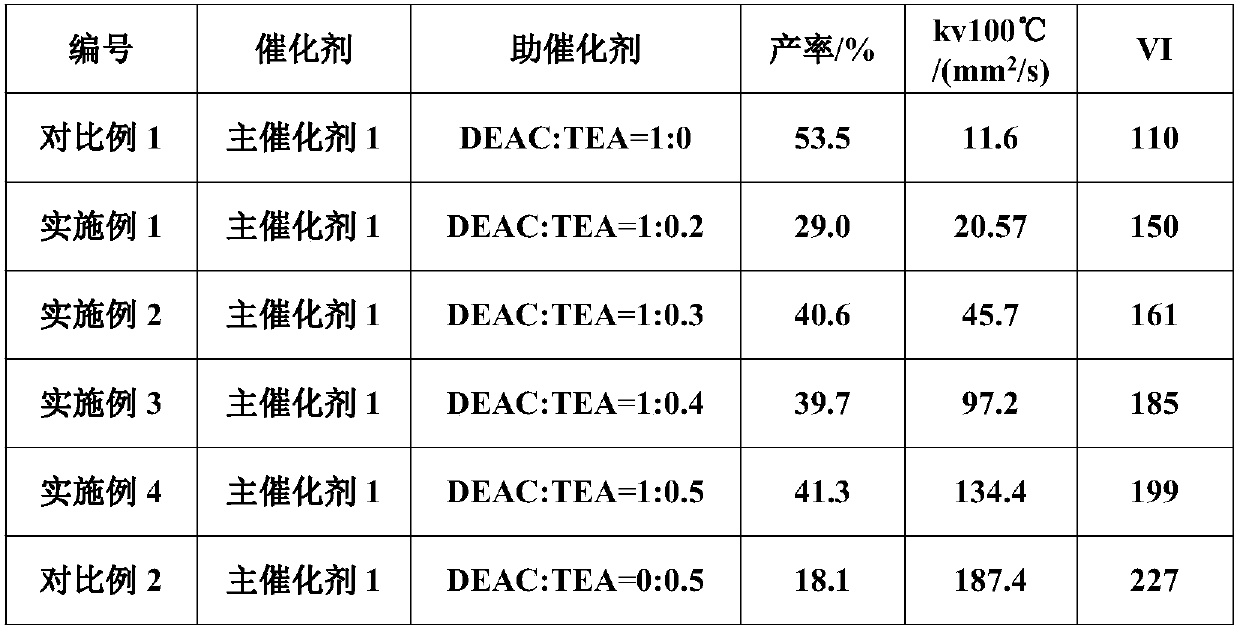

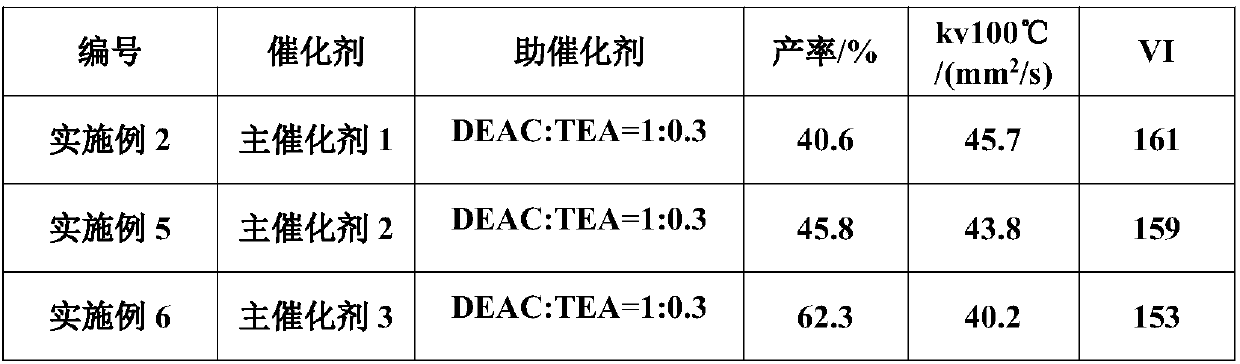

Examples

preparation example 1

[0062] Preparation of main catalyst 1

[0063] A three-necked reaction flask equipped with a stirrer and a thermometer was replaced with high-purity nitrogen for 3 times, and 15.5g of MgCl was added to the reaction vessel. 2 and 50ml of cyclohexane; at 60°C, add 10ml of n-butanol dropwise at a speed of 3 to 4 seconds / drop to form an alcoholate with the carrier;

[0064] After the reaction is completed, reduce the temperature to 25 ° C, take 2.55 ml of titanium tetrachloride, add cyclohexane with twice the volume ratio to make a titanium tetrachloride solution, and add it to the carrier at a rate of 3 to 4 seconds / drop under stirring. In the alcohol compound, continue stirring for 1h after the dropwise addition;

[0065] After the reaction of the supported titanium active center is completed, under the protection of an inert gas, the reaction solution is filtered out, the above-mentioned generated materials are subjected to multiple thermal washings with cyclohexane, and the w...

preparation example 2

[0067] Preparation of main catalyst 2

[0068] A three-necked reaction flask equipped with a stirrer and a thermometer was replaced with high-purity nitrogen for 3 times, and 15.5g of MgCl was added to the reaction vessel. 2 and 50ml of cyclohexane; at 60°C, add 10ml of n-butanol dropwise at a speed of 3 to 4 seconds / drop to form an alcoholate with the carrier;

[0069] After the reaction, reduce the temperature to 25°C, take 3.83 ml of titanium tetrachloride, add cyclohexane with twice the volume ratio to make a titanium tetrachloride solution, and add it to the carrier at a rate of 3 to 4 seconds / drop under stirring. In the alcohol compound, continue stirring for 1h after the dropwise addition;

[0070] After the reaction of the supported titanium active center is completed, under the protection of an inert gas, the reaction solution is filtered out, the above-mentioned generated materials are subjected to multiple thermal washings with cyclohexane, and the washed supernata...

preparation example 3

[0072] Preparation of main catalyst 3

[0073] A three-necked reaction flask equipped with a stirrer and a thermometer was replaced with high-purity nitrogen for 3 times, and 15.5g of MgCl was added to the reaction vessel. 2 and 50ml of cyclohexane; at 60°C, add 10ml of n-butanol dropwise at a speed of 3 to 4 seconds / drop to form an alcoholate with the carrier;

[0074] After the reaction, lower the temperature to 25°C, take 5.1 ml of titanium tetrachloride, add twice the volume ratio of cyclohexane to make a titanium tetrachloride solution, and add it to the carrier at a rate of 3 to 4 seconds / drop under stirring In the alcohol compound, continue stirring for 1h after the dropwise addition;

[0075] After the reaction of the supported titanium active center is completed, under the protection of an inert gas, the reaction solution is filtered out, the above-mentioned generated materials are subjected to multiple thermal washings with cyclohexane, and the washed supernatant li...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com