Paper core technology and paper core thereof

A paper core and process technology, applied in the field of paper cores, can solve the problems of reducing yield, wrinkling of winding materials, inability to effectively guarantee straightness and stiffness, etc., and achieve the effect of enhancing bonding strength and increasing linearity accuracy.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

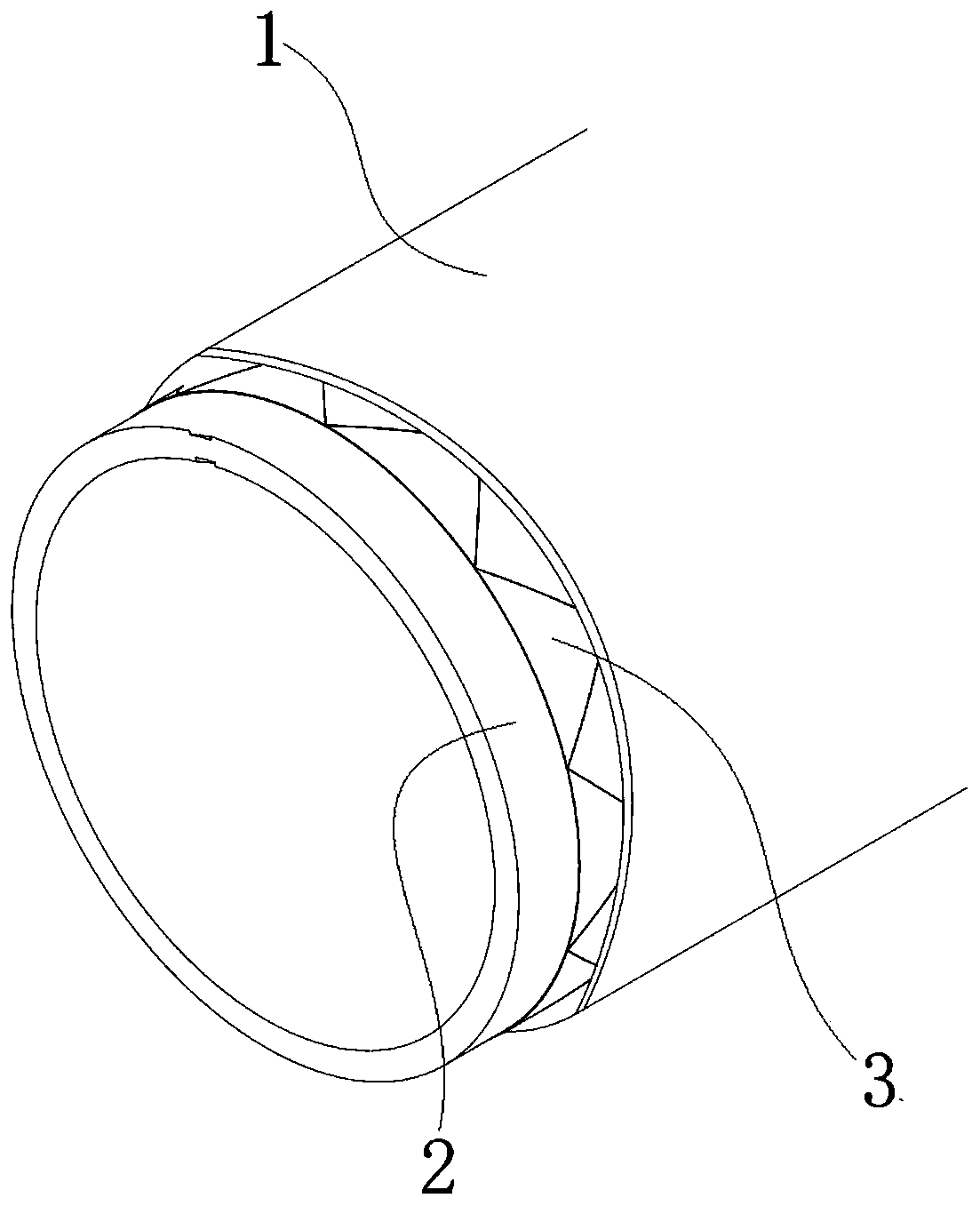

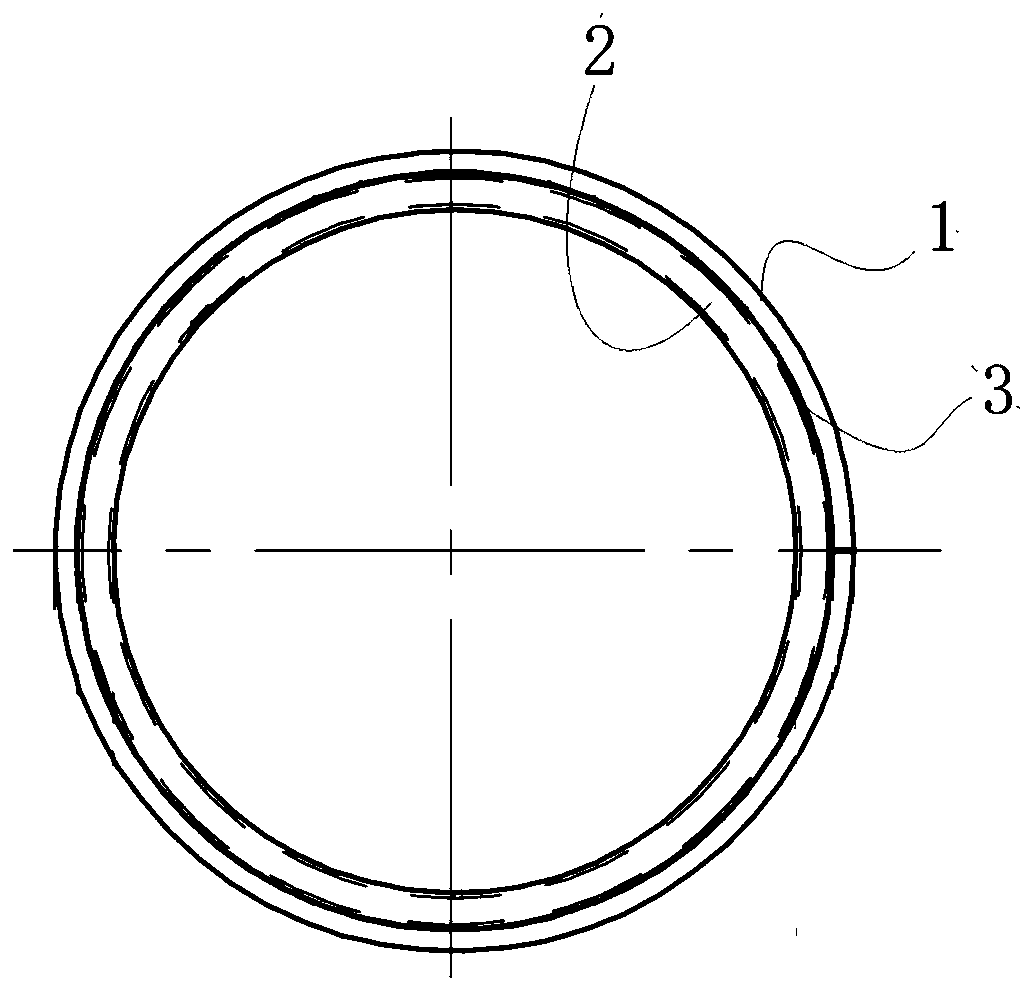

[0020] The present invention will be further described below in conjunction with the accompanying drawings.

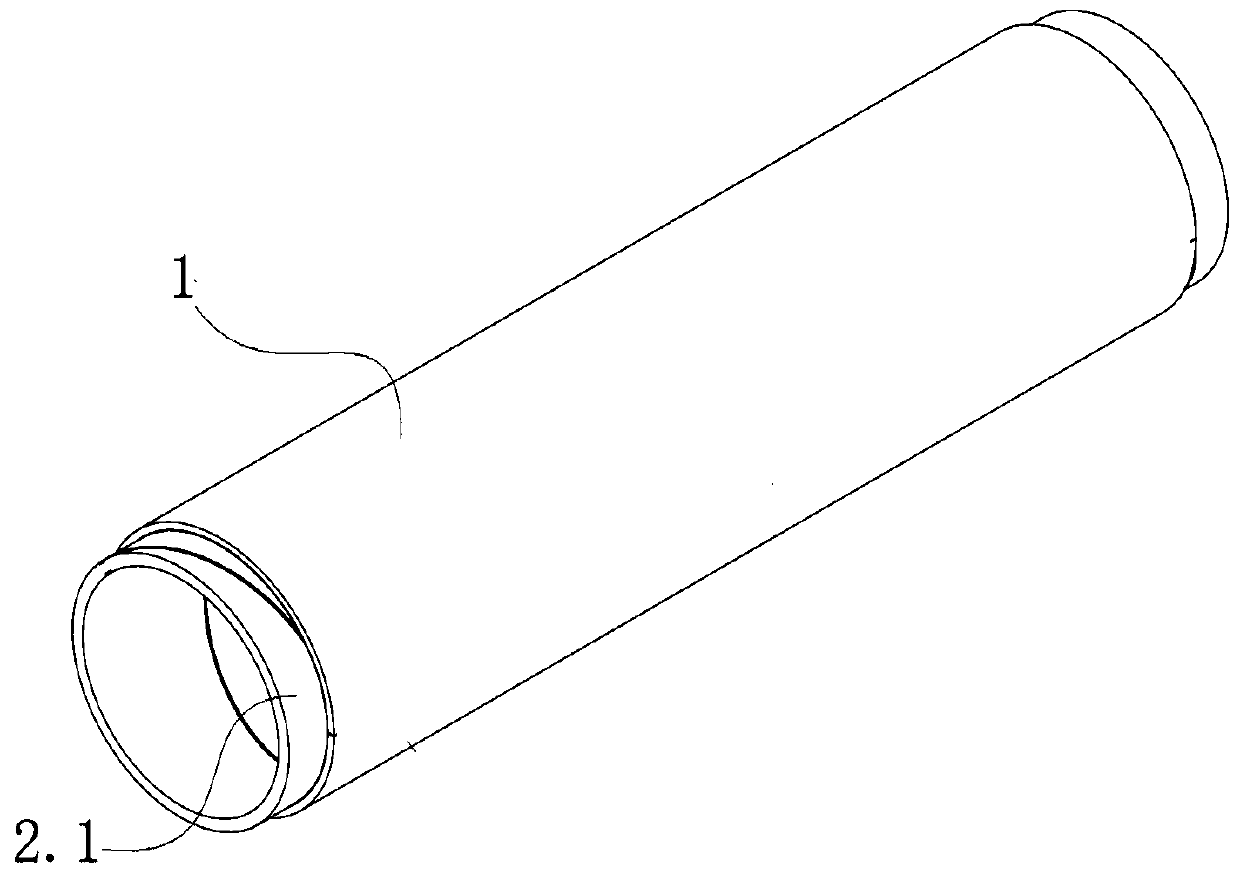

[0021] as attached Figures 1 to 5 A kind of paper core technology shown, comprises the steps:

[0022] Step 1, apply a layer of glue on the outside of the paper core bottom tube 2 that has been wound;

[0023] Step 2, the outer circumference of the elastic sleeve 1 is subjected to negative pressure suction. At this time, the inner side of the elastic sleeve 1 is in a state of normal atmospheric pressure, so that the inner diameter of the elastic sleeve 1 is in a state of continuous expansion; specifically, the elastic sleeve 1 The inner diameter is expanded to be 3mm larger than the outer diameter of the paper core bottom tube 2;

[0024] Step 3, put the paper core bottom tube 2 into the cylinder of the elastic sleeve 1 along the axis;

[0025] Step 4, release the negative pressure on the outer periphery of the elastic sleeve 1, and then make the inner diameter of ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com