Method and system for acquiring locomotive operation information by trackside detecting device

A technology for detecting equipment and operating information, which is applied to the control system of the transportation center, transportation and packaging, and railway car body parts, etc. It can solve the problem that the operating fault information cannot be obtained, and the trackside detection equipment cannot correctly identify the locomotive number and the running end position. information, inability to determine the faulty locomotive and locate the fault location, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0036] Specific embodiments of the present invention will be described in detail below in conjunction with the accompanying drawings.

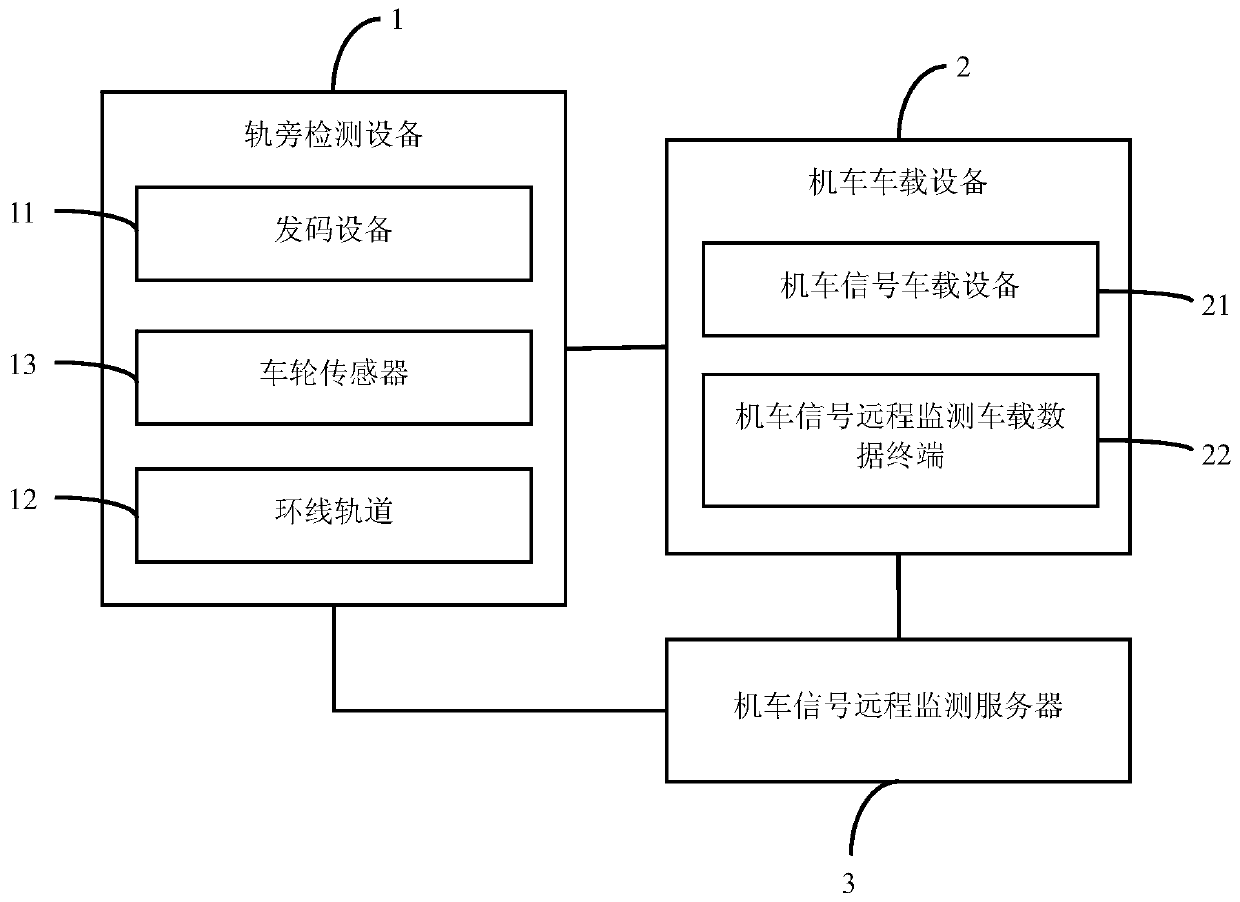

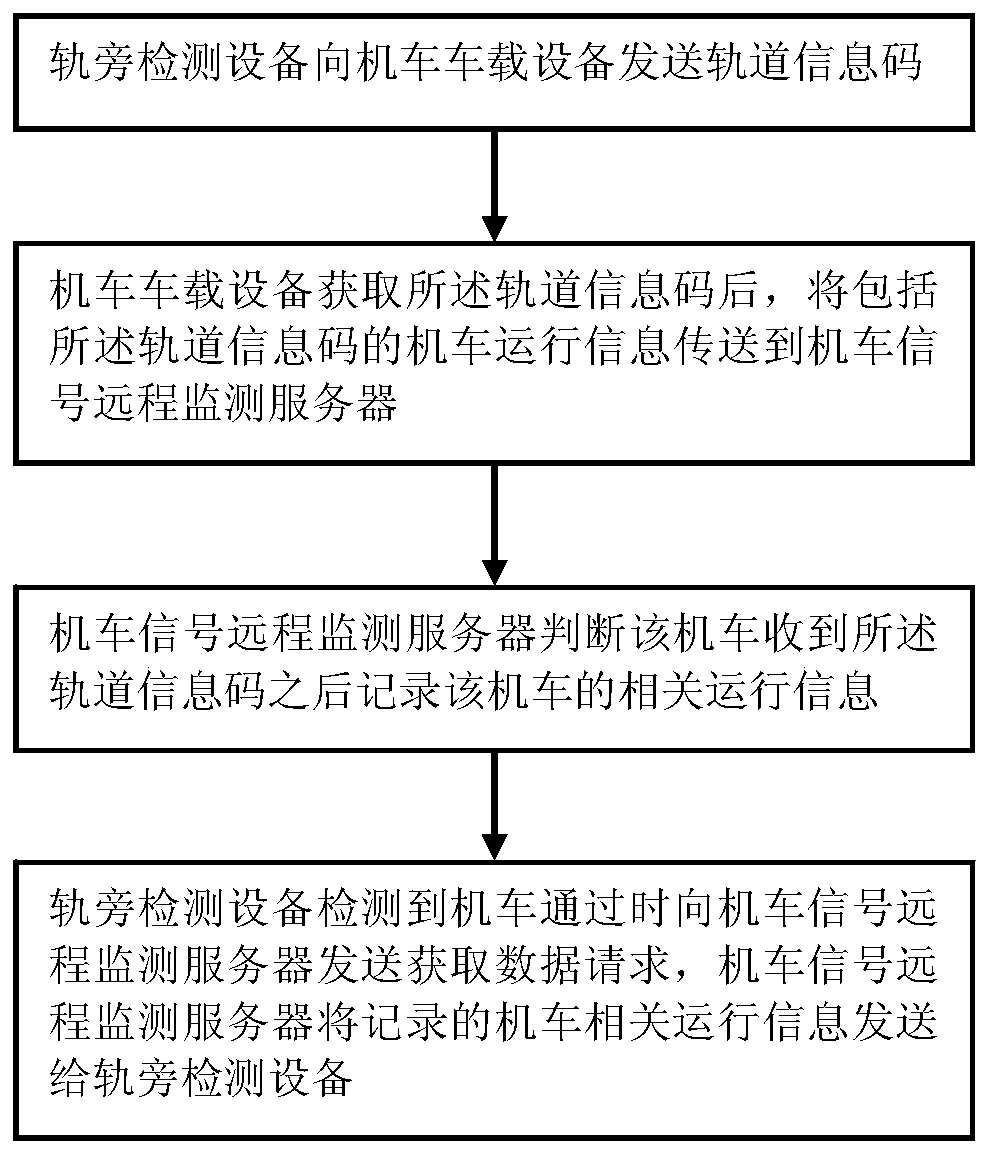

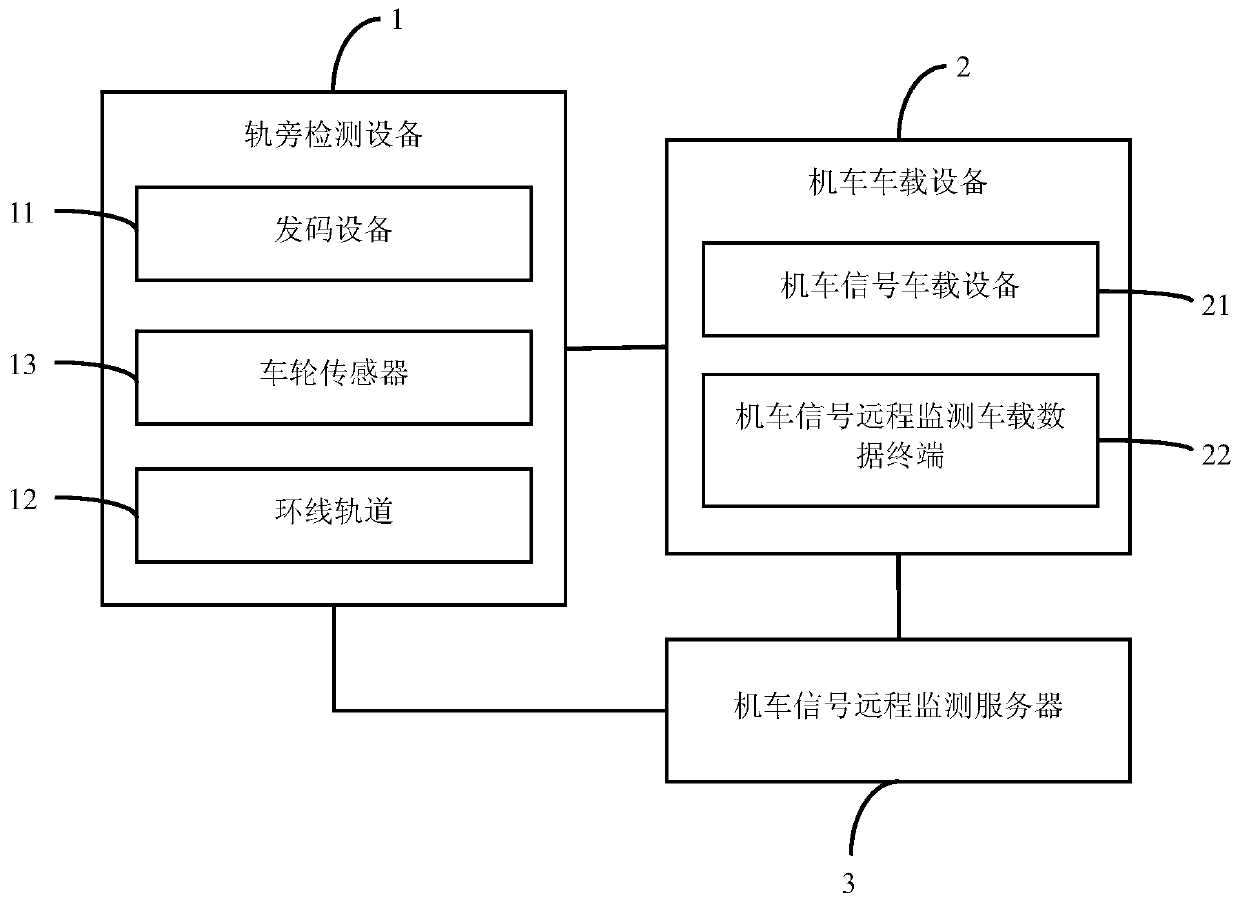

[0037] Such as figure 1 As shown, in an embodiment of the present invention, the system for obtaining locomotive operation information by trackside detection equipment includes trackside detection equipment 1 , locomotive on-board equipment 2 and locomotive signal remote monitoring server 3 . The wayside detection device 1 includes a code issuing device 11 , a loop track 12 and a wheel sensor 13 .

[0038] The trackside detection equipment 1 is used to send the track information code to the locomotive on-board equipment 2 and receive the relevant running information of the locomotive sent by the locomotive signal remote monitoring server 3 . The code sending device 11 is used to generate a track information code, and send the track information code to the circular track 12 . The loop track 12 is used to send the track information code genera...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com