Steel pipe cutting device

A cutting device, a technology for steel pipes, applied in the field of steel pipe processing, can solve problems such as trouble, sparks and debris splashing, lack of protective equipment, etc., and achieve the effect of reducing noise

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

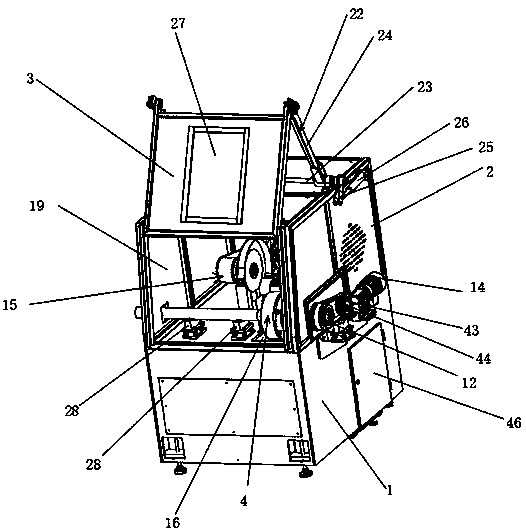

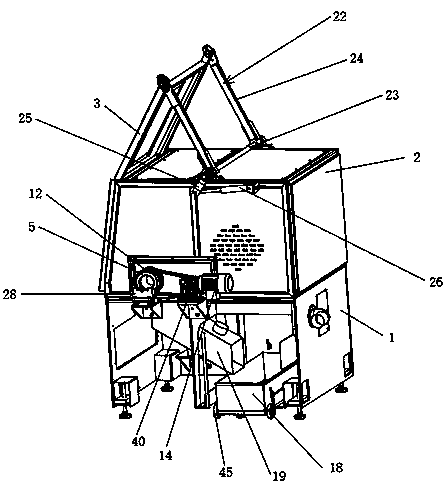

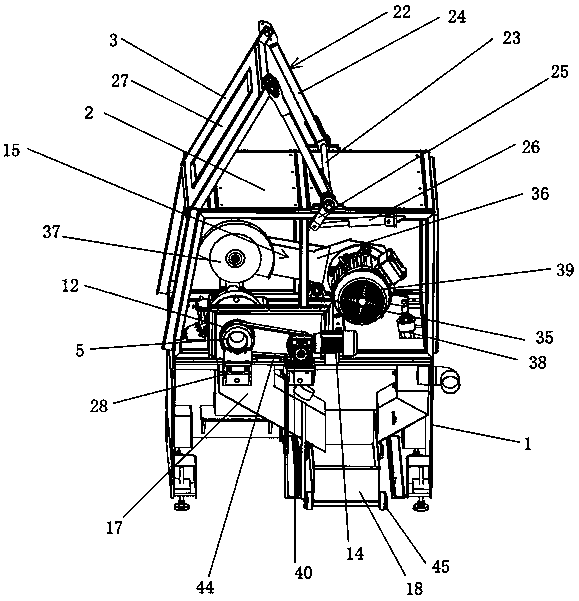

[0029] Embodiment: a kind of steel pipe cutting device, as attached Figure 1-8 Shown, comprise frame 1, the top of frame 1 is provided with protective cover 2, and the sidewall of protective cover 2 is provided with flip 3; There is a steel pipe positioning mechanism 4, such as Figure 6As shown, the steel pipe positioning mechanism 4 includes a positioning tube 5 that is fixed on the side wall of the protective cover 2 through a bearing seat, and the inner end of the positioning tube 5 is provided with a disc-shaped central block 6 with a through hole in the middle. The inside of the block 6 is provided with a bevel gear 7, and the side wall of the bevel gear 7 is provided with a spiral groove 8; the outer wall of the central block 6 is provided with a plurality of limiting chute 9 connected with the through hole, the limiting chute 9 is embedded with a block 10, and the bottom of the block 10 is provided with a convex line 11 that matches the spiral groove 8; the outer end...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com