Bending device for nut plate hemming

A technology of bending device and nut plate, which is applied in the direction of feeding device, positioning device, storage device, etc., can solve the problems of smoke and strong magnetic field on human body and environment, human body and equipment damage, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

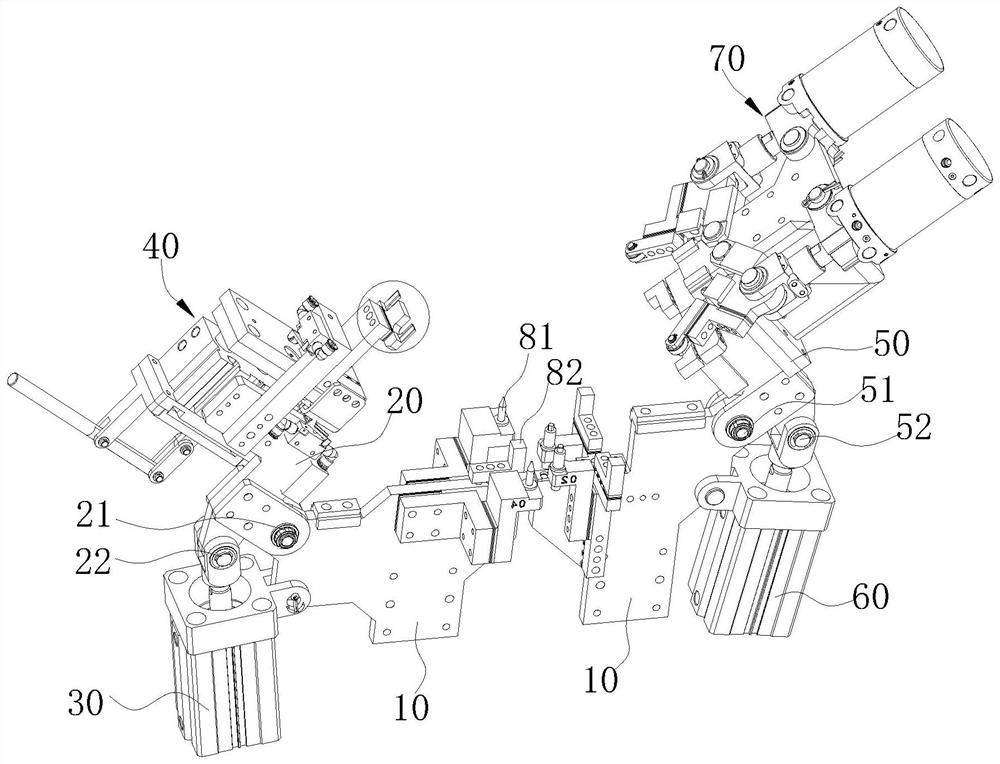

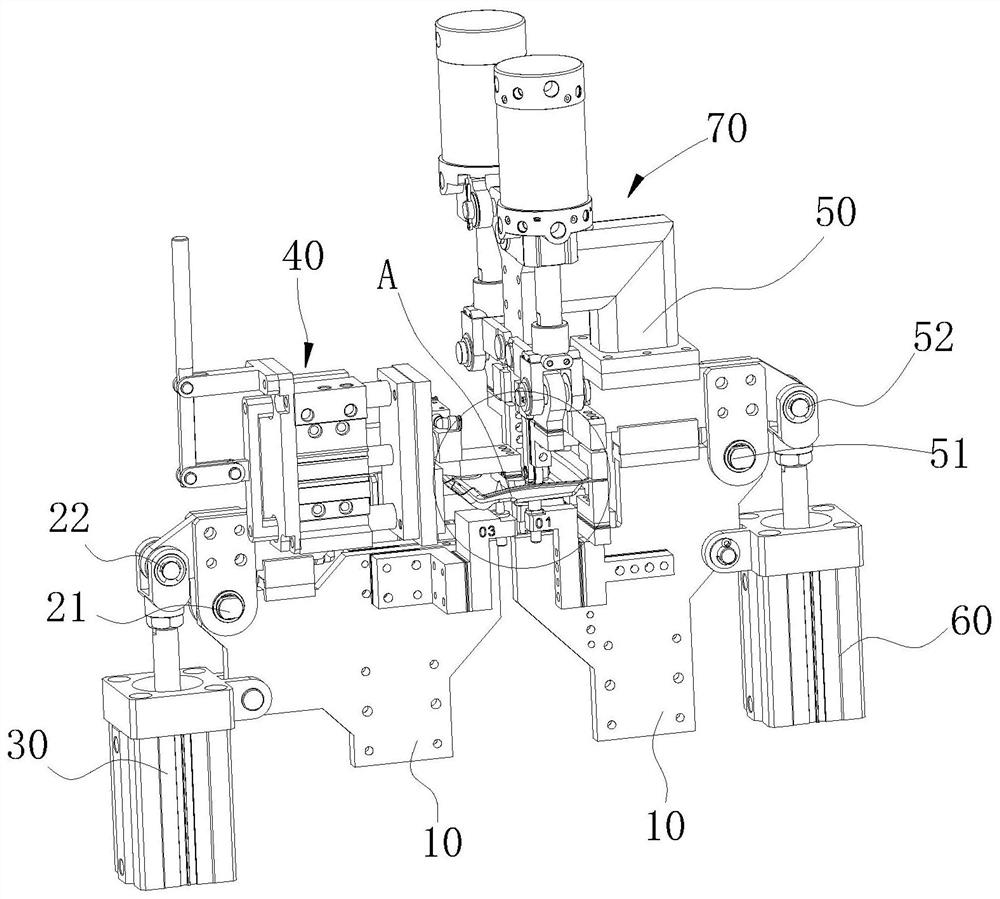

[0014] Combine below Figure 1-Figure 8 The present invention is discussed in further detail:

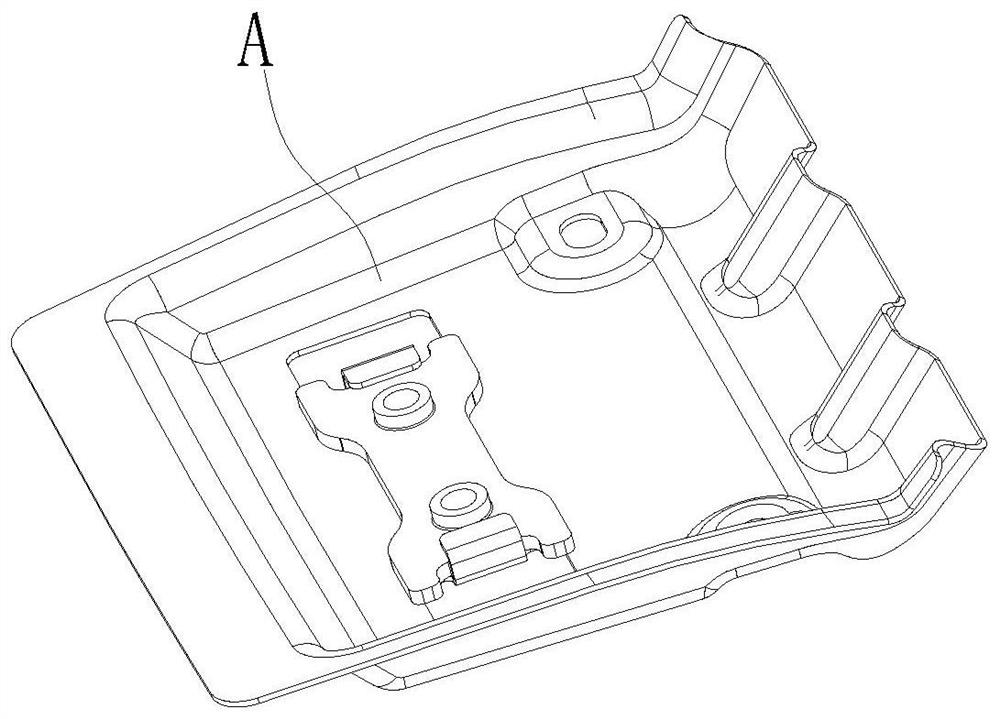

[0015] Such as figure 2 , image 3 As shown, a bending device for nut plate hemming includes a base 10 for supporting the nut plate assembly A, and above the base 10 is provided a locking unit for pressing the nut plate assembly A and performing hemming The bending unit for the bending action. First place the nut plate assembly A on the base, then the locking unit acts to lock the position of the nut plate assembly A, and then the bending unit moves to bend the edge. The edge edge process is stable and reliable.

[0016] refer to Figure 4 , the locking unit includes a first swing arm 20, the middle section of the first swing arm 20 is hinged with the base 10 through the first hinge shaft 21, and the lower end of the first swing arm 20 is connected with the first cylinder 30 through the second hinge shaft 22 The end of the piston rod is hinged, and the upper end is connected w...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com